At its core, the principle of a sintering furnace is to use controlled heat, and sometimes pressure, to transform a powdered or granular material into a solid, dense object. This process, known as sintering, works by encouraging atoms on the surface of individual particles to diffuse and bond with neighboring particles, fusing them together without fully melting the entire material.

The fundamental purpose of any sintering furnace is not to melt the material, but to create a precise thermal and atmospheric environment where solid-state atomic diffusion can occur, eliminating the voids between particles to form a coherent, strengthened mass.

The Core Principle: Atomic Diffusion, Not Melting

The concept of sintering can feel counter-intuitive. You are making a solid from a powder by heating it, but critically, you are keeping the temperature below the material's melting point. The furnace is the tool that makes this transformation possible.

What is Sintering?

Sintering is a thermal treatment that causes particles to bond, increasing the material's strength and density. It's a process driven by the reduction of surface energy.

Imagine a bucket of soap bubbles; over time, smaller bubbles merge to form larger ones because it's a more stable, lower-energy state. Sintering works on a similar principle at an atomic level.

The Role of Heat and Contact Points

Heat provides the energy. It excites the atoms within the material, giving them the mobility to move or "diffuse" from one particle to another across the points where they touch.

As this diffusion happens, the boundaries between the original particles slowly disappear, and the small voids or pores between them shrink and are eliminated.

The Goal: Reducing Voids and Increasing Density

The ultimate objective is to create a dense, solid object from a loose powder. The furnace's job is to manage the environment—temperature, atmosphere, and sometimes pressure—to maximize this diffusion process efficiently and effectively.

Key Furnace Functions That Enable Sintering

Different furnace designs exist, but they all manipulate the same fundamental environmental factors to achieve successful sintering.

Controlling Temperature

This is the primary driver of sintering. Heating elements, often electrical resistance or induction coils, raise the material's temperature to a precise point where atomic diffusion is active but bulk melting has not begun.

Induction furnaces, for example, use an alternating current in a coil to induce eddy currents directly within the material, generating heat internally for extremely rapid and efficient heating.

Controlling the Atmosphere

The environment inside the furnace is critical. Many materials, especially metals, will rapidly oxidize at high temperatures if exposed to air, which prevents proper bonding.

A vacuum sintering furnace addresses this by pumping out the air, creating a clean environment that prevents oxidation and contamination. This results in higher purity and better performance in the final product.

Applying Mechanical Pressure

For some advanced materials like high-performance ceramics, heat alone isn't enough to achieve the desired density.

A hot press sintering furnace combines high temperature with high mechanical pressure. The pressure physically forces the particles closer together, increasing the number of contact points and accelerating the diffusion and densification process.

Common Sintering Furnace Architectures

While the principles of heat and atmosphere are universal, the mechanical design of a furnace is often tailored to a specific process or production volume.

Batch vs. Continuous Processing

A bottom-loading furnace is a type of batch furnace where the load is lifted from below into a uniformly heated chamber. This design provides excellent temperature uniformity for high-quality, single-batch processing.

In contrast, a walking-beam furnace is designed for continuous, high-volume production. It uses a mechanical system to "walk" carriers of material through different temperature zones, moving from heating to cooling in a steady flow.

The Importance of Structural Design

Furnaces that operate under extreme conditions, like a hot press, require very high structural and manufacturing accuracy. Except for the heating elements, the furnace body must be aggressively cooled to withstand the immense heat and pressure.

Understanding the Trade-offs

Choosing a sintering method involves balancing performance requirements with operational complexity and cost. No single furnace design is best for every application.

Density vs. Purity

A hot press furnace delivers superior density but introduces complexity with its pressure system. A vacuum furnace prioritizes purity and is essential for reactive materials, but may not achieve the same density as a hot press.

Throughput vs. Precision

Continuous systems like walking-beam furnaces are built for industrial scale and efficiency. Batch furnaces, like bottom-loaders, offer superior control over the heating and cooling cycles for a specific part, which is often critical for research or producing complex components.

Cost and Complexity

Adding systems for vacuum or high pressure significantly increases a furnace's initial cost, operational complexity, and maintenance requirements. The simplest furnaces control only temperature and are used for materials that are not sensitive to atmosphere.

Making the Right Choice for Your Goal

Selecting the correct furnace technology depends entirely on the material you are working with and the desired properties of the final product.

- If your primary focus is maximum density and mechanical strength: A hot press sintering furnace is the ideal choice, as the combination of heat and pressure accelerates densification.

- If your primary focus is material purity and preventing oxidation: A vacuum sintering furnace is non-negotiable for processing reactive metals or achieving pristine material properties.

- If your primary focus is high-volume, continuous industrial production: A furnace with a transport mechanism like a walking beam is designed for efficiency and throughput.

Ultimately, understanding these core principles empowers you to select not just a piece of equipment, but the precise environment required to transform powdered materials into high-performance solids.

Summary Table:

| Furnace Type | Primary Function | Key Advantage | Ideal For |

|---|---|---|---|

| Vacuum Furnace | Sinters in a clean, oxygen-free environment | Prevents oxidation, ensures high purity | Reactive metals, high-purity materials |

| Hot Press Furnace | Combines heat with high mechanical pressure | Maximizes density and mechanical strength | High-performance ceramics, advanced composites |

| Walking-Beam Furnace | Continuous processing through temperature zones | High-volume, industrial-scale production | Mass manufacturing, consistent throughput |

| Batch Furnace (e.g., Bottom-Loading) | Processes single loads with precise control | Superior temperature uniformity, ideal for R&D | Complex components, research applications |

Ready to Transform Your Materials with Precision Sintering?

Understanding the principle is the first step; applying it is where KINTEK excels. Whether you need the ultimate purity of a vacuum furnace, the extreme density of a hot press, or the high throughput of a continuous system, the right sintering environment is critical to your success.

KINTEK specializes in advanced lab equipment, including sintering furnaces tailored to your specific material and production goals. Our experts will help you select the perfect furnace to achieve the strength, density, and purity your application demands.

Contact us today to discuss your project and discover how KINTEK's solutions can enhance your laboratory's capabilities.

Get in touch with our experts now →

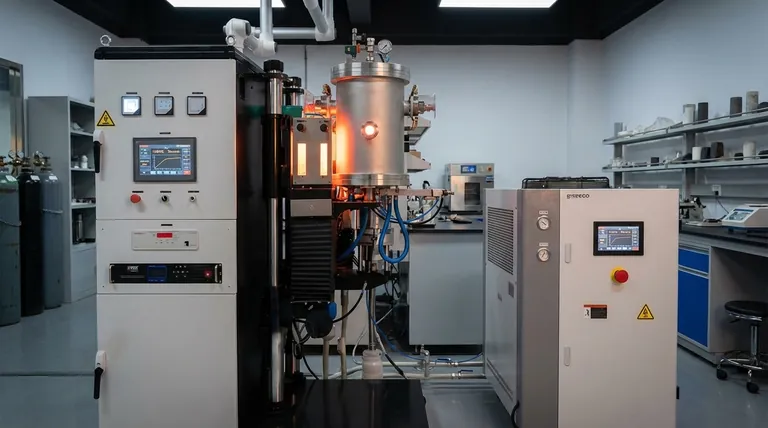

Visual Guide

Related Products

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

People Also Ask

- Why is sintering easier in the presence of a liquid phase? Unlock Faster, Lower-Temperature Densification

- What are the factors influencing shrinkage during sintering? Control Dimensional Changes for Precision Parts

- Why is a high vacuum environment necessary in sintering equipment for TiAl alloys? Ensure High-Purity Metal Bonding

- How does a high-temperature vacuum sintering furnace facilitate the post-treatment of Zirconia coatings?

- Why must green bodies produced via binder jetting undergo treatment in a vacuum sintering furnace?