In thin film deposition, temperature is the single most influential parameter controlling a film's final structure and performance. Higher temperatures generally provide atoms with more energy, allowing them to arrange into denser, more ordered structures with better adhesion. However, this is balanced against the thermal limitations of the substrate and the potential for creating undesirable internal stress.

The "best" deposition temperature is not a fixed value but a strategic choice. It requires balancing the pursuit of ideal film properties—like density and adhesion—against the practical constraints of your substrate and the risk of creating performance-killing internal stress.

The Fundamental Role of Temperature: Surface Mobility

At the atomic level, temperature governs the energy of the atoms arriving at the substrate surface. This energy dictates how they behave in the first few moments after landing, which in turn defines the entire structure of the film.

What is an "Adatom"?

An "adatom" is simply an atom that has landed (adsorbed) on the substrate surface but has not yet become locked into its final position within the film's structure. The behavior of these adatoms is the key to understanding temperature effects.

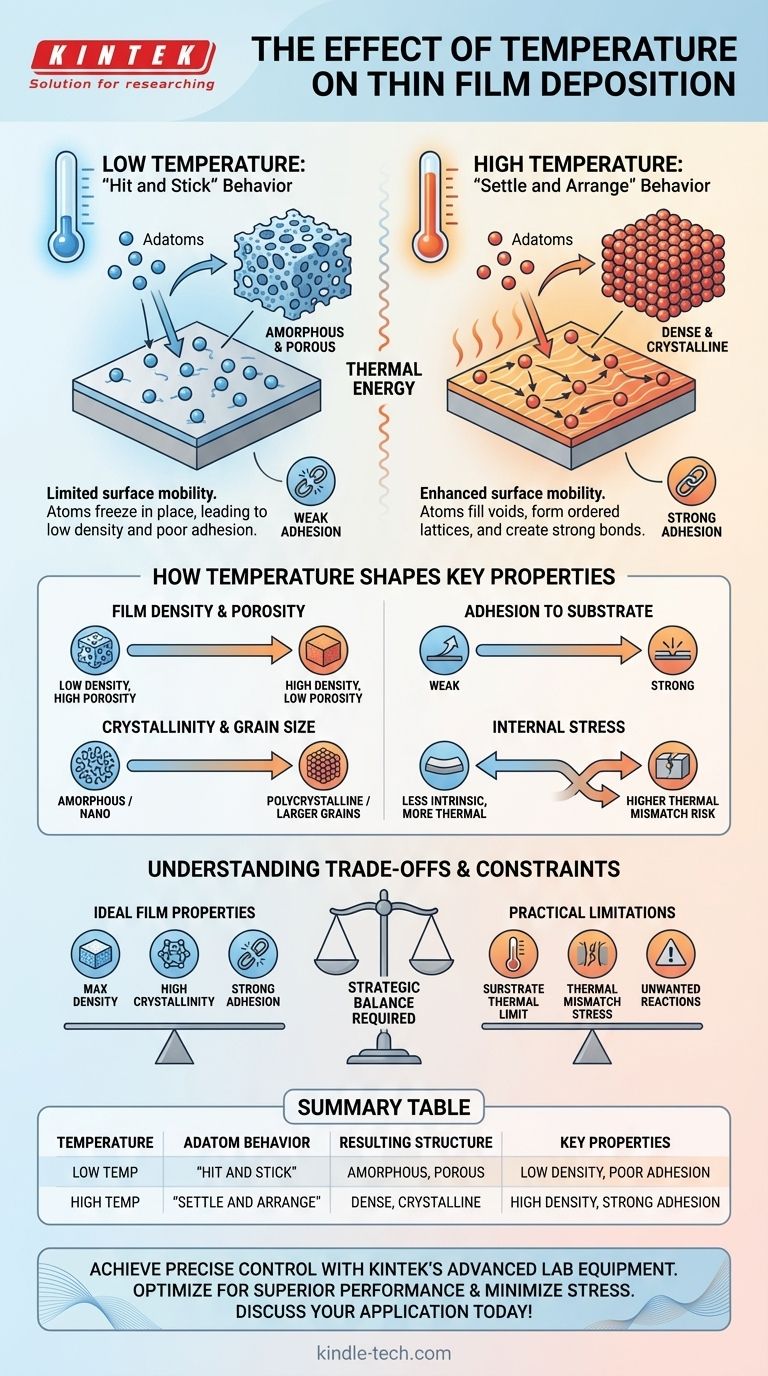

Low Temperature: "Hit and Stick" Behavior

At low substrate temperatures, arriving atoms have very little thermal energy. They essentially "stick" where they land, with minimal movement across the surface.

This leads to a film structure that is often amorphous (disordered) and porous, with lower density. The limited mobility prevents atoms from filling in microscopic voids or finding more stable, crystalline arrangements.

High Temperature: "Settle and Arrange" Behavior

At higher temperatures, adatoms have significant thermal energy. This allows them to diffuse across the surface, moving around until they find a more energetically favorable location.

This enhanced surface mobility allows adatoms to fill in voids, form ordered crystal lattices, and create stronger bonds with the substrate. The result is a film that is denser, more crystalline, and often has better adhesion.

How Temperature Shapes Key Film Properties

The difference between "hit and stick" and "settle and arrange" behavior has direct, measurable consequences on the final characteristics of the thin film.

Film Density and Porosity

Higher temperatures directly lead to higher film density and lower porosity. The increased adatom mobility allows particles to settle into the "valleys" of the growing film's surface, eliminating the microscopic voids that create a porous, low-density structure.

Adhesion to the Substrate

Good adhesion relies on strong bonding at the film-substrate interface. Higher temperatures promote this in two ways: they provide the energy needed for strong chemical bonds to form and can encourage a small amount of interdiffusion, where atoms from the film and substrate mix slightly, creating a strong, graded interface.

Crystallinity and Grain Size

Forming an ordered crystal lattice requires energy. Low-temperature depositions often result in amorphous or nanocrystalline films because the adatoms lack the energy to arrange themselves. As temperature increases, the film becomes more polycrystalline, and the average crystal grain size typically grows larger.

Internal Stress

Stress is a critical property that can cause films to crack or peel off. Temperature's role is complex. While higher mobility can help relieve some intrinsic stress, the biggest factor is thermal stress. This occurs when a film deposited at high temperature cools down, and it shrinks at a different rate than the substrate due to a mismatch in their Coefficients of Thermal Expansion (CTE).

Understanding the Trade-offs and Constraints

Choosing a high temperature is not always possible or desirable. The practical limitations of the application often dictate the processing window.

The Substrate's Thermal Limit

This is the most common constraint. Many substrates cannot withstand high temperatures. Depositing on polymers (plastics), flexible electronics, or substrates with pre-existing integrated circuits (like a CMOS wafer) forces the use of low-temperature processes to avoid melting, warping, or damaging the underlying components.

The Problem of Thermal Mismatch Stress

Even if a substrate can handle the heat, depositing a film at 500°C onto a substrate with a different CTE will generate enormous stress as the system cools to room temperature. This stress can be strong enough to crack a brittle ceramic film or cause it to delaminate completely.

Unwanted Chemical Reactions

High temperatures can act as a catalyst for unwanted reactions. The depositing film material might react with the substrate or with residual gases in the vacuum chamber, leading to contamination, the formation of an undesirable interface layer, and compromised film properties.

Selecting the Right Temperature for Your Goal

The ideal temperature is entirely dependent on your primary objective for the thin film.

- If your primary focus is maximum film density and crystallinity: You should use the highest temperature that your substrate and film material can safely tolerate without causing damage or unwanted reactions.

- If your primary focus is minimizing film stress for better adhesion: You may need to deposit at a lower temperature to avoid thermal mismatch stress or carefully select a substrate with a CTE that closely matches your film.

- If you are depositing on a temperature-sensitive substrate: You are forced into a low-temperature regime and must instead optimize other parameters (like deposition rate, chamber pressure, or using ion-assisted deposition) to improve film quality.

Ultimately, mastering temperature control is about strategically balancing the physics of atom mobility against the practical limitations of your materials and application.

Summary Table:

| Temperature Level | Adatom Behavior | Resulting Film Structure | Key Properties |

|---|---|---|---|

| Low Temperature | 'Hit and Stick' | Amorphous, Porous | Low Density, Poor Adhesion |

| High Temperature | 'Settle and Arrange' | Dense, Crystalline | High Density, Strong Adhesion |

Achieve precise control over your thin film properties with KINTEK's advanced lab equipment.

Whether you are developing high-performance coatings, semiconductor devices, or flexible electronics, the right deposition temperature is critical. KINTEK specializes in providing reliable lab equipment and consumables that deliver the precise temperature control and stability your research demands.

Our solutions help you:

- Optimize film density and crystallinity for superior performance.

- Minimize internal stress to prevent cracking and delamination.

- Work with temperature-sensitive substrates without compromising quality.

Let's discuss your specific application. Contact our experts today to find the perfect equipment for your laboratory's thin film deposition needs.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

People Also Ask

- What is the chemical vapor deposition technique involved in? A Guide to Thin-Film Synthesis

- What are the disadvantages of chemical vapor deposition? High Costs, Safety Risks, and Material Limitations

- What are the different types of CVD in nanotechnology? Choose the Right Method for Your Materials

- What is a deposition system? The Engine Behind Modern Electronics and Advanced Materials

- What are the potential applications of graphene? Unlocking Next-Gen Electronics, Energy, and Materials

- What challenges are associated with the use of CVD in CMOS technology? Overcoming Cost and Precision Barriers

- What role does high-purity Argon gas serve as a carrier gas? Enhance Alumina Coating Purity & Stability

- What is chemical vapour deposition of graphene synthesis? A Guide to Scalable, High-Quality Graphene Production