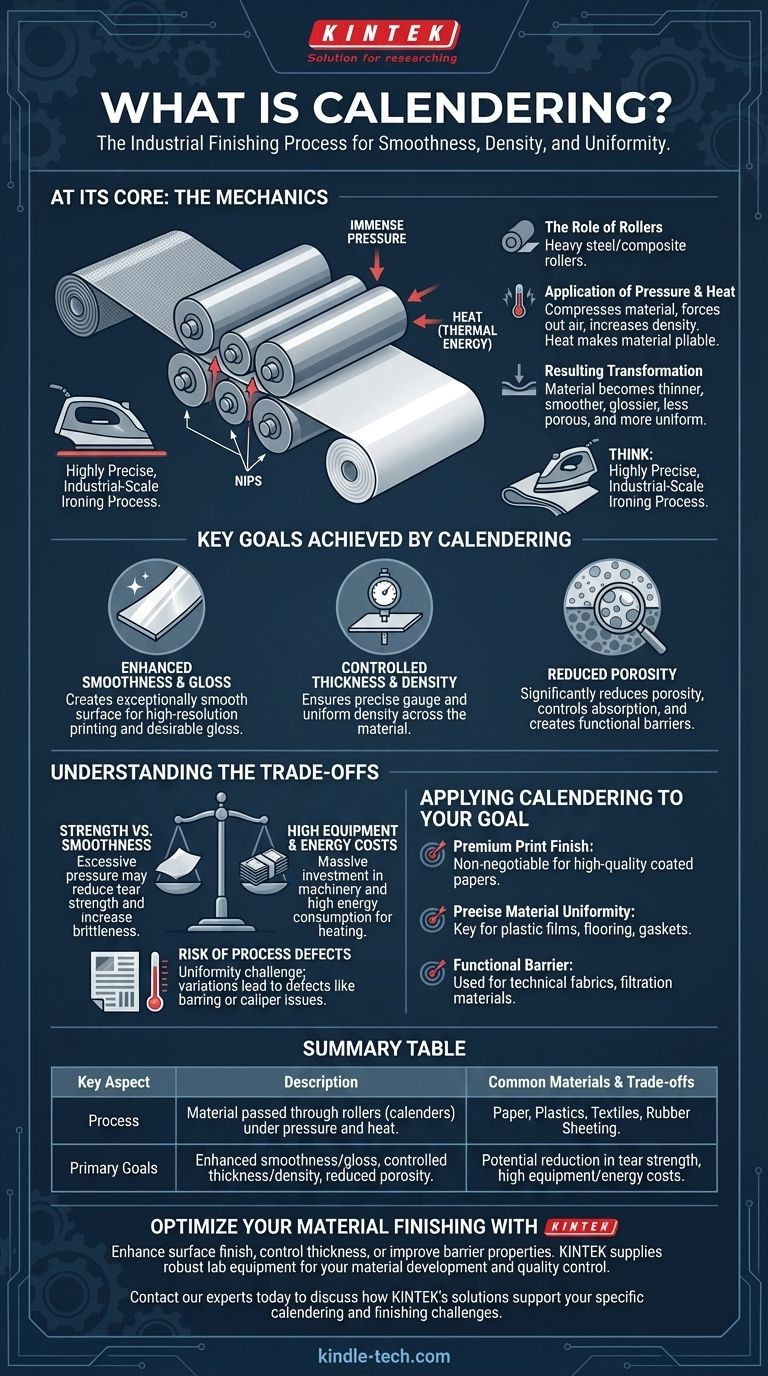

At its core, calendering is an industrial finishing process that uses a series of heavy rollers to smooth, compress, and control the thickness of a material. Most commonly applied to continuous sheets like paper, plastics, or textiles, the material is passed through the gaps—or "nips"—between these rollers, which apply immense pressure and often heat to alter its surface and physical properties.

Think of calendering as a highly precise, industrial-scale ironing process. Its primary purpose is not just to flatten a material, but to fundamentally change its surface finish, density, and uniformity by applying controlled pressure and heat.

How the Calendering Process Works

To understand the impact of calendering, you must first understand its core mechanics. The process is a combination of immense mechanical force and, frequently, thermal energy.

The Role of Rollers (Calenders)

The heart of the process is the calender itself—a stack of heavy, horizontally-aligned rollers made of steel or other hard composites. A sheet of material is fed through the nips between these rollers in a winding path.

The number, arrangement, and material of these rollers are precisely engineered to achieve a specific outcome on the final product.

The Application of Pressure and Heat

As the material passes through each nip, it is subjected to extreme pressure, which compresses it. This action forces out air, increases the material's density, and flattens its surface.

Many calendering processes also use heated rollers. The heat makes the material (especially polymers or paper fibers with moisture) more pliable, allowing it to be permanently reshaped for a smoother, glossier finish.

The Resulting Material Transformation

The combination of pressure and heat fundamentally alters the sheet. The surface becomes significantly smoother and often glossier. The material becomes thinner, more uniform in thickness, and less porous.

Key Goals Achieved by Calendering

Manufacturers use calendering to achieve specific, valuable improvements in a material's characteristics. The process is not merely cosmetic; it is a critical step for performance.

Enhanced Smoothness and Gloss

The primary goal for materials like high-quality paper is creating an exceptionally smooth surface. This reduces surface roughness, which is critical for high-resolution printing, resulting in sharper images and text. The process also imparts a desirable gloss or sheen.

Controlled Thickness and Density

For industrial materials like plastic films or rubber sheeting, precise gauge (thickness) control is paramount. Calendering compresses the material to a highly consistent thickness across its entire width and length, while also increasing its overall density.

Reduced Porosity

By compressing the material and squeezing out air pockets, calendering significantly reduces its porosity. For paper, this controls ink absorption. For technical textiles or films, it can create a barrier that is less permeable to air or liquids.

Understanding the Trade-offs

While powerful, calendering is a process of compromise. Optimizing for one property can negatively affect another, and the process itself has inherent challenges.

Strength vs. Smoothness

Excessive pressure can align fibers in paper too tightly or over-stress a polymer chain, potentially making the material more brittle and reducing its tear strength even as it becomes smoother. The engineering goal is to find the balance that meets product specifications.

High Equipment and Energy Costs

Calender stacks are massive, high-precision machines that represent a significant capital investment. Furthermore, heating the large steel rolls is an energy-intensive process, adding to the operational cost of manufacturing.

Risk of Process Defects

Maintaining perfectly uniform pressure and temperature across the entire width of a fast-moving sheet is a major engineering challenge. Any slight variation can lead to defects like barring (visual bands), blotchiness, or caliper variations that can ruin the product.

Applying Calendering to Your Goal

Choosing or specifying a calendered material requires understanding your primary objective. The process is tailored to achieve different end results.

- If your primary focus is a premium print finish: Calendering is non-negotiable for producing the smooth, glossy surface required for high-quality coated papers used in magazines and marketing materials.

- If your primary focus is precise material uniformity: Calendering is the key process for manufacturing plastic films, vinyl flooring, and gaskets where consistent thickness and density are critical for performance.

- If your primary focus is creating a functional barrier: The compression from calendering is used to reduce the porosity of technical fabrics and nonwovens for applications in filtration or protective apparel.

Ultimately, calendering is a fundamental tool for precisely controlling the final surface properties and physical structure of sheet materials.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process | Material passed through rollers (calenders) under pressure and heat. |

| Primary Goals | Enhanced smoothness/gloss, controlled thickness/density, reduced porosity. |

| Common Materials | Paper, plastics, textiles, rubber sheeting. |

| Key Trade-offs | Potential reduction in tear strength, high equipment/energy costs. |

Optimize Your Material Finishing Process with KINTEK

Are you looking to enhance the surface finish, control thickness, or improve the barrier properties of your materials? The precision and consistency offered by calendering are critical for high-performance results in industries from printing to technical textiles.

At KINTEK, we specialize in supplying robust and efficient lab equipment and consumables that support your material development and quality control processes. Whether you are researching new materials or ensuring production quality, our solutions are designed to meet the demanding needs of modern laboratories.

Let us help you achieve superior material properties. Contact our experts today to discuss how KINTEK's equipment can support your specific calendering and finishing challenges.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Manual Lab Heat Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- How much force can a hydraulic press exert? Understanding its immense power and design limits.

- How much pressure can a hydraulic press make? From 1 Ton to 75,000+ Tons of Force

- What is KBr disc method? A Complete Guide to IR Spectroscopy Sample Prep

- Why is the KBr plate used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- What is the purpose of KBr pellets? Unlock Clear FTIR Analysis of Solid Samples