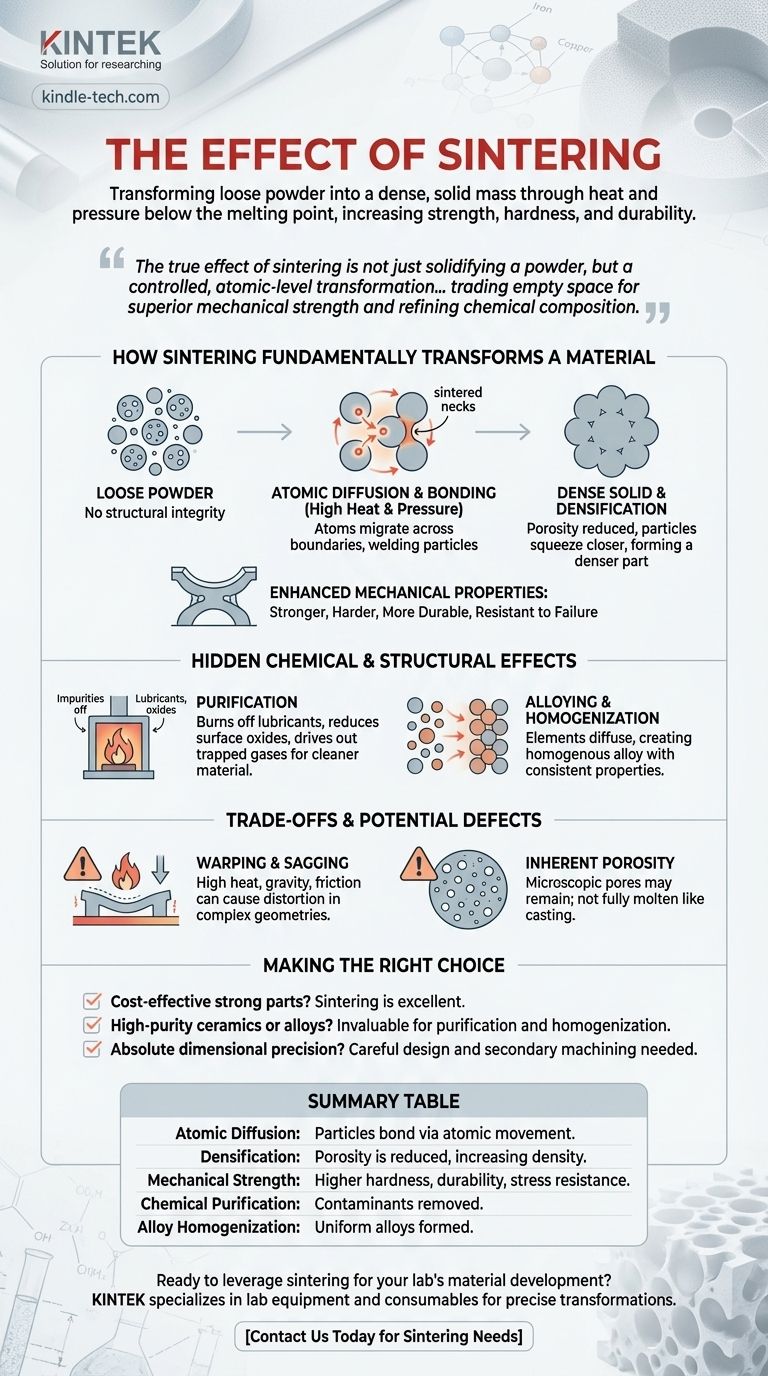

At its core, the effect of sintering is to transform a loose powder into a dense, solid mass by applying heat and pressure. This process occurs at temperatures below the material's melting point, forcing individual particles to bond together, which dramatically increases the material's strength, hardness, and durability.

The true effect of sintering is not just solidifying a powder, but a controlled, atomic-level transformation. It's a process that trades the empty space between particles for superior mechanical strength and can simultaneously refine the material's chemical composition.

How Sintering Fundamentally Transforms a Material

Sintering is a foundational process in powder metallurgy and ceramics, used to create parts that are strong and resilient from a starting material that has no structural integrity. The change is profound, occurring at the microscopic level.

The Principle of Atomic Diffusion

Sintering does not work by melting. Instead, the combination of high heat and pressure energizes the atoms within the material's particles.

This energy causes atoms to migrate, or diffuse, across the boundaries of adjacent particles. This movement forms strong atomic bonds, or "sintered necks," at the points of contact, effectively welding the particles together into a solid piece.

From Loose Powder to Dense Solid

The primary physical effect of this atomic bonding is densification. The original powder is full of pores, or empty spaces between particles.

As sintering progresses, the formation of bonds pulls the particles closer, squeezing out and reducing the size and number of these pores. This directly results in a denser, less porous final part.

The Impact on Mechanical Properties

The reduction in porosity and the creation of a continuous, bonded structure have a direct and significant impact on the part's performance.

A sintered part is vastly stronger, harder, and more durable than the compacted powder it was formed from. The elimination of internal voids removes points where cracks could easily start, making the final product much more resistant to failure under stress.

The Hidden Chemical and Structural Effects

Beyond the physical transformation, sintering also induces critical chemical changes that refine and improve the material. These effects are often just as important as the increase in density.

Purification of the Material

The high temperatures used in sintering can serve to purify the part. This process can burn off and eliminate lubricants that were used to help compact the initial powder.

Furthermore, it reduces unwanted surface oxides and can drive out trapped gases. Studies have shown significant reductions in hydrogen content and slight decreases in nitrogen, leading to a cleaner, more stable material.

Alloying and Homogenization

Sintering is also a key method for creating alloys. If the initial powder is a mix of different elements (like iron, copper, nickel, and graphite), the process facilitates their diffusion.

The heat and pressure cause these elements to spread evenly throughout the material's structure, resulting in a homogenous alloy with consistent properties throughout the part.

Understanding the Trade-offs and Potential Defects

While powerful, sintering is not without its challenges. The conditions required for the process can also introduce imperfections if not carefully controlled.

The Risk of Warping and Sagging

During the process, the part is in a state where it is not fully solid but is subjected to intense heat. The forces of gravity and friction with the furnace support can cause the part to warp, sag, or distort.

This is a critical consideration, especially for large or complex geometries, as it can lead to parts that are out of their specified dimensional tolerance.

Inherent Porosity

While sintering drastically reduces porosity, it rarely eliminates it completely. Some microscopic pores may remain in the final part.

For most applications, this residual porosity is acceptable. However, for applications demanding absolute maximum density and strength, a part made from a fully molten process (like casting or forging) might be superior, though often at a higher cost.

Making the Right Choice for Your Goal

Understanding the effects of sintering allows you to decide when it is the right manufacturing process for your needs.

- If your primary focus is cost-effective production of strong, complex parts: Sintering is an excellent choice for achieving high strength and creating net-shape or near-net-shape components with minimal machining.

- If your primary focus is creating high-purity ceramics or specialized alloys: The process is invaluable for its ability to densify materials while simultaneously burning off contaminants and homogenizing elements.

- If your primary focus is absolute dimensional precision: You must design the process carefully to mitigate warping and consider that secondary machining may be required to meet the tightest tolerances.

Ultimately, viewing sintering as a tool for atomic-level material refinement empowers you to create robust components with carefully tailored properties.

Summary Table:

| Effect of Sintering | Key Outcome |

|---|---|

| Atomic Diffusion | Particles bond via atomic movement, forming a solid structure. |

| Densification | Porosity is reduced, increasing material density. |

| Mechanical Strength | Parts gain higher hardness, durability, and resistance to stress. |

| Chemical Purification | Contaminants like lubricants and oxides are removed. |

| Alloy Homogenization | Mixed powders diffuse to form uniform alloys with consistent properties. |

Ready to leverage sintering for your lab's material development? KINTEK specializes in lab equipment and consumables, providing reliable sintering solutions to help you achieve precise material transformations. Whether you're creating high-strength alloys or pure ceramics, our expertise ensures optimal results. Contact us today to discuss how we can support your laboratory's sintering needs!

Visual Guide

Related Products

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Spark Plasma Sintering Furnace SPS Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What is the pressure for vacuum sintering? Achieve Optimal Material Purity and Density

- What is a sintering furnace? A Guide to High-Temperature Materials Processing

- What is the impact factor of powder metallurgy progress? A 2022 Analysis & Context

- What is the density of sintered material? A Design Choice for Performance, Not a Fixed Number

- What temperature does tungsten carbide sinter at? Master the 1350°C-1500°C Liquid-Phase Sintering Process