At its core, hardening is a controlled heat treatment process designed to dramatically increase the hardness and strength of a metal, most commonly steel. It involves heating the metal to a specific, very high temperature, holding it there, and then cooling it down with extreme speed. This rapid cooling, known as quenching, freezes the metal's internal structure in a strong but stressed state.

The essential goal of hardening is to trap a specific high-temperature crystal structure within the metal by cooling it too quickly for it to return to its softer, natural form. This process trades the metal's natural flexibility for exceptional hardness and wear resistance.

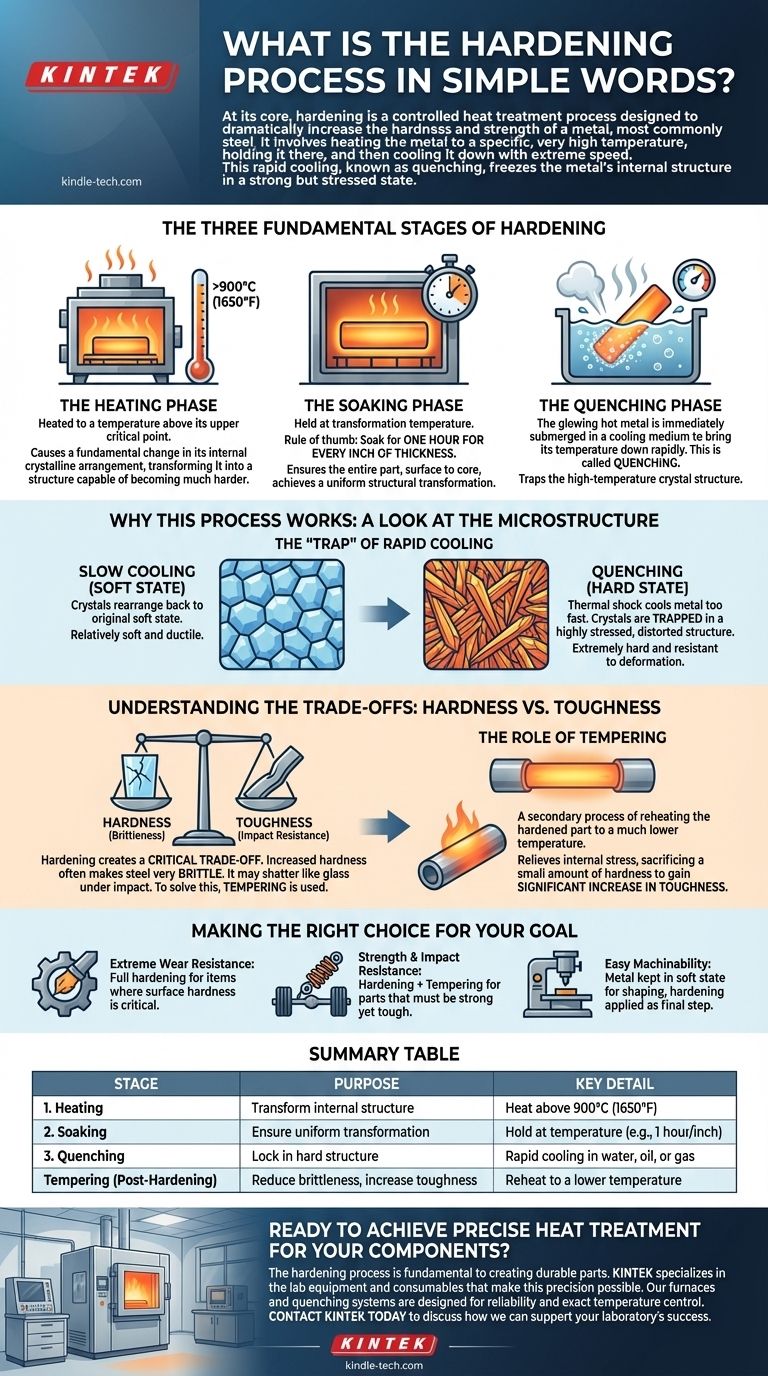

The Three Fundamental Stages of Hardening

The hardening process, whether in a modern vacuum furnace or a traditional forge, follows three distinct and critical stages. Each step plays a precise role in transforming the metal's internal properties.

Stage 1: The Heating Phase

First, the metal is heated in a furnace to a temperature above its upper critical point, often exceeding 900°C (1650°F).

Heating to this temperature doesn't melt the metal. Instead, it causes a fundamental change in its internal crystalline arrangement, transforming it into a structure that is capable of becoming much harder.

Stage 2: The Soaking Phase

Once the transformation temperature is reached, the metal is "soaked" by holding it at that temperature.

A common rule of thumb is to soak the material for one hour for every inch of its thickness. This ensures the entire part, from its surface to its core, has achieved a complete and uniform structural transformation.

Stage 3: The Quenching Phase

This is the most dramatic step. The glowing hot metal is removed from the furnace and immediately submerged in a cooling medium to bring its temperature down rapidly.

This rapid cooling is called quenching. Common quenching mediums include water, brine (salt water), oil, or even high-pressure inert gas like nitrogen, depending on the type of steel and desired outcome.

Why This Process Works: A Look at the Microstructure

The magic of hardening happens at a microscopic level. It's an intentional manipulation of the metal's crystalline lattice structure.

The Soft State vs. The Hard State

In its normal, room-temperature state, steel has a relatively soft and ductile crystalline structure. When heated past its critical point, it reorganizes into a different, more compact structure.

If the steel were allowed to cool slowly, the crystals would have time to rearrange themselves back into their original soft state.

The "Trap" of Rapid Cooling

Quenching is a thermal shock. It cools the metal so fast that the crystals do not have time to rearrange back to their soft form.

Instead, they are trapped in a highly stressed, distorted, and needle-like structure. This new, locked-in structure is extremely hard and resistant to deformation, which is what we perceive as increased material hardness.

Understanding the Trade-offs: Hardness vs. Toughness

Hardening is not a universal improvement. The significant increase in hardness comes at a cost, creating a critical trade-off that engineers must manage.

The Brittleness Problem

An extremely hardened piece of steel is often very brittle. While it can resist scratches and wear, it may shatter like glass if subjected to a sharp impact.

For many applications, this level of brittleness is unacceptable, as components need to absorb shock without failing catastrophically.

The Role of Tempering

To solve this, a secondary process called tempering is almost always performed after hardening.

Tempering involves reheating the hardened part to a much lower temperature. This process relieves some of the internal stress, sacrificing a small amount of hardness to gain a significant increase in toughness (resistance to fracture).

Making the Right Choice for Your Goal

Hardening is a foundational process used to engineer a metal's properties for a specific job. The approach depends entirely on the component's final application.

- If your primary focus is extreme wear resistance: A full hardening process is used for items like cutting tools, ball bearings, and gears, where surface hardness is the most critical property.

- If your primary focus is strength and impact resistance: A combination of hardening followed by tempering is essential for parts like axles, springs, and structural bolts that must be strong yet tough enough to bend without breaking.

- If your primary focus is easy machinability: The metal is kept in its softer, un-hardened state for processes like milling and shaping, with hardening applied only as a final step.

Ultimately, hardening is a precise metallurgical tool used to deliberately lock in a less stable internal structure to achieve a superior level of performance.

Summary Table:

| Stage | Purpose | Key Detail |

|---|---|---|

| 1. Heating | Transform internal structure | Heat above 900°C (1650°F) |

| 2. Soaking | Ensure uniform transformation | Hold at temperature (e.g., 1 hour per inch of thickness) |

| 3. Quenching | Lock in hard structure | Rapid cooling in water, oil, or gas |

| Tempering (Post-Hardening) | Reduce brittleness, increase toughness | Reheat to a lower temperature |

Ready to achieve precise heat treatment for your components?

The hardening process is fundamental to creating durable parts, from cutting tools to structural springs. KINTEK specializes in the lab equipment and consumables that make this precision possible. Our furnaces and quenching systems are designed for reliability and exact temperature control, ensuring your materials meet the highest standards of hardness and toughness.

Let our experts help you select the right equipment for your specific hardening and tempering needs. Contact KINTEK today to discuss how we can support your laboratory's success.

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- Vertical Laboratory Tube Furnace

People Also Ask

- What kind of energy does pyrolysis generate? Converting Waste into Valuable Fuels

- What is a pyrolysis furnace? A Tool for Converting Waste into Valuable Resources

- What is vacuum furnace heat treatment? Achieve Superior, Contamination-Free Metal Strengthening

- What is a high temperature furnace used for? A Guide to Material Transformation

- What is the necessity of achieving a high vacuum level of 10^-5 mbar? Ensure Purity in EHEAs Melting.

- What is the primary use of furnace in the chemical industry? Master Thermal Treatment for Material Transformation

- What does a vacuum furnace do? Achieve High-Purity Heat Treatment for Superior Components

- How does a vacuum drying oven benefit Al2O3-TiCN/Co-Ni slurry processing? Protect Material Integrity & Purity