At its core, the principle of an RF plasma source is to use energy from radio frequency (RF) electromagnetic waves to transform a neutral gas into an energized state of matter known as plasma. This is achieved by applying a high-frequency electric field to a low-pressure gas, which accelerates free electrons that then collide with and ionize gas atoms, creating a cascade that sustains the plasma.

The fundamental concept is not merely creating plasma, but using an oscillating RF field to efficiently pump energy into a gas. This creates a controlled, sustainable source of ions and reactive chemical species essential for high-tech industrial processes like semiconductor manufacturing and materials science.

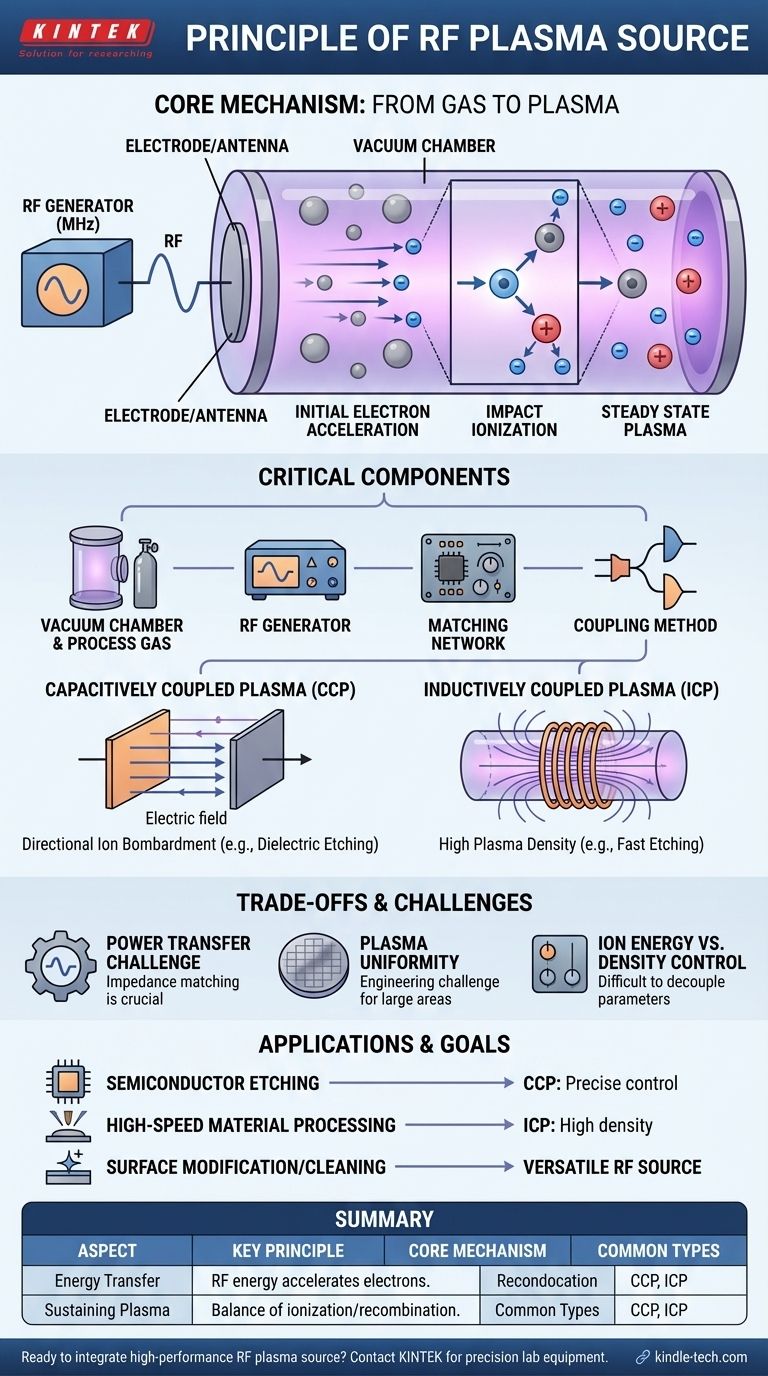

The Core Mechanism: From Gas to Plasma

To truly understand the principle, we must break down the process of energy transfer from the RF field to the gas. It is a precise, multi-stage event that occurs within fractions of a second.

The Role of the RF Field

An RF generator produces a high-frequency alternating current, typically in the megahertz (MHz) range. This current is delivered to an electrode or antenna, which radiates the energy as an oscillating electromagnetic field inside a vacuum chamber.

Initial Electron Acceleration

Any low-pressure gas contains a few stray free electrons. The oscillating electric field grabs these electrons and accelerates them, first in one direction, then the opposite, thousands or millions of times per second. Because electrons are incredibly light, they can absorb energy from the field very efficiently.

The Ionization Cascade

As these energized electrons race through the gas, they collide with neutral gas atoms. If an electron has gained enough kinetic energy, its impact will be strong enough to knock another electron off a neutral atom.

This process, called impact ionization, creates two things: a new free electron and a positively charged ion. These two new electrons are then accelerated by the RF field, leading to more collisions and creating even more electrons and ions in a self-sustaining chain reaction.

Reaching a Steady State

This avalanche does not continue indefinitely. A balance is eventually reached where the rate of new ion-electron pairs being created is equal to the rate at which they are lost, either by recombining into neutral atoms or by colliding with the chamber walls. The amount of RF power supplied directly controls the density and energy of this steady-state plasma.

How an RF Plasma System is Built

The principle is put into practice using a set of critical components, each serving a specific function to control the plasma environment.

The Vacuum Chamber and Gas

The entire process occurs in a sealed chamber pumped down to a low pressure. This is crucial because it reduces the density of gas atoms, allowing electrons to travel far enough to gain sufficient energy between collisions for ionization to occur. A specific process gas (like Argon, Oxygen, or a complex mixture) is then introduced at a controlled flow rate.

The RF Generator and Matching Network

The RF generator is the power supply. However, simply connecting it to the chamber is inefficient. A matching network is an essential circuit placed between the generator and the plasma chamber. Its job is to fine-tune the electrical impedance to ensure maximum power is transferred to the plasma and not reflected back to the generator, which could cause damage and inconsistent results.

The Coupling Method: CCP vs. ICP

There are two primary methods for coupling the RF energy into the gas.

- Capacitively Coupled Plasma (CCP): This method uses two parallel plate electrodes inside the chamber, creating an electric field between them, much like a capacitor. It is widely used for processes requiring directional ion bombardment, like dielectric etching.

- Inductively Coupled Plasma (ICP): This method uses a coil, often wrapped around a ceramic part of the chamber. The RF current in the coil creates a time-varying magnetic field, which in turn induces an electric field inside the chamber. ICP sources can achieve much higher plasma densities and are favored for fast, high-volume etching.

Understanding the Trade-offs

While powerful, RF plasma technology is not without its complexities and limitations. Understanding these is key to its successful application.

The Power Transfer Challenge

The plasma's impedance changes based on gas type, pressure, and power. This means the matching network must constantly adjust, either manually or automatically, to maintain efficient power transfer. A poor match leads to wasted energy and unstable process conditions.

Plasma Uniformity and Scalability

Creating a perfectly uniform plasma—where the density and energy are the same everywhere—is a significant engineering challenge, especially over large areas like a 300mm silicon wafer. Non-uniformity can lead to inconsistent etching or deposition across the substrate. This is a primary constraint on scalability.

Control of Ion Energy vs. Ion Density

In many RF systems, especially CCP, the RF power influences both the plasma density (the number of ions) and the ion energy (how hard they hit the surface). Decoupling these two parameters to control them independently is difficult and often requires more complex, multi-frequency source designs.

Applying This to Your Goal

The choice and configuration of an RF plasma source are dictated entirely by the desired outcome of the process.

- If your primary focus is precise semiconductor etching: You need excellent control over ion energy and directionality, making a CCP source a common and reliable choice.

- If your primary focus is high-speed material removal or deposition: You need a high-density plasma, pointing toward an ICP source for its superior ionization efficiency.

- If your primary focus is surface modification or cleaning: Versatility is key. A simpler, lower-power RF source may be sufficient to generate the reactive chemical species needed without causing damage from ion bombardment.

Ultimately, the principle of RF plasma is a cornerstone of modern technology, enabling the fabrication of the microchips and advanced materials that define our world.

Summary Table:

| Aspect | Key Principle |

|---|---|

| Core Mechanism | RF energy accelerates electrons to ionize gas atoms, creating a self-sustaining plasma. |

| Energy Transfer | An oscillating RF field efficiently transfers energy to free electrons via an antenna or electrodes. |

| Sustaining Plasma | A balance is reached between ionization and recombination, controlled by RF power. |

| Common Types | Capacitively Coupled Plasma (CCP) and Inductively Coupled Plasma (ICP). |

Ready to integrate a high-performance RF plasma source into your lab? KINTEK specializes in precision lab equipment, including plasma systems for semiconductor manufacturing and materials science. Our experts can help you select the right configuration—whether it's a CCP source for precise etching or an ICP source for high-density plasma—ensuring optimal process control and results. Contact our team today to discuss your specific application and how our solutions can accelerate your research and development.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Rotating Platinum Disk Electrode for Electrochemical Applications

- RRDE rotating disk (ring disk) electrode / compatible with PINE, Japanese ALS, Swiss Metrohm glassy carbon platinum

People Also Ask

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating