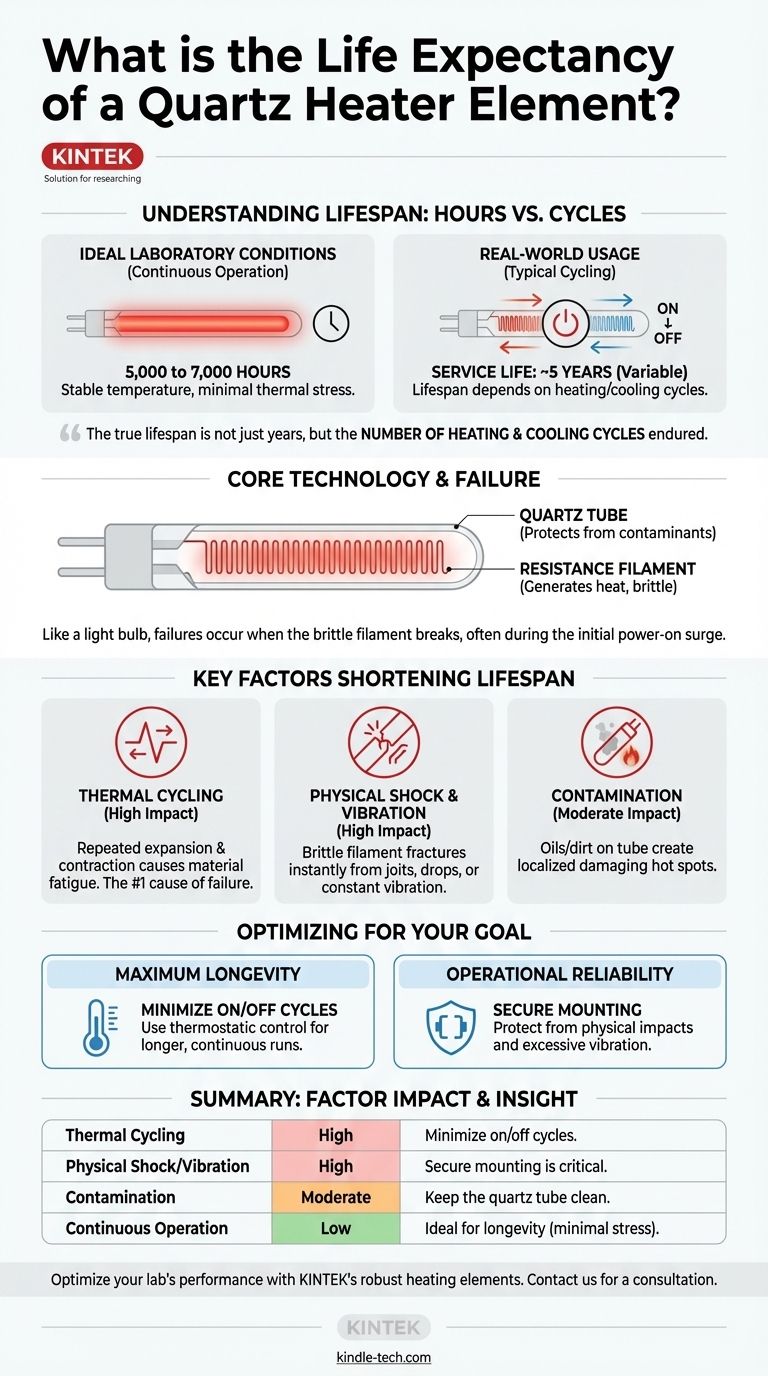

Under ideal laboratory conditions, a quartz heater element has an estimated operational life of 5,000 to 7,000 hours. For typical usage patterns, this often translates into a service life of at least five years, but this figure is highly dependent on how the heater is used.

The true lifespan of a quartz heater element is not measured in years, but in the number of heating and cooling cycles it endures. Understanding the impact of its operational environment is the key to maximizing its longevity.

Deconstructing the "5,000-Hour" Benchmark

The often-quoted figure of 5,000-7,000 hours represents the element's lifespan under continuous, non-stop operation. This is an important distinction for understanding its real-world durability.

The Ideal Scenario: Continuous Operation

The 5,000-hour rating assumes the element is turned on and left on. In this state, the internal filament reaches a stable temperature and experiences minimal thermal stress, which is the expansion and contraction of materials due to temperature changes.

This is the least demanding scenario for the element, allowing it to function for the maximum possible duration.

Translating Hours into Real-World Use

In practice, heaters are turned on and off frequently. This cycling is the primary factor that shortens an element's life.

For example, 5,000 hours could mean over two years of use if a heater runs for 6 hours every single day. However, if that same heater is switched on and off a dozen times a day, its lifespan could be significantly reduced even if the total "on" time is lower.

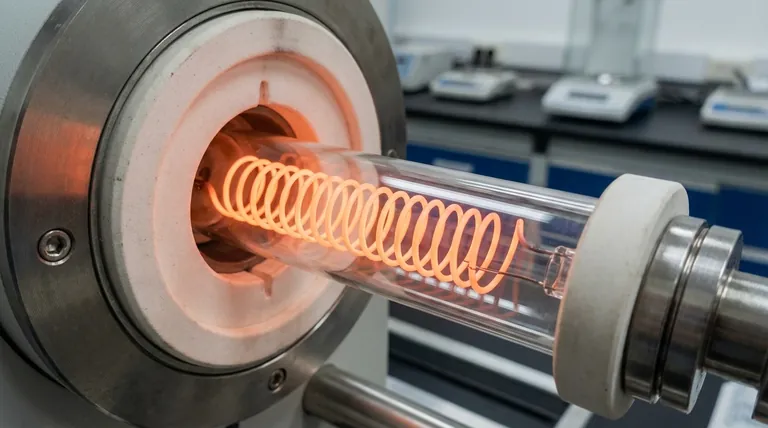

The Core Technology: A Robust Filament

At its heart, a quartz element contains a resistance wire filament, similar in principle to an incandescent light bulb. The quartz tube serves to protect this delicate filament from air, contaminants, and physical touch, allowing it to operate at very high temperatures efficiently.

Like a light bulb, the vast majority of failures occur when the filament finally breaks, most often during the initial power-on surge.

Key Factors That Shorten an Element's Lifespan

An element's longevity is rarely determined by its maximum hour rating. It is almost always dictated by external factors that cause premature failure.

The Primary Culprit: Thermal Cycling

Every time the element is turned on, the filament rapidly heats and expands. When turned off, it cools and contracts. This repeated expansion and contraction is the single greatest cause of wear, eventually leading to material fatigue and breakage.

Physical Shock and Vibration

The internal filament is brittle and susceptible to fracture. A sharp jolt, a drop, or even significant ongoing vibration can cause the filament to break instantly, regardless of its age or usage hours.

Contamination on the Quartz Tube

While the quartz tube is highly resilient, allowing contaminants like oils from fingerprints to burn onto its surface can create hot spots. These localized areas of intense heat can stress the tube and, in rare cases, contribute to a shorter lifespan of the internal filament.

Making the Right Choice for Your Goal

Understanding how a quartz element functions allows you to actively manage its lifespan and reliability based on your specific application.

- If your primary focus is maximum longevity: Minimize the number of on/off cycles. It is often better to let the heater run for a longer, continuous period under thermostatic control than to switch it on and off manually to manage temperature.

- If your primary focus is operational reliability: Ensure the heater is mounted securely in a low-traffic area where it is protected from physical bumps, impacts, and excessive vibration.

By shifting your focus from a simple hour rating to the operational stresses it endures, you gain direct control over the element's effective service life.

Summary Table:

| Factor | Impact on Lifespan | Key Insight |

|---|---|---|

| Thermal Cycling | High | The primary cause of failure. Minimize on/off cycles. |

| Physical Shock/Vibration | High | Can cause instant filament breakage. Secure mounting is critical. |

| Contamination | Moderate | Oils or dirt on the quartz tube can create damaging hot spots. |

| Continuous Operation | Low | Ideal for longevity; causes minimal thermal stress. |

Ensure your lab's heating processes are reliable and efficient. The longevity of your quartz heater elements is critical to your workflow. KINTEK specializes in high-quality lab equipment and consumables, including robust heating elements designed for demanding laboratory environments. Our experts can help you select the right heater for your application and provide guidance on best practices to maximize its service life.

Let's optimize your lab's performance together. Contact our team today for a consultation!

Visual Guide

Related Products

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Multi-zone Laboratory Tube Furnace

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

People Also Ask

- Why are quartz tubes preferred for chromium powder combustion? Superior Heat Resistance & Optical Clarity

- What happens when quartz is heated? A Guide to Its Critical Phase Transitions and Uses

- What is the function of quartz tubes and vacuum sealing systems? Secure Your High-Purity Solid Solution Synthesis

- What is the primary function of quartz tubes in halide electrolyte synthesis? Ensure Purity & Precise Stoichiometry

- What role does a quartz tube furnace play in hBN synthesis? Optimize Your Chemical Vapor Deposition Results