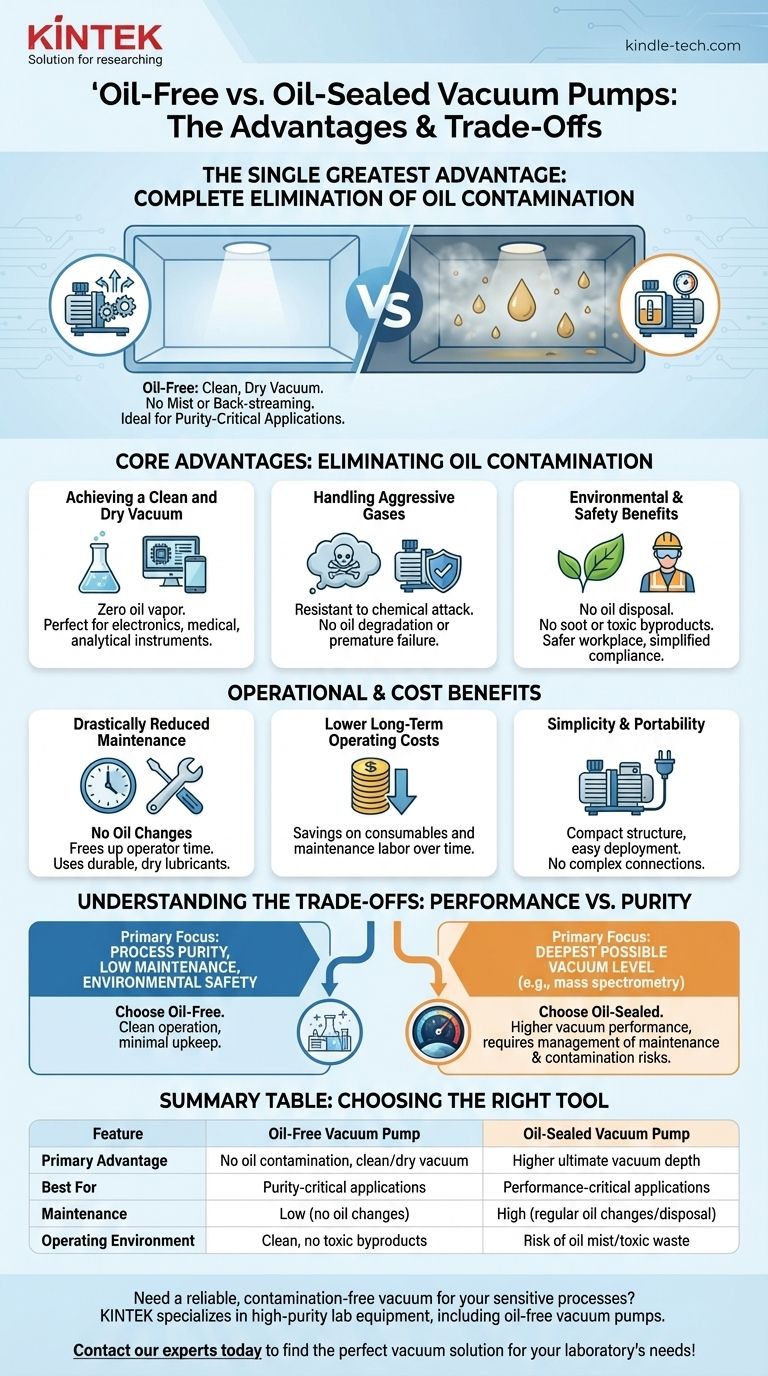

The single greatest advantage of using an oil-free vacuum pump is the complete elimination of oil contamination. Because they operate without any pump oil, they provide a clean, dry vacuum, preventing oil mist or back-streaming from polluting your vacuum chamber or process. This makes them inherently better suited for applications where purity is paramount.

The choice between an oil-free and an oil-sealed vacuum pump is not about which is "better" overall, but which is the right tool for your specific goal. Oil-free pumps prioritize cleanliness and low maintenance, while oil-sealed pumps deliver higher vacuum performance at the cost of potential contamination and increased upkeep.

The Core Advantage: Eliminating Oil Contamination

The fundamental difference in design—the absence of oil—is the source of an oil-free pump's primary benefits. This single factor has significant implications for process purity, safety, and the types of materials you can handle.

Achieving a Clean and Dry Vacuum

Oil-sealed pumps, by their nature, risk introducing oil vapor into the vacuum system. This is unacceptable in sensitive applications like electronics manufacturing, medical devices, or analytical instrumentation.

Oil-free pumps create a completely dry vacuum, ensuring the integrity of your process is never compromised by hydrocarbon-based contaminants.

Handling Aggressive Gases

Aggressive or corrosive gases can react with and degrade the oil in an oil-sealed pump. This chemical breakdown reduces pump performance and can lead to premature failure.

Because there is no oil to contaminate, oil-free pumps are far more resistant to chemical attack and maintain their stability when handling these challenging gases.

Environmental and Safety Benefits

Oil-sealed pumps require the regular disposal of used oil, which is often considered toxic waste. They can also produce soot or an oil mist during operation.

Oil-free pumps eliminate this entire waste stream, producing no soot or toxic byproducts. This simplifies compliance and creates a safer, cleaner work environment.

The Operational and Cost Benefits

Beyond process purity, the oil-free design simplifies operation and reduces the total cost of ownership over the pump's lifetime.

Drastically Reduced Maintenance

The most frequent maintenance task for an oil-sealed pump is monitoring and changing the oil. This is a recurring cost in both materials and labor.

Oil-free pumps eliminate the need for oil changes, freeing up operator time and reducing routine service requirements. Many use durable, dry lubricants and are designed for long service intervals.

Lower Long-Term Operating Costs

While the initial purchase price can vary, the total cost of ownership for an oil-free pump is often lower. This is a direct result of savings on consumable oil and reduced maintenance labor.

Simplicity and Portability

Oil-free pumps often feature a more compact and simple structure. They operate anywhere with an electrical outlet and do not require connections to water sources or complex installation, making them highly portable and easy to deploy.

Understanding the Trade-offs: Performance vs. Purity

The decision to use an oil-free pump is not without compromise. The primary trade-off is ultimate vacuum capability.

The Limitation of Vacuum Power

The oil in a sealed pump serves a critical function: it creates a tight seal that allows the pump to achieve very deep vacuum levels.

Oil-free pumps, lacking this sealing fluid, generally have lower maximum vacuum power and smaller pumping capacities compared to their oil-sealed counterparts.

When to Choose an Oil-Sealed Pump

For applications that absolutely require a very deep, consistent vacuum—such as in mass spectrometry or freeze-drying—an oil-sealed rotary vane pump is often the superior choice. The performance benefit outweighs the maintenance burden and contamination risk, which can be managed with proper trapping and procedures.

Making the Right Choice for Your Application

Selecting the correct pump requires a clear understanding of your primary objective.

- If your primary focus is process purity, low maintenance, or environmental safety: An oil-free pump is the clear choice for its clean operation and minimal upkeep.

- If your primary focus is achieving the deepest possible vacuum level: An oil-sealed pump, like a rotary vane pump, provides the necessary high performance, provided you can manage the maintenance and contamination risks.

- If your primary focus is portability and ease of use for general applications: An oil-free pump's compact, self-contained design offers unmatched convenience.

Ultimately, understanding this fundamental trade-off between cleanliness and vacuum depth empowers you to select the ideal pump for your specific needs.

Summary Table:

| Feature | Oil-Free Vacuum Pump | Oil-Sealed Vacuum Pump |

|---|---|---|

| Primary Advantage | No oil contamination, clean/dry vacuum | Higher ultimate vacuum depth |

| Best For | Purity-critical applications (e.g., electronics, medical) | Performance-critical applications (e.g., mass spectrometry) |

| Maintenance | Low (no oil changes) | High (regular oil changes and disposal) |

| Operating Environment | Clean, no toxic byproducts | Risk of oil mist and toxic waste |

Need a reliable, contamination-free vacuum for your sensitive processes?

KINTEK specializes in high-purity lab equipment, including oil-free vacuum pumps designed for applications where cleanliness is paramount. Our pumps ensure your processes remain uncontaminated, reducing maintenance and protecting your valuable work.

Contact our experts today to find the perfect vacuum solution for your laboratory's needs!

Visual Guide

Related Products

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Laboratory Rotary Vane Vacuum Pump for Lab Use

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- 30T 40T Split Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- Why are zirconia grinding balls preferred for HE-O-MIEC mixing? Ensure Purity & Precision in Synthesis

- Why are zirconia milling jars preferred as reaction vessels for sulfide solid electrolyte powders? Ensure High Purity

- How do grinding balls contribute to the mechanical alloying process of Al-Cu powders? Optimize Energy & Grain Refinement

- What is the lining material for furnace? A Guide to High-Temperature Refractories

- Why use high-strength steel grinding balls and control ball-to-powder ratio for ODS FeCrAl? Optimize Mechanical Alloying

- Why is precision temperature control equipment necessary for amorphous LLZTO coatings? Protect Your Cathode Integrity

- Why are cross-shaped magnetic stirrers used in micro-CSTRs for solid particles? Boost Mixing & Prevent Clogging

- What is the importance of a vacuum pump for Schottky hybrid interfaces? Achieve Atomic-Level Purity and Bonding