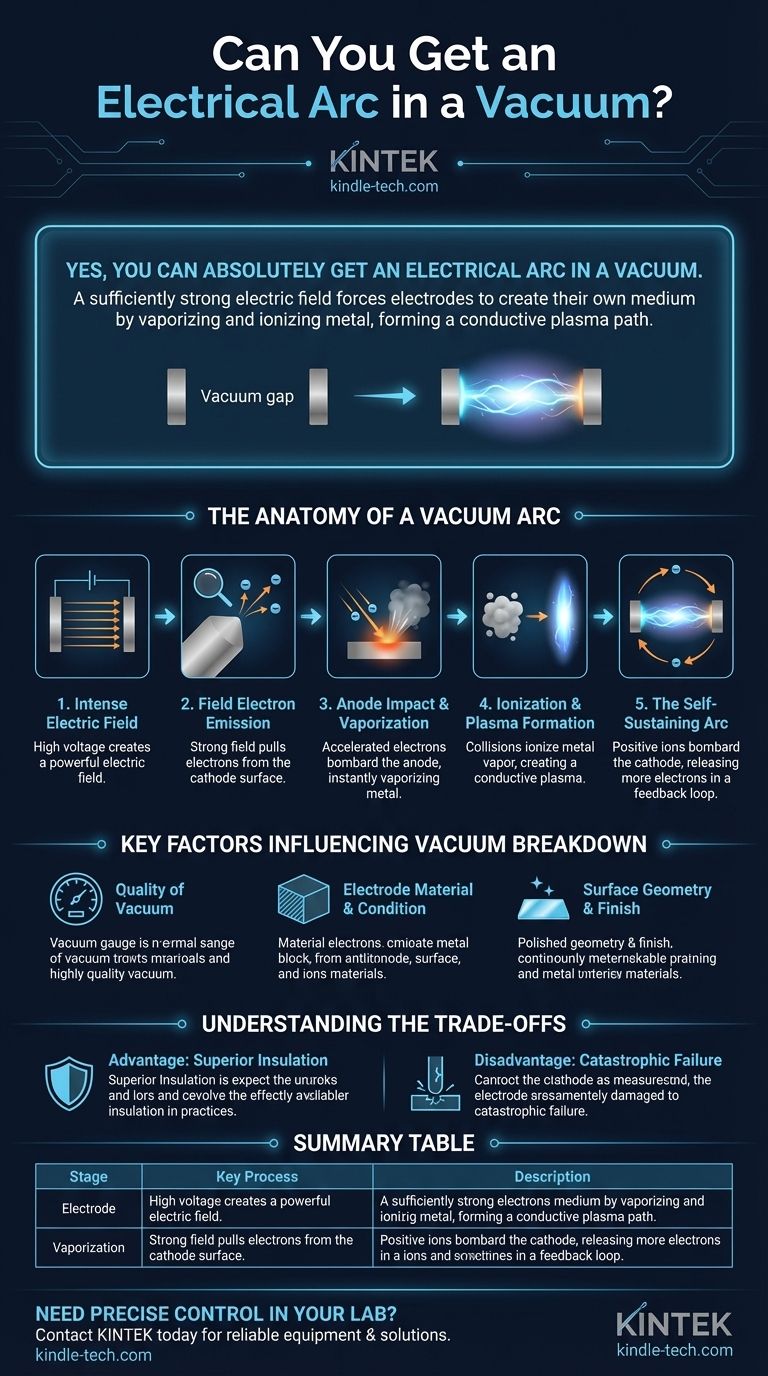

Yes, you can absolutely get an electrical arc in a vacuum. While a vacuum is an exceptional electrical insulator, it is not perfect. Under high voltage conditions, an arc can form not by breaking down a gas like air, but by vaporizing and ionizing the metal from the electrodes themselves, creating a conductive plasma path.

The core misunderstanding is thinking an arc requires a pre-existing medium like air. In reality, a sufficiently strong electric field in a vacuum can force the electrodes to create their own medium, leading to a violent and self-sustaining plasma discharge made of metal vapor.

The Anatomy of a Vacuum Arc

An electrical arc in a vacuum doesn't happen instantaneously. It's a cascading failure with several distinct steps that occur in microseconds.

Step 1: The Intense Electric Field

Everything begins with a high voltage potential between two conductive electrodes separated by a vacuum gap. This creates a powerful electric field, measured in volts per meter. The strength of this field is the primary driver of the entire process.

Step 2: Field Electron Emission

Even without heat, an extremely strong electric field can literally pull electrons directly out of the surface of the negative electrode (cathode). This quantum mechanical process is known as field electron emission. Microscopic sharp points on the electrode surface concentrate the electric field, making these spots the most likely sources of emission.

Step 3: Anode Impact and Vaporization

These emitted electrons accelerate across the vacuum gap at tremendous speeds, slamming into the positive electrode (anode). This focused bombardment of energy heats a microscopic spot on the anode to thousands of degrees, causing the electrode material itself to instantly vaporize.

Step 4: Ionization and Plasma Formation

A small cloud of neutral metal vapor now exists in the vacuum gap. The continuous stream of electrons from the cathode collides with these metal atoms, knocking off their electrons. This creates positive metal ions and more free electrons, transforming the vapor cloud into a plasma—a superheated, electrically conductive gas.

Step 5: The Self-Sustaining Arc

This newly formed plasma provides an almost perfect conduction path. The positive metal ions are accelerated back towards the cathode, striking it and causing even more electrons to be released through intense localized heating. This creates a self-sustaining feedback loop, resulting in a stable, high-current electrical arc.

Key Factors Influencing Vacuum Breakdown

Whether an arc forms depends on a delicate balance of conditions. Engineers who design high-voltage vacuum equipment obsess over these factors to prevent failure.

The Quality of the Vacuum

A "harder" vacuum (lower pressure with fewer stray gas molecules) has a much higher insulating strength than a "soft" vacuum. With more stray molecules present, it becomes easier to ionize them and start an arc at a lower voltage.

Electrode Material and Condition

The type of metal used for the electrodes is critical. Materials with lower work functions (less energy required to free an electron) and lower vaporization points will initiate an arc more easily. Impurities or absorbed gases on the electrode surface can also significantly lower the breakdown voltage.

Surface Geometry and Finish

This is arguably the most important factor in practical applications. Any microscopic sharp point or jagged edge on the electrode surface dramatically concentrates the electric field. This is why components for high-voltage vacuum use are often electropolished to a mirror finish to remove these potential arc-initiation sites.

Understanding the Trade-offs

The dual nature of a vacuum—being both a superior insulator and a potential conductor—creates a set of critical trade-offs in engineering.

The Advantage: Superior Insulation

For a given distance, a clean, hard vacuum can insulate against a far higher voltage than air or even oil. This allows for the design of more compact high-voltage components, which is essential in applications like X-ray tubes, particle accelerators, and satellite systems.

The Disadvantage: Catastrophic Failure

While breakdown is less likely, when a vacuum arc does occur, it is extremely destructive. The arc's current is concentrated into tiny "cathode spots" that are hotter than the surface of the sun, causing significant erosion and damage to the electrode surfaces. This damage creates more surface imperfections, making future arcs even more likely.

The Application: Controlled Arcs

This same phenomenon can be harnessed for industrial benefit. Vacuum interrupters, used in electrical grid substations, intentionally create and extinguish a vacuum arc to safely switch massive currents. The arc's plasma helps conduct the current, and because there is so little material in the vacuum, the plasma dissipates almost instantly when the current stops, safely interrupting the circuit.

Making the Right Choice for Your Goal

How you approach this phenomenon depends entirely on whether you see it as a problem to be solved or a tool to be used.

- If your primary focus is preventing arcing (High-Voltage Design): Prioritize smooth electrode surfaces, choose materials with high work functions, maintain the hardest vacuum possible, and maximize the gap distance.

- If your primary focus is utilizing arcing (Industrial Processes): Focus on electrode materials that can withstand arc erosion and design a magnetic field to control the arc's position and prevent it from dwelling in one spot.

- If your primary focus is fundamental understanding: Remember that the arc is not a failure of the vacuum itself, but a process where the electric field forces the electrodes to become the fuel for their own discharge.

Ultimately, understanding the mechanism of a vacuum arc is the key to both preventing electrical failure and harnessing its power for innovation.

Summary Table:

| Stage | Key Process | Description |

|---|---|---|

| 1. Initiation | Field Electron Emission | A strong electric field pulls electrons from the cathode's surface. |

| 2. Vaporization | Anode Bombardment | Accelerated electrons strike the anode, vaporizing metal. |

| 3. Conduction | Plasma Formation | Metal vapor is ionized, creating a conductive plasma path. |

| 4. Sustenance | Feedback Loop | Positive ions bombard the cathode, releasing more electrons and sustaining the arc. |

Need precise control over electrical processes in your lab?

The science of vacuum arcs is critical for developing and operating advanced equipment, from high-voltage systems to material processing tools. At KINTEK, we specialize in providing the reliable lab equipment and consumables that support this kind of cutting-edge research and development.

Whether you are designing high-voltage components or utilizing plasma processes, having the right tools is essential for success and safety. Let KINTEK be your partner in innovation.

Contact our experts today to discuss how our solutions can meet your specific laboratory needs.

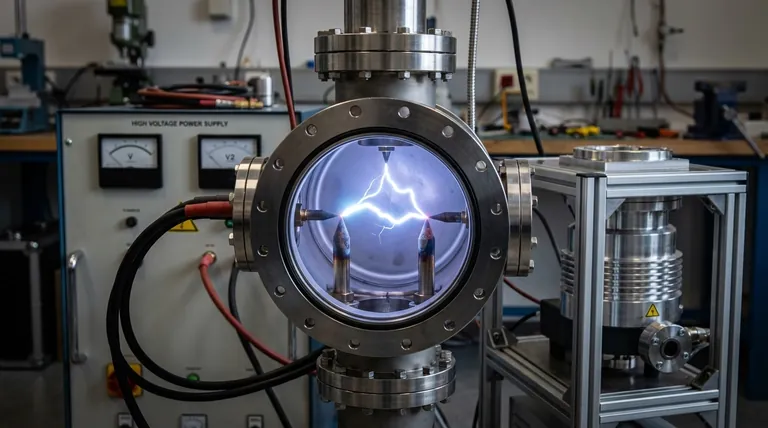

Visual Guide

Related Products

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What role do laboratory high-temperature isothermal annealing furnaces play? Analyze Material Recovery After Irradiation

- What are the advantages of using a laboratory vacuum drying oven for SRB regeneration? Preserve Biological Viability

- Why is a vacuum annealing furnace required for Inconel 713LC & 738? Ensure Peak Superalloy Performance

- Why is stainless steel hard to braze? Overcome the Chromium Oxide Barrier for Strong Joints

- What is the process of sinter machine? A Guide to Powder Metallurgy and Thermal Bonding

- What are the advantages of powder sintering? Unlock Superior Strength, Conductivity & Translucency

- What are the process advantages of using a vacuum oven for RGO/PMMA nanocomposites? Enhance Density and Integrity

- What is the preheat temperature for cast iron brazing? Achieve a Strong, Crack-Free Repair