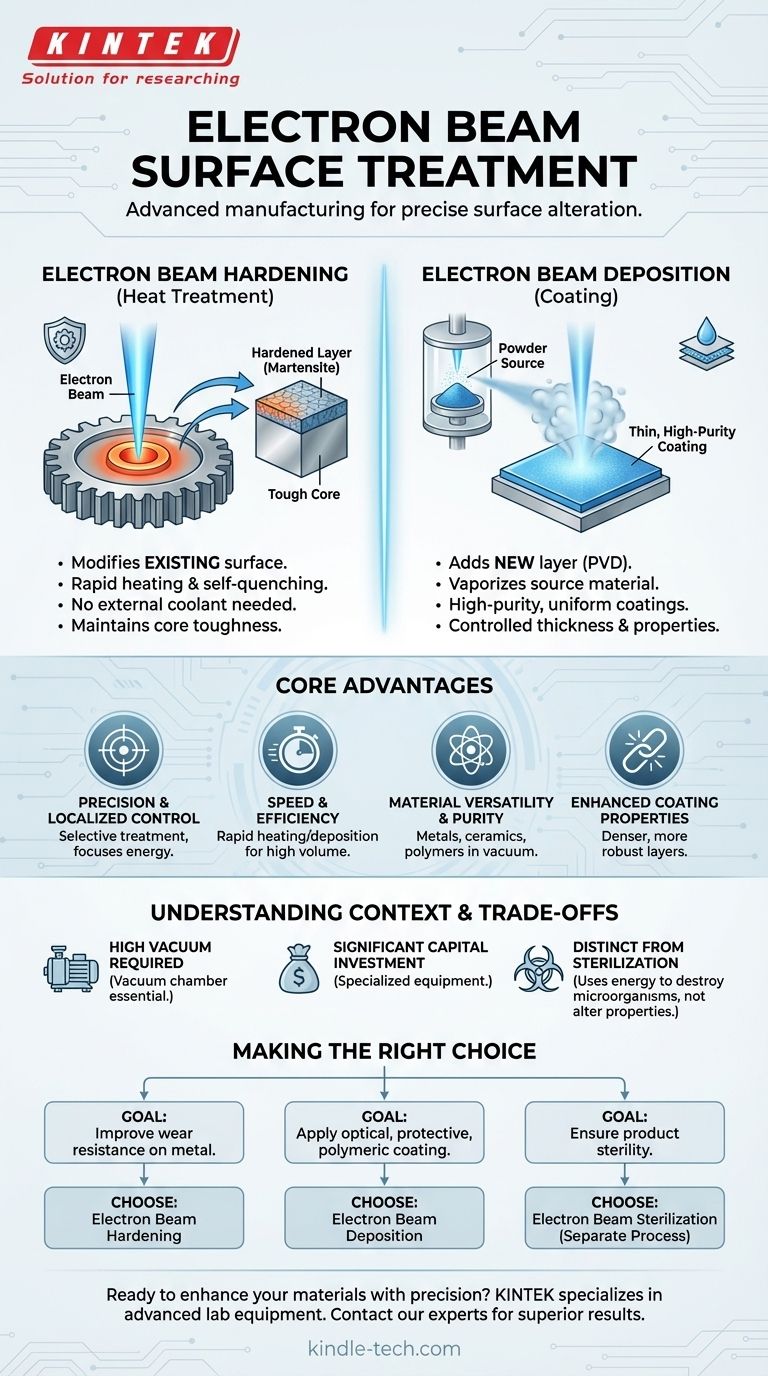

In short, electron beam surface treatment is a category of advanced manufacturing processes that use a highly focused beam of electrons in a vacuum to precisely alter the surface properties of a material. This is done primarily in two ways: by rapidly heating and cooling the existing surface to harden it, or by vaporizing a source material to deposit a thin, high-performance coating onto the surface.

The core principle is the precise delivery of energy. An electron beam can either induce a phase transformation within a material's surface for hardening or provide the energy to vaporize another material for deposition, offering exceptional control over the final surface characteristics.

Two Primary Methods of Surface Modification

Electron beam technology is not a single process but a platform for achieving different outcomes. The two most common applications in materials engineering are hardening and deposition, each serving a distinct purpose.

Electron Beam Hardening (Heat Treatment)

This method modifies the properties of the existing surface. It is most commonly applied to metals like steel and cast iron.

The electron beam provides a high power-density that rapidly heats a localized area of the material above its critical transformation temperature (the austenitic temperature in steel).

Once the beam moves on, the surrounding bulk of the cool material acts as an extremely efficient heat sink, causing a "self-quenching" effect. This rapid cooling transforms the surface layer into a very hard and wear-resistant microstructure, like martensite.

Crucially, this process requires no external coolant and does not affect the toughness of the material's core.

Electron Beam Deposition (Coating)

This method involves adding a new layer of material to the surface. It is a physical vapor deposition (PVD) technique.

Inside a vacuum chamber, the electron beam is aimed at a source material, such as a powder or granule. The intense energy from the beam vaporizes this material.

This resulting vapor then travels and condenses onto the target object (the substrate), forming a thin, uniform, and often highly pure coating.

The process is managed by computer control, which precisely regulates heating, vacuum levels, and substrate positioning to achieve coatings with pre-specified thicknesses and properties.

The Core Advantages of Using an Electron Beam

Engineers and manufacturers choose this technology for its unique combination of speed, precision, and material flexibility.

Precision and Localized Control

The beam's energy can be focused on very small areas, allowing for selective treatment. This means you can harden just the gear teeth on a large component or coat a specific part of an optical lens without affecting the rest of the object.

Speed and Efficiency

Electron beam processes are typically very fast. The high energy density allows for rapid heating in hardening applications and high deposition rates for coatings, making it ideal for high-volume commercial production.

Material Versatility and Purity

For deposition, the electron beam can vaporize a wide array of materials, including metals, ceramics, and polymers. The process occurs in a vacuum, which minimizes contamination and results in very pure, dense coatings.

Enhanced Coating Properties

The deposition process can be augmented with an ion beam to increase the adhesion energy of the coating. This results in a denser, more robust final layer with less internal stress.

Understanding the Trade-offs and Context

While powerful, electron beam technology has specific requirements and is not a universal solution. Understanding its context is key to its proper application.

Heat Treatment vs. Deposition

It is critical to distinguish between these two processes. Hardening enhances the inherent properties of the base material. Deposition adds a new material with entirely different properties to the surface.

Equipment and Environment

Electron beam systems require a high vacuum to operate, which means processing must be done inside a vacuum chamber. The equipment itself involves high-voltage power supplies and electron guns, representing a significant capital investment.

A Note on Sterilization

You may also encounter the term "electron beam" in the context of sterilization. While it uses the same core technology—a beam of electrons—its purpose is entirely different. It uses the beam's energy to destroy microorganisms on products like medical devices, not to alter the material's mechanical or optical properties.

Making the Right Choice for Your Goal

To select the appropriate electron beam process, you must first define your primary objective for the material's surface.

- If your primary focus is improving wear resistance on a metal part: Electron beam hardening is the ideal method for creating a durable, hardened case on a specific area while maintaining the core's toughness.

- If your primary focus is applying a precise optical, protective, or polymeric coating: Electron beam deposition offers a fast, high-purity method for creating high-performance thin films from a wide range of materials.

- If your primary focus is ensuring the sterility of a product: Electron beam irradiation is a separate, FDA-approved process designed for rapid and effective sterilization.

Ultimately, electron beam surface treatment offers a suite of powerful, high-precision tools for fundamentally changing the way a material interacts with its environment.

Summary Table:

| Method | Primary Goal | Key Process | Key Outcome |

|---|---|---|---|

| Electron Beam Hardening | Improve wear resistance | Rapidly heats & self-quenches the existing surface | Hard, wear-resistant surface; tough core |

| Electron Beam Deposition | Apply a functional coating | Vaporizes a source material to coat a substrate | Thin, uniform, high-purity coating |

| Electron Beam Sterilization | Destroy microorganisms | Irradiates surface with electron energy | Sterile product (medical devices, etc.) |

Ready to enhance your materials with precision electron beam technology?

KINTEK specializes in advanced lab equipment for surface engineering. Whether you are developing hardened components or high-performance coatings, our expertise and solutions can help you achieve superior results.

Contact our experts today to discuss how we can support your laboratory's specific needs in materials science and surface treatment.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- E Beam Crucibles Electron Gun Beam Crucible for Evaporation

- Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

- Platinum Sheet Electrode for Laboratory and Industrial Applications

People Also Ask

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating