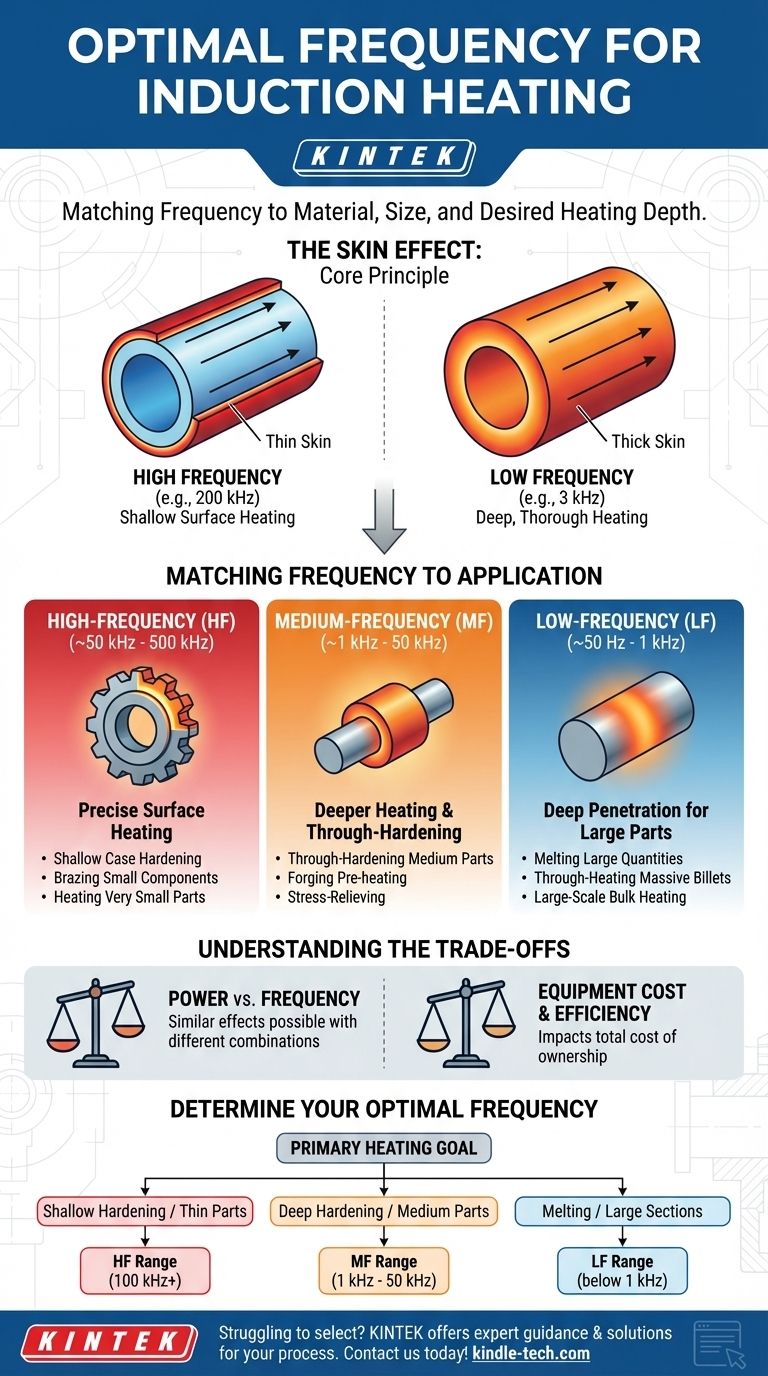

There is no single optimal frequency for induction heating. Instead, the ideal frequency is entirely determined by the material, the size of the part, and most importantly, the desired heating depth. Generally, high-frequency systems operate between 50 kHz and 500 kHz, but the correct choice is a careful balance of physics and process requirements.

The core principle to understand is this: Higher frequencies heat a shallower layer on the surface of a part, while lower frequencies penetrate more deeply. The "optimal" frequency is the one that concentrates the heat energy precisely where you need it for your specific application.

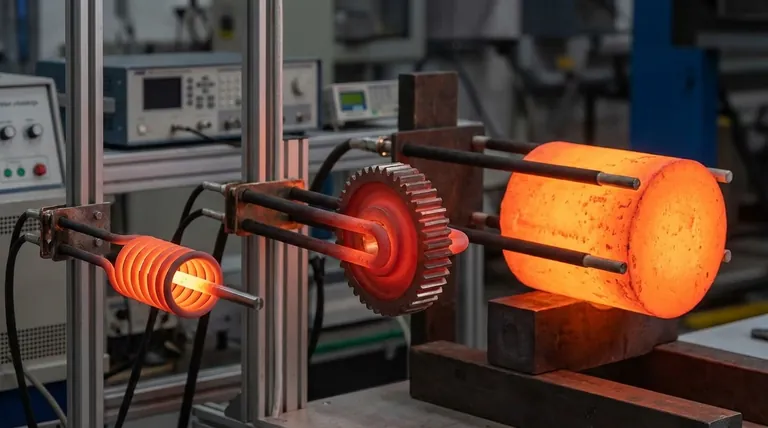

The Core Principle: The Skin Effect

The entire science of selecting an induction heating frequency revolves around a phenomenon known as the skin effect. Understanding this is critical to making an informed decision.

What is the Skin Effect?

When alternating current (AC) flows through a conductor, it doesn't use the entire cross-section uniformly. The current density is highest at the surface and decreases exponentially toward the center.

This means the heat generated by the current is also concentrated in this outer "skin."

How Frequency Controls Heating Depth

The thickness of this skin is directly controlled by the frequency of the alternating current. The relationship is simple and inverse:

- High Frequency (e.g., 200 kHz): Creates a very thin skin. This results in rapid, concentrated heating on the immediate surface of the part.

- Low Frequency (e.g., 3 kHz): Creates a much thicker skin. This allows heat to be generated deeper within the part, resulting in slower, more thorough heating.

Matching Frequency to Your Application

Different heating processes have fundamentally different requirements for heat placement, making frequency selection the primary variable.

High-Frequency (HF) Applications (~50 kHz - 500 kHz)

This range is ideal for applications requiring precise surface heating. The shallow heating depth is perfect for treating the outer layer of a part without affecting the core's properties.

Common uses include shallow case hardening, brazing small components, and heating very small parts quickly.

Medium-Frequency (MF) Applications (~1 kHz - 50 kHz)

Also known as the super-audio frequency (SAF) range, this is a versatile middle ground. It provides a deeper heating depth suitable for larger parts or applications that require more than just surface treatment.

This range is often used for through-hardening of medium-sized parts, pre-heating for forging, and stress-relieving.

Low-Frequency (LF) Applications (~50 Hz - 1 kHz)

Low frequencies are the solution for heating very large, thick parts where the energy must penetrate deep into the material's core.

The primary applications are melting large quantities of metal, through-heating massive billets for forging, and other large-scale bulk heating tasks.

Understanding the Trade-offs

The technically "perfect" frequency is not always the most practical or economical choice.

Power vs. Frequency

For some applications, a similar heating effect can be achieved with different combinations of power and frequency. For instance, a higher-power system at a medium frequency might achieve a similar result to a lower-power, high-frequency system if the goal is simply to get heat into a part.

Equipment Cost and Efficiency

The choice of frequency directly impacts the cost and complexity of the induction power supply and matching coil. You must consider the total cost of ownership, not just the theoretical optimum. The best frequency for your process may be the one provided by equipment that fits your budget.

How to Determine Your Optimal Frequency

Base your decision on the primary goal of your heating process.

- If your primary focus is shallow case hardening or heating very thin parts: Start your search in the high-frequency (HF) range (100 kHz+).

- If your primary focus is deep-case hardening or through-heating medium-sized parts: A medium-frequency (MF) system is the most likely solution (1 kHz - 50 kHz).

- If your primary focus is melting or heating very large, thick cross-sections: You must operate in the low-frequency (LF) range (below 1 kHz).

Ultimately, selecting the right frequency is about precisely controlling where and how deep you apply the heat.

Summary Table:

| Frequency Range | Heating Depth | Ideal Applications |

|---|---|---|

| High (50-500 kHz) | Shallow (Surface) | Shallow case hardening, brazing small parts |

| Medium (1-50 kHz) | Medium | Through-hardening, forging pre-heat |

| Low (50 Hz-1 kHz) | Deep (Bulk) | Melting, heating large billets |

Struggling to select the right frequency for your induction heating process? KINTEK specializes in laboratory equipment and consumables, offering expert guidance and tailored solutions for your specific material and application needs. Whether you're working with small components or large-scale projects, our team can help you optimize your heating process for maximum efficiency and performance. Contact us today to discuss your requirements and discover how KINTEK can enhance your lab's capabilities!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Anti-Cracking Press Mold for Lab Use

- Engineering Advanced Fine Ceramics Aluminum Oxide Al2O3 Heat Sink for Insulation

- Laboratory Test Sieves and Sieving Machines

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- What material is used for making heating element? Choose the Right Alloy for Your Application

- What is a silicon carbide heating element? Unlock Extreme Heat for Industrial Processes

- What is the maximum temperature for silicon carbide heating element? The Real Limit for Your High-Temp Furnace

- What are the uses of silicon carbide rod? The Ultimate Heating Solution for Extreme Temperatures

- What is silicon carbide rod heated to high temperature used as? A Premier Heating Element for Extreme Environments