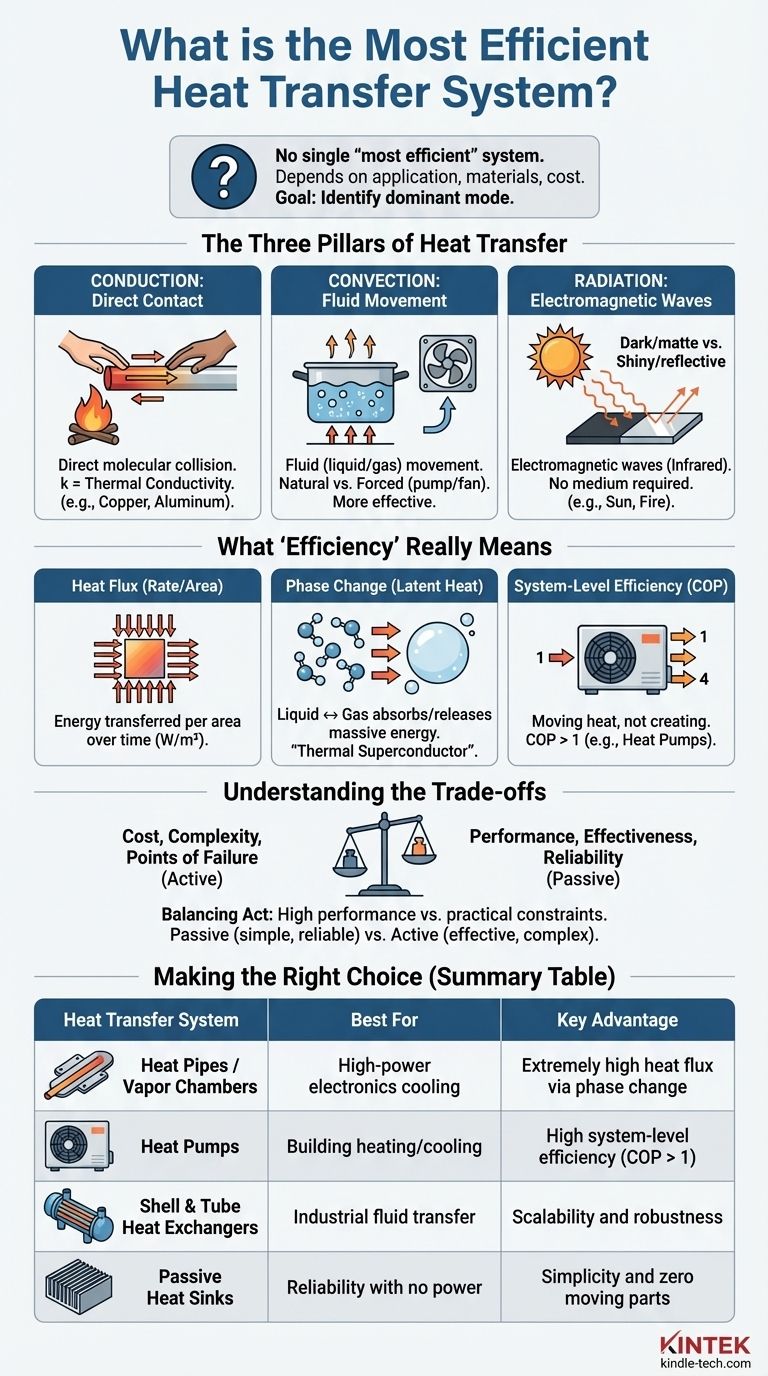

To be direct, there is no single "most efficient" heat transfer system. The efficiency of a system is entirely dependent on the specific application, the materials involved, the temperature difference, and the cost constraints. However, systems that utilize phase-change heat transfer, such as heat pipes or refrigeration cycles, often achieve the highest rates of heat transfer for their size because they leverage the immense energy absorbed or released when a substance changes state (e.g., from liquid to gas).

The search for the "most efficient" system is misleading. The real goal is to identify the dominant mode of heat transfer required for your specific problem—conduction, convection, or radiation—and select a system designed to maximize its effectiveness within your budget and physical constraints.

The Three Pillars of Heat Transfer

To understand efficiency, you must first understand the fundamental ways heat moves. Every heat transfer system is built upon one or more of these three mechanisms.

Conduction: Direct Contact

Conduction is heat transfer through direct molecular collision. Imagine holding a metal rod with one end in a fire; the heat travels up the rod to your hand.

This process is governed by a material's thermal conductivity (k). Materials like copper and aluminum are excellent conductors, while materials like wood or plastic are poor conductors (insulators).

Convection: Fluid Movement

Convection is heat transfer through the movement of a fluid (a liquid or gas). When you boil water, the hot water at the bottom rises, transferring heat to the cooler water at the top.

This can be natural convection (driven by density differences, like hot air rising) or forced convection (driven by a pump or fan), which is generally much more effective.

Radiation: Electromagnetic Waves

Radiation is heat transfer via electromagnetic waves, primarily in the infrared spectrum. It requires no medium to travel. This is how the sun warms the Earth or how you feel heat from a glowing campfire even from a distance.

Dark, matte surfaces are good at both absorbing and emitting radiation, while shiny, reflective surfaces are poor at both.

What "Efficiency" Really Means

The term "efficiency" can be misleading because it has different meanings depending on the context. In heat transfer, we often talk about effectiveness or rate, not just energy conversion.

Heat Flux: The True Measure of Rate

The most important metric is often heat flux—the amount of energy transferred per unit of area over time (measured in Watts per square meter). A system with high heat flux moves a lot of heat quickly in a small space.

The Power of Phase Change

The most effective way to achieve extremely high heat flux is through phase-change heat transfer. This is a special type of convection.

When a liquid boils into a gas, it absorbs a massive amount of energy called latent heat of vaporization without changing its temperature. Condensing that gas back into a liquid releases that same amount of energy. This is far more energy than can be transferred just by heating a liquid.

System-Level Efficiency (COP)

For systems like air conditioners and heat pumps, efficiency is measured by the Coefficient of Performance (COP).

This isn't about creating heat, but moving it. A COP of 4.0 means the system moves 4 units of heat energy for every 1 unit of electrical energy it consumes. This is why heat pumps can be over 100% efficient at heating compared to electric resistance heaters.

Understanding the Trade-offs

Choosing a system is always a balancing act. The theoretically "best" system is often impractical or too expensive for a given application.

Cost vs. Performance

Materials with the highest thermal conductivity, like diamond and silver, are prohibitively expensive for most uses. Copper and aluminum represent a practical compromise between excellent thermal performance and reasonable cost.

Simplicity vs. Effectiveness

Passive systems, like a simple heat sink relying on natural convection, have no moving parts and are extremely reliable. They are, however, far less effective than active systems.

An active system, like one using a pump to force liquid through a cooling block (forced convection), offers much higher performance but introduces complexity, cost, and additional points of failure (the pump, seals, etc.).

Operating Window

Phase-change systems like heat pipes are incredibly effective, acting like thermal "superconductors." However, they are designed to operate within a specific temperature range. Outside that range, their performance drops dramatically.

Making the Right Choice for Your Goal

Your choice depends entirely on what you are trying to accomplish. Define your primary goal, and the best path will become clear.

- If your primary focus is cooling high-power electronics: You need to manage high heat flux in a small area, making phase-change systems like heat pipes or vapor chambers ideal.

- If your primary focus is heating or cooling a building: You need high system-level efficiency over a wide range of conditions, making a heat pump (air-source or geothermal) the superior choice.

- If your primary focus is transferring heat between two fluids in an industrial process: The robust and scalable design of a shell and tube or plate heat exchanger is the industry standard.

- If your primary focus is maximum reliability with no power input: You need a passive system, making a properly sized heat sink using conduction and natural convection the correct choice.

Ultimately, the most efficient heat transfer system is the one that is correctly engineered for its specific task.

Summary Table:

| Heat Transfer System | Best For | Key Advantage |

|---|---|---|

| Heat Pipes / Vapor Chambers | High-power electronics cooling | Extremely high heat flux via phase change |

| Heat Pumps | Building heating/cooling | High system-level efficiency (COP > 1) |

| Shell & Tube Heat Exchangers | Industrial fluid transfer | Scalability and robustness |

| Passive Heat Sinks | Reliability with no power | Simplicity and zero moving parts |

Struggling to select the right heat transfer solution for your lab equipment? At KINTEK, we specialize in providing tailored lab equipment and consumables that optimize thermal management for your specific applications. Whether you need precise cooling for sensitive instruments or efficient heating for industrial processes, our experts can help you identify the most effective system to enhance performance, reliability, and cost-efficiency. Contact us today to discuss your project and discover how KINTEK can support your laboratory's unique needs!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Cylindrical Lab Electric Heating Press Mold for Laboratory Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Variable Speed Peristaltic Pump

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

People Also Ask

- What color diamonds are CVD? Understanding the Process from Brown Tint to Colorless Beauty

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition