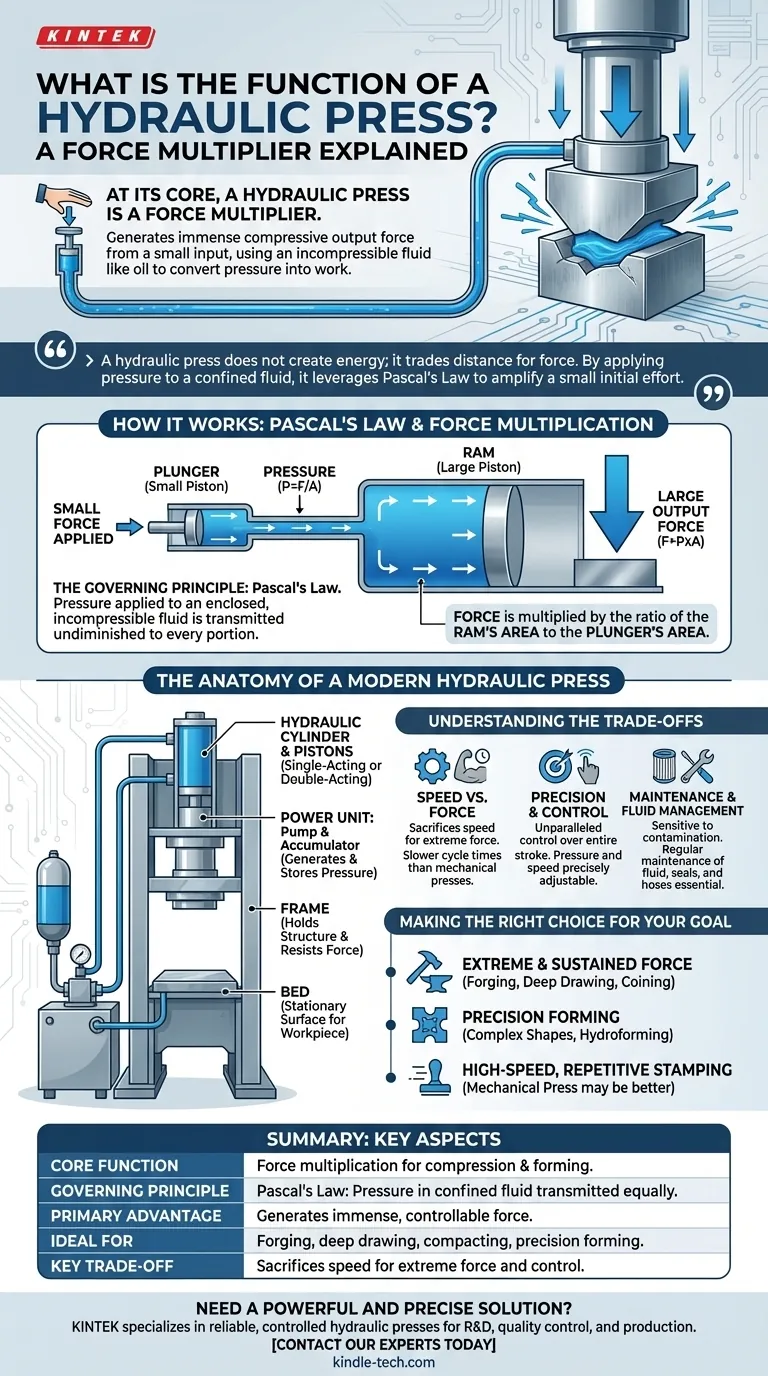

At its core, a hydraulic press is a force multiplier. It is a machine designed to generate an immense compressive output force by applying a comparatively small input force. Using an incompressible fluid like oil, it masterfully converts pressure into work, allowing it to press, crush, form, and shape materials with a level of power that mechanical systems struggle to match.

A hydraulic press does not create energy; it trades distance for force. By applying pressure to a confined fluid, it leverages a fundamental principle of physics—Pascal's Law—to amplify a small initial effort over a small piston into a powerful output force over a larger one.

How a Hydraulic Press Achieves Force Multiplication

The genius of the hydraulic press lies not in complex machinery but in the simple, elegant application of fluid dynamics.

The Governing Principle: Pascal's Law

The entire operation is based on Pascal's Law. This principle states that pressure applied to an enclosed, incompressible fluid is transmitted undiminished to every portion of the fluid and the walls of the containing vessel.

In simple terms, any pressure you create at one point in the system is felt equally everywhere else within that system.

The Key Components and Process

A basic hydraulic system consists of two connected cylinders, each with a piston, filled with fluid.

- A small force is applied to the smaller piston, often called the plunger. This creates pressure in the fluid (

Pressure = Force / Area). - This pressure is transmitted equally throughout the fluid.

- The same pressure now acts on the larger piston, known as the ram, which has a much greater surface area.

Because the force is the product of pressure and area (Force = Pressure x Area), and the pressure is constant, the larger area of the ram multiplies the initial force significantly.

The Anatomy of a Modern Hydraulic Press

While the principle is simple, a modern industrial press integrates several key systems to function effectively and reliably.

The Hydraulic Cylinder and Pistons

This is the heart of the machine, containing the fluid and the ram that performs the work. A press can be single-acting, where hydraulic pressure moves the ram in one direction (usually down) and gravity or springs return it, or double-acting, where pressure is used for both extension and retraction.

The Power Unit: Pump and Accumulator

A hydraulic pump is used to move the fluid and generate the required pressure.

For applications needing sudden bursts of high force, the system often includes a hydraulic accumulator. This device stores high-pressure liquid from the pump and releases it on demand, ensuring the ram has the necessary force when it's needed most.

The Frame and Bed

The immense forces generated by the ram must be contained. The frame is the robust structure that holds the hydraulic cylinder and resists the upward force, while the bed is the stationary surface upon which the workpiece rests.

Understanding the Trade-offs

No technology is without its compromises. Acknowledging them is key to choosing the right tool for the job.

Speed vs. Force

The primary trade-off in a hydraulic press is speed for force. To move the large ram a small distance, the small plunger must travel a much larger distance. This makes hydraulic presses exceptionally powerful but often slower in cycle time compared to mechanical presses.

Precision and Control

While potentially slower, hydraulic systems offer unparalleled control. The force can be held constant throughout the entire stroke, and both pressure and speed can be precisely adjusted. For even greater control, some presses use an array of smaller rams instead of one large one.

Maintenance and Fluid Management

Hydraulic systems are sensitive to contamination. The hydraulic fluid must be kept clean, and the system must be free of leaks to operate efficiently and safely. Regular maintenance of seals, hoses, and filters is essential.

Making the Right Choice for Your Goal

Selecting a hydraulic press depends entirely on the requirements of your application.

- If your primary focus is generating extreme and sustained force: The hydraulic press is unparalleled for forging, deep drawing, coining, or compacting materials where immense, controlled pressure is required.

- If your primary focus is precision forming: A modern hydraulic press offers superior control over the entire stroke, making it ideal for forming complex shapes or for hydroforming applications.

- If your primary focus is high-speed, repetitive stamping: A mechanical press may be a more suitable choice, as it typically offers faster cycle times for simpler, high-volume operations.

Ultimately, the function of a hydraulic press is to provide a powerful and controllable solution for shaping the world around us.

Summary Table:

| Key Aspect | Description |

|---|---|

| Core Function | Force multiplication for compression and forming. |

| Governing Principle | Pascal's Law: Pressure in a confined fluid is transmitted equally. |

| Primary Advantage | Generates immense, controllable force. |

| Ideal For | Forging, deep drawing, compacting, and precision forming. |

| Key Trade-off | Sacrifices speed for extreme force and control. |

Need a powerful and precise solution for your lab's material testing or sample preparation?

KINTEK specializes in lab equipment, including hydraulic presses designed for reliability and control. Our presses are ideal for R&D, quality control, and production tasks requiring consistent, high-pressure force.

Contact our experts today to find the perfect hydraulic press for your specific laboratory needs and discover how KINTEK can enhance your workflow.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

People Also Ask

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.