While there is no single standard pressure, a specific hydraulic press may have a recommended operating pressure around 250 kg/cm² and a maximum allowable pressure of 400 kg/cm². This internal system pressure is the key to the machine's operation, but it is not the same as the final force it delivers. The actual force, or "tonnage," is a product of this pressure and the size of the press's main cylinder.

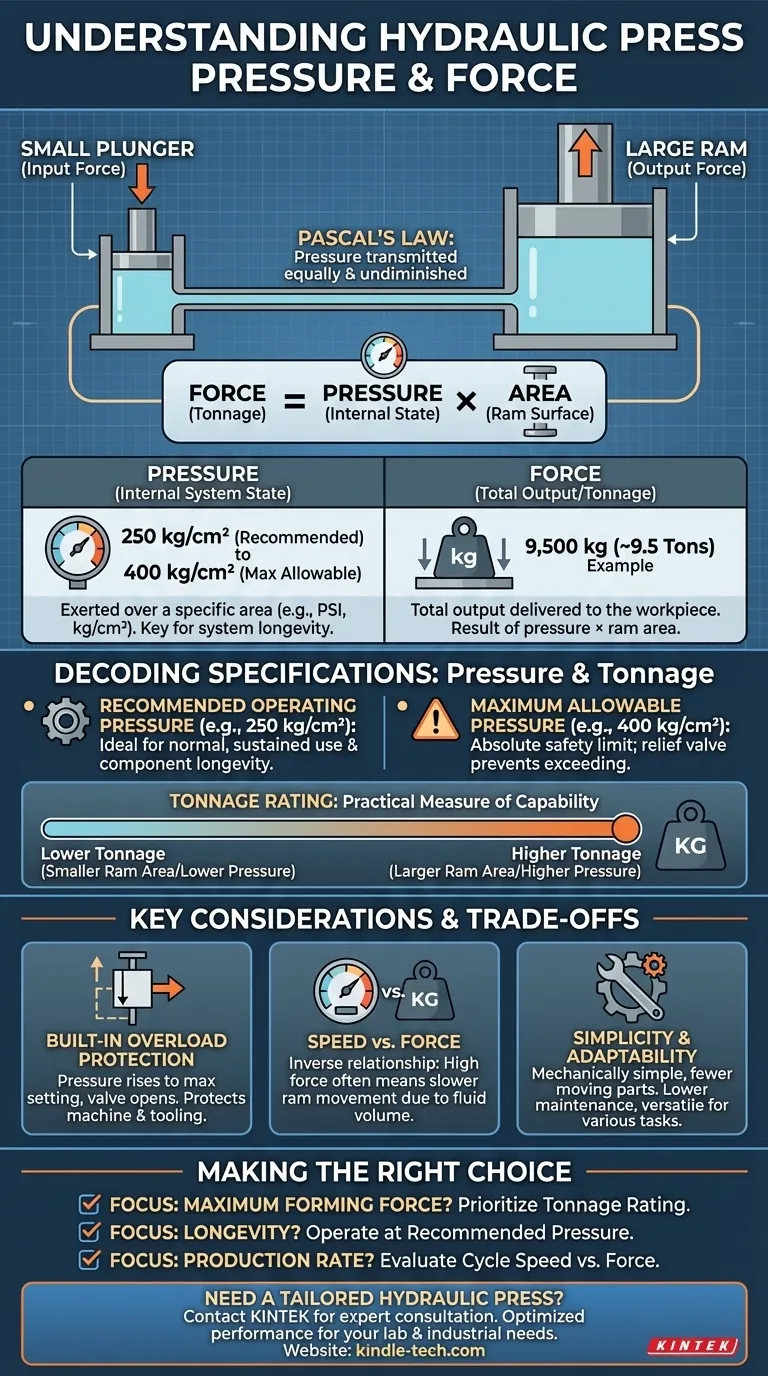

The critical insight is that a hydraulic press uses a constant, contained fluid pressure to multiply force. The machine's power comes not from the pressure value alone, but from applying that pressure over a large surface area, as defined by Pascal's Law.

The Principle Behind the Power: Pascal's Law

At its core, a hydraulic press is a straightforward force multiplier. Its operation is governed by a fundamental principle of fluid mechanics discovered centuries ago.

What is Pascal's Law?

Pascal's Law states that pressure applied to an enclosed, incompressible fluid is transmitted equally and undiminished to every portion of the fluid and the walls of the containing vessel.

In simple terms, if you generate 250 kg/cm² of pressure in one part of a sealed hydraulic system, that exact same pressure exists everywhere else within that system.

The Force Multiplier Effect

A press uses this principle with two interconnected cylinders of different sizes: a small one (the plunger) and a large one (the ram).

A small force is applied to the small plunger, creating pressure in the hydraulic fluid. This pressure is then transmitted to the much larger ram. Because the ram has a significantly larger surface area, the same pressure results in a much greater output force.

The formula is simple: Force = Pressure × Area.

Pressure vs. Force: A Critical Distinction

It is common for specifications to use terms like "power" and "kg" imprecisely. It is vital to distinguish between pressure and force.

- Pressure is the force exerted over a specific area (e.g., kg/cm² or PSI). This is the internal state of the hydraulic system.

- Force (or tonnage) is the total output the press can deliver (e.g., 9,500 kg or 15.2 tons). This is the result of the system pressure acting on the ram's area.

Decoding Hydraulic Press Specifications

When you review the specifications for a hydraulic press, the pressure and force ratings tell you about its performance and safety limits.

Maximum vs. Recommended Pressure

You will often see two pressure-related values:

- Recommended Pressure (e.g., 250 kg/cm²): This is the pressure for normal, sustained operation. Running at or below this level ensures the longevity of the seals, hoses, and mechanical components.

- Maximum Pressure (e.g., 400 kg/cm²): This is the absolute safety limit. The system is designed with a pressure relief valve to prevent exceeding this value, which would risk damage or catastrophic failure.

The Role of Tonnage

The "tonnage" rating (like the 9,500 kg or ~9.5 metric tons in the example) is the most practical measure of a press's capability. It tells you the maximum force the ram can exert on a workpiece.

This tonnage is the direct result of multiplying the system pressure by the surface area of the ram cylinder. For the same internal pressure, a press with a larger diameter ram will have a higher tonnage rating.

Understanding the Trade-offs

While hydraulic presses offer immense power, their operation involves inherent trade-offs that are important to understand for any application.

Built-in Overload Protection

A major advantage of hydraulic systems is their inherent safety. If the force required to perform an operation exceeds the press's capacity, the fluid pressure will rise until it hits the maximum setting of the relief valve.

The valve then opens, preventing any further increase in pressure. This protects both the machine and the expensive tooling or molds from damage due to overload.

Speed vs. Force

There is often an inverse relationship between the speed of the ram and the force it is exerting. Generating very high force requires the hydraulic pump to move a large volume of fluid, which can result in slower ram movement. Many industrial presses use complex circuits to allow for rapid approach and retraction, with slower speeds during the high-force pressing phase.

Simplicity and Adaptability

The design of a hydraulic press is mechanically simple, with fewer moving parts than a mechanical press. This leads to lower maintenance costs and greater reliability over time.

This simple design also makes them highly adaptable for a wide variety of production, assembly, and repair tasks, from forming sheet metal to pressing bearings.

Making the Right Choice for Your Application

Understanding these specifications allows you to choose and operate a press effectively. Your primary goal will determine which specification is most important.

- If your primary focus is maximum forming force: Concentrate on the tonnage rating (e.g., 15 tons), which is the most direct indicator of the machine's power.

- If your primary focus is tool and machine longevity: Operate consistently at or below the recommended pressure rating, not the absolute maximum.

- If your primary focus is production rate: Evaluate the ram's stroke speed (approach, pressing, and return) in relation to its force capacity to ensure it meets your cycle time needs.

By understanding the relationship between pressure, area, and force, you can select and operate any hydraulic press with precision and safety.

Summary Table:

| Specification | Typical Value | Description |

|---|---|---|

| Recommended Operating Pressure | 250 kg/cm² | Ideal pressure for normal, sustained use to ensure component longevity. |

| Maximum Allowable Pressure | 400 kg/cm² | Absolute safety limit; system includes a relief valve to prevent exceeding this. |

| Resulting Tonnage (Example) | 9,500 kg (~9.5 tons) | Total output force calculated from pressure and ram cylinder area (Force = Pressure × Area). |

Need a Hydraulic Press Tailored to Your Specific Force and Speed Requirements?

Understanding the precise relationship between pressure, area, and force is critical for selecting the right equipment. At KINTEK, we specialize in providing robust and reliable lab equipment, including hydraulic presses designed for a wide range of applications—from material testing and production to assembly and repair.

Our experts can help you choose a press with the perfect tonnage, speed, and safety features for your unique laboratory or industrial needs, ensuring optimal performance and longevity.

Contact KINTEL today for a personalized consultation and discover how our hydraulic presses can enhance your efficiency and precision!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Heat Press Machine

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis