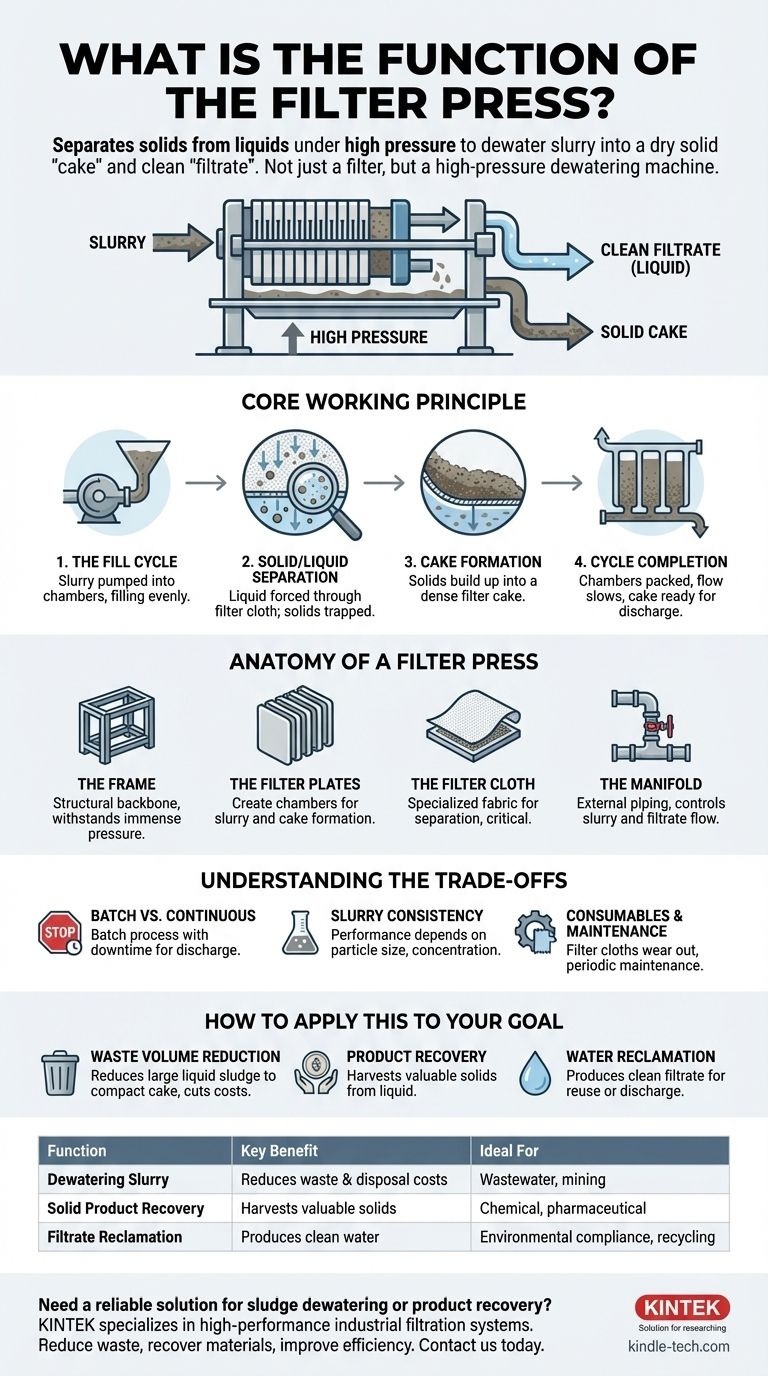

The primary function of a filter press is to separate solids from liquids. It operates under high pressure to force a liquid slurry through a filter medium, which traps the solid particles and allows a clean liquid, or filtrate, to pass through. This process dewaters the slurry, transforming it into a compressed, dry solid "cake."

A filter press is best understood not as a simple filter, but as a high-pressure dewatering machine. Its core value lies in transforming a high-volume liquid slurry into two manageable streams: a low-volume, solid cake and a clean liquid filtrate, drastically reducing waste volume or recovering valuable product.

The Core Working Principle: From Slurry to Cake

The operation of a filter press is a sequential batch process. Each cycle follows a set of distinct phases to achieve separation.

The Fill Cycle

A pump pushes the slurry into the chambers of the filter press. It's crucial that the chambers are filled evenly to ensure consistent cake formation on all filter plates.

Solid/Liquid Separation

As pressure builds, the liquid component of the slurry is forced through the filter cloth. This cloth is the critical medium that traps the solid particles but allows the clean filtrate to pass.

Cake Formation

The trapped solids accumulate on the surface of the filter cloth. Over the course of the cycle, these solids build upon each other, forming a dense, dewatered puck known as the filter cake.

Cycle Completion

The cycle continues until the chambers are completely packed with solids and the flow of filtrate slows to a trickle. At this point, the press is full, the cycle is complete, and the solid cakes are ready for discharge.

Anatomy of a Filter Press

A filter press is a mechanically simple but powerful machine built from four essential components.

The Frame

The frame is the structural backbone of the machine. It holds the filter plates together under immense pressure during the filtration cycle and must be robust enough to withstand these forces.

The Filter Plates

These are the core components that create the series of chambers within the press. When pressed together, they form the voids where the slurry is pumped and the filter cake is formed.

The Filter Cloth

This is arguably the most critical component for operational success. The filter cloth is a specialized fabric fitted over each filter plate that performs the actual separation of solids from the liquid.

The Manifold

The manifold consists of the external piping and valves. It controls the flow of slurry into the press and directs the exiting clean filtrate away from the machine for collection or disposal.

Understanding the Trade-offs

While highly effective, the filter press is not a universal solution. Understanding its operational model is key to its proper application.

Batch vs. Continuous Operation

A filter press is a batch process machine. This means it must stop a cycle to discharge the cake before starting the next one. This downtime must be factored into overall process throughput calculations.

Slurry Consistency is Key

The performance of a filter press is highly dependent on the characteristics of the slurry being processed. Factors like particle size, distribution, and concentration directly impact filtration speed and final cake moisture.

Consumables and Maintenance

The filter cloths are a consumable item. They wear out over time and require periodic replacement, representing an ongoing operational cost. The high pressures also necessitate routine mechanical maintenance.

How to Apply This to Your Goal

The function of a filter press can be leveraged to achieve several distinct industrial objectives.

- If your primary focus is waste volume reduction: The press excels at converting large volumes of liquid sludge into a compact, solid cake, which dramatically cuts handling and disposal costs.

- If your primary focus is product recovery: The process efficiently separates a valuable solid product from a liquid stream, allowing you to harvest the cake for further processing.

- If your primary focus is water reclamation: The machine produces a high-quality filtrate that is often clean enough to be reused within the plant or safely discharged, reducing water consumption.

Ultimately, the filter press provides a robust and reliable method for achieving high-efficiency solid-liquid separation in demanding industrial environments.

Summary Table:

| Function | Key Benefit | Ideal For |

|---|---|---|

| Dewatering Slurry | Reduces waste volume & disposal costs | Wastewater treatment, mining |

| Solid Product Recovery | Harvests valuable solids from liquid streams | Chemical, pharmaceutical industries |

| Filtrate Reclamation | Produces clean water for reuse or discharge | Environmental compliance, water recycling |

Need a reliable solution for sludge dewatering or product recovery? KINTEK specializes in high-performance lab equipment and consumables, including industrial filtration systems tailored to your laboratory and process needs. Our filter press solutions help you reduce waste, recover valuable materials, and improve operational efficiency. Contact us today to discuss how we can support your specific application!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Warm Isostatic Press for Solid State Battery Research

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis