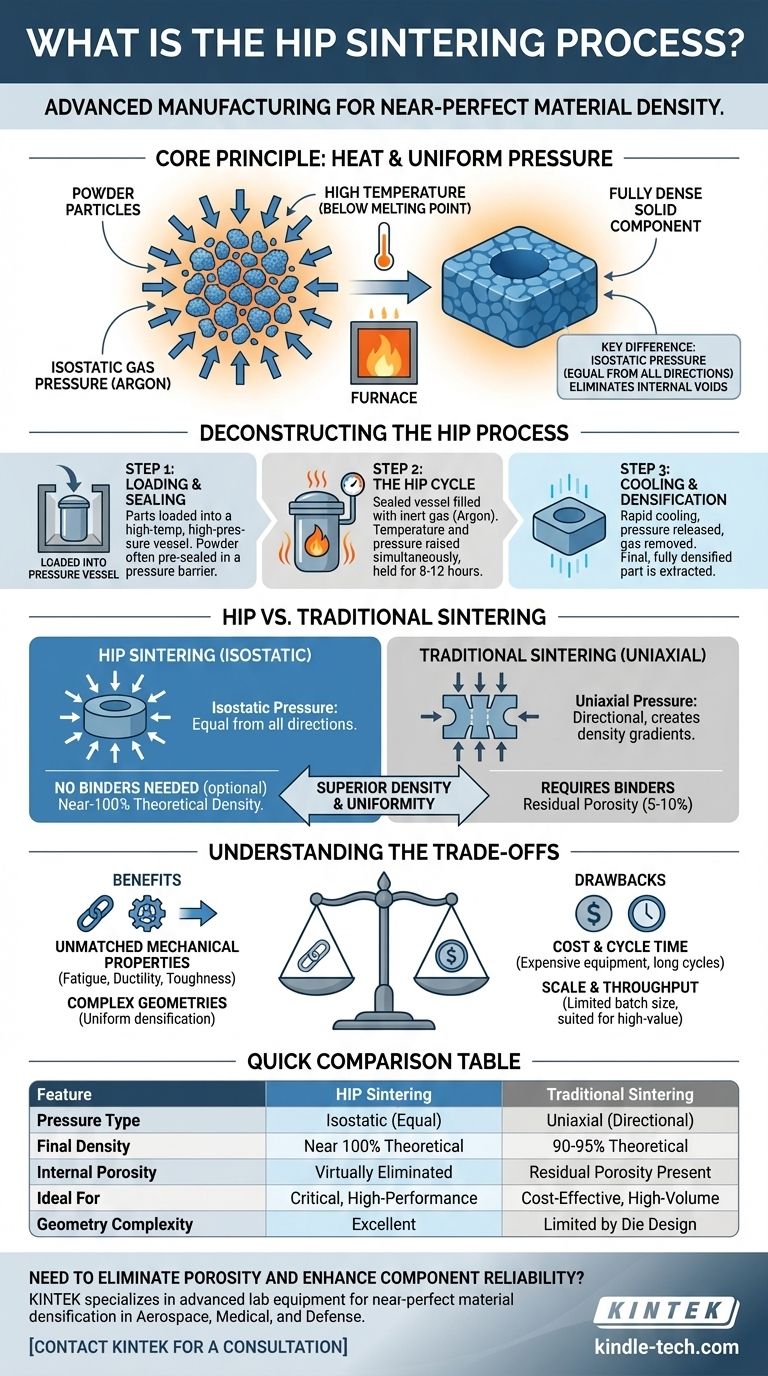

At its core, HIP Sintering is an advanced manufacturing process that uses a combination of high temperature and uniform, high-pressure gas to transform metal or ceramic powders into a fully dense, solid component. Unlike traditional methods that use mechanical presses, Hot Isostatic Pressing (HIP) applies pressure equally from all directions, effectively squeezing out internal voids and creating a part with superior strength and reliability.

The fundamental difference between HIP Sintering and traditional methods is the application of pressure. By using an inert gas to apply uniform (isostatic) pressure, the HIP process eliminates internal porosity far more effectively than the directional force of a mechanical press, resulting in materials that approach 100% of their theoretical density.

Deconstructing the HIP Sintering Process

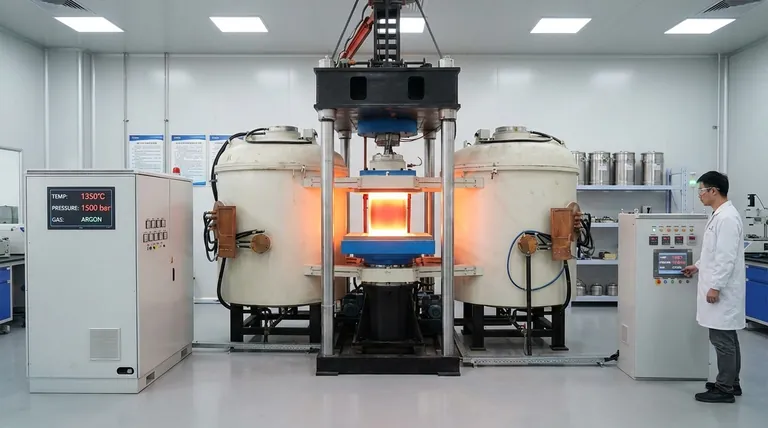

HIP Sintering is a method of densification. The process takes place inside a specialized piece of equipment that is both a high-temperature furnace and a high-pressure vessel.

The Core Principle: Heat and Uniform Pressure

The goal is to heat the material to a point where its atoms can move and bond, but below its melting point. Simultaneously, immense pressure is applied to force the individual powder particles to fuse together, eliminating the gaps between them.

Step 1: Loading and Sealing

Parts are first loaded into the furnace chamber. In many cases, the powder is pre-formed and sealed within a canister or mold that acts as a pressure barrier. This assembly is then placed inside the main pressure vessel.

Step 2: The HIP Cycle

The vessel is sealed, and an inert gas, typically argon, is pumped in. The temperature and pressure are then raised simultaneously according to a precise profile. This condition is held for a set duration, often lasting from 8 to 12 hours, allowing heat and pressure to fully penetrate the material.

Step 3: Cooling and Densification

After the holding period, the component is cooled, sometimes rapidly to achieve specific material properties in a process similar to quenching. The pressure is released, the recycled gas is removed, and the final, fully densified part is taken out.

How HIP Differs from Traditional Sintering

While both processes aim to create a solid part from powder, the method and results are significantly different. Understanding this distinction is key to knowing when to use HIP.

The Pressure Problem: Isostatic vs. Uniaxial

Traditional sintering often involves pressing powder into a "green part" using a mechanical die. This pressure is uniaxial (applied along one axis). This can leave density gradients and internal voids, as the force isn't transmitted perfectly throughout the part.

HIP, by contrast, uses gas to apply isostatic pressure, meaning it is equal in all directions. This hydrostatic force is incredibly effective at collapsing internal pores uniformly, regardless of the part's geometric complexity.

The Role of Binders and "Green Parts"

Traditional sintering typically requires a bonding agent (like wax or polymer) to hold the powder together in a preliminary "green part." This binder must be burned off during the heating cycle, which can sometimes introduce contamination or porosity.

HIP can consolidate powder directly without the need for these binders, leading to a purer final material. It can also be used as a secondary step to densify a part that has already been sintered through traditional means.

The Result: Superior Density

The primary outcome and main advantage of HIP is its ability to produce parts with near-100% theoretical density. Traditional sintering often results in parts with residual porosity (typically 5-10%), which can act as stress points and potential failure sites.

Understanding the Trade-offs

HIP is a high-performance process, and its use involves balancing significant benefits against practical constraints.

Benefit: Unmatched Mechanical Properties

By eliminating internal defects, HIP dramatically improves a material's mechanical properties, such as fatigue life, ductility, and fracture toughness. This is non-negotiable for critical components.

Benefit: Manufacturing Complex Geometries

Because pressure is applied by a gas, it conforms perfectly to any shape. This allows for the production of highly complex parts that would be difficult or impossible to densify uniformly with a mechanical press.

Drawback: Cost and Cycle Time

HIP equipment is expensive, and the process cycles are very long (often 8-12 hours or more). This makes it a more costly process on a per-part basis compared to high-volume traditional sintering.

Drawback: Scale and Throughput

The size of the pressure vessel limits the batch size. While large HIP units exist, the process is generally better suited for high-value, lower-volume production rather than mass-produced consumer parts.

Making the Right Choice for Your Goal

Deciding whether to use HIP Sintering depends entirely on the performance requirements and value of the final component.

- If your primary focus is critical performance and reliability: Choose HIP for applications in aerospace, medical implants, or defense where material failure is not an option.

- If your primary focus is producing parts with complex internal shapes: Use HIP to ensure uniform density and properties throughout intricate geometries.

- If your primary focus is cost-effective, high-volume production of non-critical parts: Traditional sintering methods are likely more suitable and economical.

Ultimately, you are selecting a process that guarantees the highest possible material integrity by trading longer cycle times and higher costs for near-perfect densification.

Summary Table:

| Feature | HIP Sintering | Traditional Sintering |

|---|---|---|

| Pressure Type | Isostatic (equal from all directions) | Uniaxial (directional) |

| Final Density | Near 100% theoretical density | Typically 90-95% theoretical density |

| Internal Porosity | Virtually eliminated | Residual porosity present |

| Ideal For | Critical, high-performance components (aerospace, medical) | Cost-effective, high-volume production |

| Geometry Complexity | Excellent for complex shapes | Limited by die design |

Need to Eliminate Porosity and Enhance Component Reliability?

If you are developing high-performance parts for the aerospace, medical, or defense industries where material failure is not an option, the HIP sintering process is your solution. KINTEK specializes in providing the advanced lab equipment and consumables needed to achieve near-perfect material densification.

Our expertise helps you produce components with superior strength, fatigue life, and reliability. Contact us today to discuss how our solutions can meet your laboratory's specific needs for critical performance and complex geometries.

Contact KINTEK for a Consultation

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- 1400℃ Laboratory Quartz Tube Furnace with Alumina Tube Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What does bond strength depend on in braze welding? Master the 3 Keys to a Strong Joint

- Can you get an electrical arc in vacuum? How High Voltage Creates Plasma in a Void

- What is the effect of increasing the pressure during sintering? Achieve Maximum Density and Superior Performance

- Why are brazed joints subjected to fatigue failure? Understanding the Critical Factors for Long-Lasting Joints

- What are the disadvantages of hot pressing? Key Limitations for Your Manufacturing Process