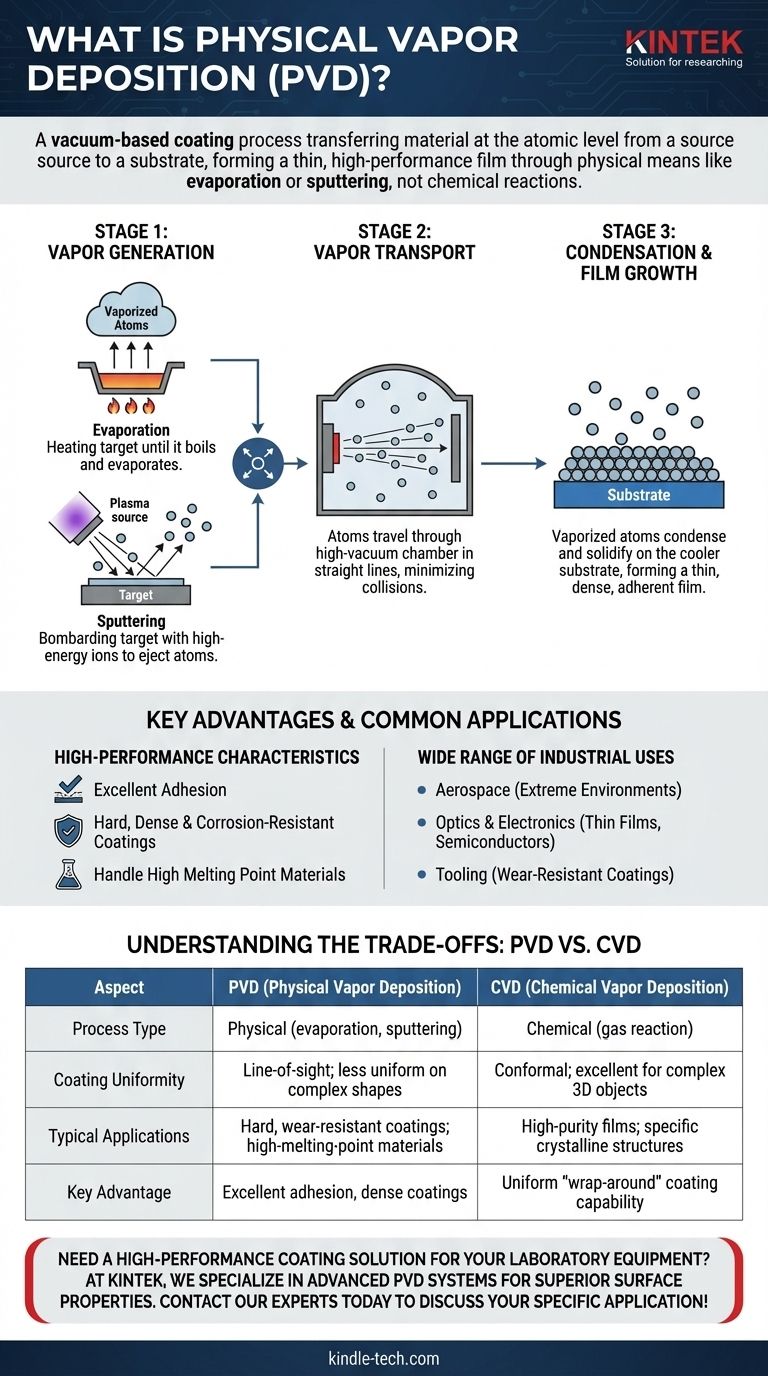

In essence, Physical Vapor Deposition (PVD) is a vacuum-based coating process that transfers material on an atomic level from a source to a substrate's surface. This method involves physically generating a vapor from a target material—through processes like evaporation or sputtering—which then travels through the vacuum and condenses onto the object, forming a very thin, high-performance film.

The central concept behind PVD is its purely physical nature. Unlike other methods, it does not rely on chemical reactions but instead uses physical force or high temperatures to create a vapor that solidifies as a durable, thin coating on a target surface.

The Core Principle: From Solid to Vapor to Film

Physical Vapor Deposition is a "line-of-sight" process that takes place within a high-vacuum chamber. The entire method can be broken down into three fundamental stages.

Stage 1: Vapor Generation

The first step is to convert the solid coating material (known as the "target") into a vapor. This is typically achieved in one of two ways.

Evaporation involves heating the target material in a vacuum until it boils and evaporates, releasing atoms that travel through the chamber.

Sputtering (referred to as "spraying" in some contexts) involves bombarding the target with high-energy ions, which physically knock atoms off the material's surface, ejecting them into the vacuum chamber.

Stage 2: Vapor Transport

Once the atoms are vaporized, they travel through the vacuum chamber. The vacuum is critical because it ensures there are minimal other gas particles for the vaporized atoms to collide with, allowing them to travel in a straight line directly to the substrate.

Stage 3: Condensation and Film Growth

When the vaporized atoms reach the cooler surface of the substrate (the object being coated), they condense and solidify. This builds up, layer by layer, to form a thin, dense, and highly adherent film. The final characteristics of this film depend on factors like the rate of deposition and the energy of the arriving atoms.

Key Advantages and Common Applications

PVD is chosen for its ability to produce coatings with specific, high-performance characteristics. Its physical nature makes it uniquely suited for certain materials and outcomes.

High-Performance Characteristics

PVD films are known for their excellent adhesion to the substrate. The process can also create exceptionally hard, dense, and corrosion-resistant coatings.

Versatility with Materials

A significant advantage of PVD is its ability to handle materials with very high melting points, which are difficult or impossible to process using other methods.

Wide Range of Industrial Uses

The benefits of PVD are applied across many industries. Common applications include:

- Aerospace: Applying dense, temperature-resistant coatings to components to withstand extreme environments.

- Optics & Electronics: Creating thin optical films for solar panels and coatings for semiconductors.

- Tooling: Adding hard, wear-resistant coatings to cutting tools and industrial components to extend their lifespan in harsh conditions.

Understanding the Trade-offs: PVD vs. CVD

To fully grasp the role of PVD, it's helpful to compare it to another common technique: Chemical Vapor Deposition (CVD). While both create thin films, their underlying mechanisms are fundamentally different.

The Defining Difference: Physical vs. Chemical

The core distinction is simple: PVD is a physical process, moving material from A to B without changing its chemical nature. CVD is a chemical process, where gases react on the surface of the substrate to form a new solid material as the coating.

Coverage of Complex Shapes

Because PVD is a "line-of-sight" technique, it can struggle to coat complex, intricate geometries evenly. CVD excels at this, as the precursor gases can flow around an object, providing a uniform "wrap-around" coating.

Operating Conditions and Materials

PVD is often favored for depositing pure metals, alloys, and certain compounds that can be evaporated or sputtered. CVD is frequently used to grow specific crystalline structures like carbon nanotubes or to create highly pure films on semiconductors where a precise chemical reaction is required.

Making the Right Choice for Your Goal

Selecting the correct deposition method depends entirely on the material, the shape of the substrate, and the desired properties of the final coating.

- If your primary focus is applying a hard, durable coating of a high-melting-point material onto a relatively simple surface: PVD is the ideal choice for its strong adhesion and performance.

- If your primary focus is uniformly coating a complex, three-dimensional object with non-line-of-sight surfaces: CVD is the more effective method due to its gas-based, non-directional nature.

- If your primary focus is creating a film through a specific chemical reaction to achieve high purity or a unique crystalline structure: CVD provides the control needed for these specialized applications.

Ultimately, understanding the fundamental physical mechanism of PVD is the key to leveraging its unique ability to create powerful, high-performance surfaces.

Summary Table:

| Aspect | PVD (Physical Vapor Deposition) | CVD (Chemical Vapor Deposition) |

|---|---|---|

| Process Type | Physical (evaporation, sputtering) | Chemical (gas reaction) |

| Coating Uniformity | Line-of-sight; less uniform on complex shapes | Conformal; excellent for complex 3D objects |

| Typical Applications | Hard, wear-resistant coatings; high-melting-point materials | High-purity films; specific crystalline structures |

| Key Advantage | Excellent adhesion, dense coatings | Uniform "wrap-around" coating capability |

Need a high-performance coating solution for your laboratory equipment?

At KINTEK, we specialize in providing advanced lab equipment and consumables, including PVD systems, to help you achieve superior surface properties for your research or manufacturing needs. Our expertise ensures you get the right coating technology for enhanced durability, corrosion resistance, and performance.

Contact our experts today to discuss how PVD can benefit your specific application!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What are the forensic applications of XRF? Uncover the Elemental Fingerprint of Evidence

- What are the disadvantages of the Austempering process? Key Limitations and Trade-offs

- What is the temperature range of quartz glass? Master Its Thermal Limits for Demanding Applications

- How is cannabis distillate extracted? A Step-by-Step Guide to Ultra-Pure THC & CBD

- What is the sputtering process in SEM? A Guide to Preventing Charging for Clear Imaging

- What increases tensile strength? Key Methods to Enhance Material Strength and Performance

- What temperature does THC distillate evaporate? Master Your Vaping Experience with the Perfect Heat

- What is the meaning of sintering? A Guide to High-Strength, Complex Part Manufacturing