At its core, arc melting is a process that uses the intense heat of an electric arc to melt metals and other materials. This method generates a high-temperature plasma arc between graphite electrodes and the metallic charge, functioning like a controlled bolt of lightning to rapidly liquefy materials with high melting points, most notably steel scrap.

The fundamental difference between melting technologies lies in how they generate heat. Arc melting uses a direct, high-energy plasma arc for massive-scale operations, while processes like induction melting use an indirect magnetic field for more controlled, smaller-batch applications.

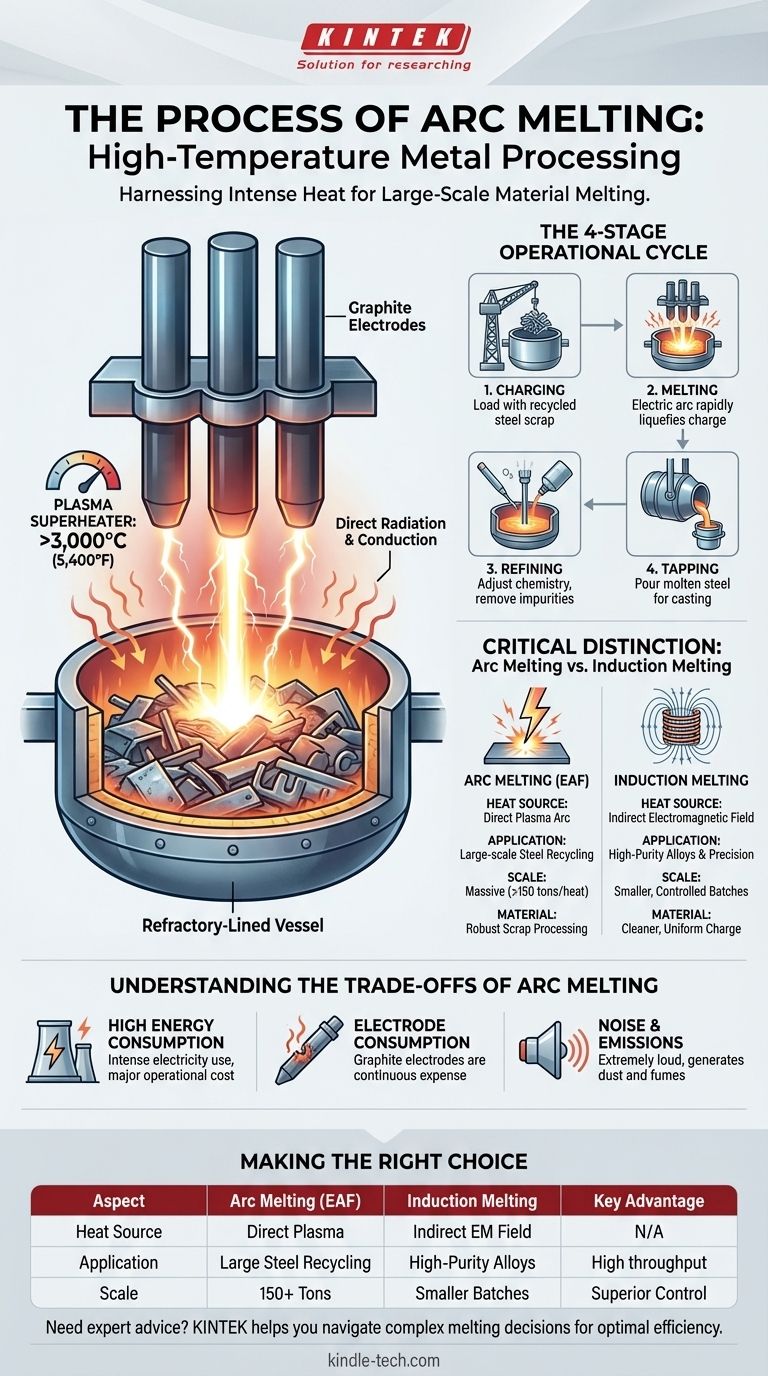

How Arc Melting Works: The Core Mechanism

Electric Arc Furnaces (EAFs) are the workhorses of modern steel recycling. Understanding their operation is key to understanding their role in heavy industry.

The Electric Arc: A Plasma Superheater

The heat source is an electric arc. This is not a simple flame; it is a sustained electrical discharge through a gas, creating a plasma that can reach temperatures exceeding 3,000°C (5,400°F).

This extreme heat is transferred directly to the metal charge through radiation and conduction, allowing for extremely rapid melting.

The Key Components: Electrodes and Furnace

The process relies on a few critical components. Graphite electrodes, massive consumable columns, are used to conduct the high-power electricity needed to create and sustain the arc.

These electrodes are positioned above the metal charge inside a refractory-lined, bowl-shaped steel vessel. The entire furnace can tilt to pour off, or "tap," the molten metal once the process is complete.

The Step-by-Step Process

The operational cycle of an arc furnace follows four main stages:

- Charging: The furnace is loaded (charged) with material, which is most often recycled steel scrap.

- Melting: The roof is closed, and the electrodes are lowered. A powerful electric current is applied, striking an arc to the scrap metal. The intense heat rapidly melts the charge into a liquid bath.

- Refining: Once melted, the chemistry of the liquid steel is tested and adjusted. Oxygen may be injected to remove impurities like carbon, and alloys are added to meet the specific grade requirements.

- Tapping: The furnace is tilted, and the molten steel is poured into a ladle for transfer to the next stage of production, typically casting.

Arc Melting vs. Induction Melting: A Critical Distinction

Your question referenced induction melting, and it's crucial to distinguish between these two dominant technologies as they serve different purposes. They are not interchangeable.

The Heat Source: Direct vs. Indirect

The primary difference is the heating method. Arc melting is a direct heating process where the plasma arc makes direct contact with the charge material.

Induction melting, in contrast, is an indirect process. It uses an electromagnetic field to induce an electric current within the metal itself, causing it to heat up and melt from the inside out without any external arc or flame.

Scale and Application

Arc furnaces are built for massive scale. They are the standard for steel "mini-mills," capable of melting over 150 tons of scrap in a single heat (a single production cycle).

Induction furnaces are generally used for smaller, more precise applications. They excel in foundries producing high-quality castings or creating specialty alloys where tight control over temperature and chemistry is paramount.

Material Handling and Purity

Arc furnaces are exceptionally robust and can efficiently melt large, non-uniform pieces of scrap metal, including entire automobiles. The refining stage is designed to handle the impurities common in scrap.

Induction furnaces require a cleaner and more uniform charge material. Their primary strength is maintaining purity, not removing large amounts of impurities.

Understanding the Trade-offs of Arc Melting

While powerful, the EAF process has inherent trade-offs that are critical to understand from an operational standpoint.

High Energy Consumption

Creating and sustaining a high-power plasma arc requires an immense amount of electricity, making energy a major operational cost. EAF operations can cause significant fluctuations on a local power grid.

Electrode Consumption

The graphite electrodes are not permanent; they are consumed during the melting process through oxidation and sublimation. This represents another significant and continuous operational expense.

Noise and Emissions

The arc melting process is extremely loud and generates significant dust and fumes. This necessitates robust environmental controls and safety measures for noise and air quality management.

Making the Right Choice for Your Goal

Selecting a melting technology depends entirely on your specific industrial objective.

- If your primary focus is large-scale steel recycling: The Electric Arc Furnace is the undisputed industry standard due to its high throughput, speed, and unmatched ability to process scrap metal.

- If your primary focus is producing high-purity specialty alloys: Induction melting provides superior control over metal chemistry and temperature, making it the ideal choice for applications demanding precision.

- If your primary focus is casting non-ferrous metals like aluminum or copper alloys: Induction melting is often preferred for its cleaner operation and the metallurgical benefits of its electromagnetic stirring action.

Ultimately, choosing the right tool requires a clear understanding of the material you are melting and the scale at which you need to operate.

Summary Table:

| Aspect | Arc Melting (EAF) | Induction Melting |

|---|---|---|

| Heat Source | Direct plasma arc | Indirect electromagnetic field |

| Primary Application | Large-scale steel recycling | High-purity alloys, precision casting |

| Typical Scale | 150+ tons per heat | Smaller, controlled batches |

| Charge Material | Robust, handles varied scrap | Cleaner, more uniform material |

| Key Advantage | High throughput, scrap processing | Superior temperature/chemistry control |

Need expert advice on selecting the right melting technology for your lab or production facility?

The choice between arc melting and induction melting is critical for achieving your specific material and production goals. KINTEK specializes in lab equipment and consumables, serving laboratory needs with precision and expertise. Our team can help you navigate these complex decisions to ensure optimal efficiency, purity, and cost-effectiveness for your operations.

Contact KINTEK today to discuss your project requirements and discover the ideal solution for your metal melting challenges.

Visual Guide

Related Products

- Vacuum Arc Induction Melting Furnace

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

People Also Ask

- Can you braze copper to brass without flux? Yes, but only under these specific conditions.

- What is the range of pyrolysis? Master Temperature Control for Optimal Bio-Product Yields

- What are the advantages of brazing over soldering? Achieve Superior Strength and High-Temperature Performance

- What are the advantages of brazing over braze welding? Achieve Stronger, Cleaner, and Repeatable Joints

- What is 1800 degrees Celsius furnace? A Guide to High-Temperature Materials Processing

- Why is an ultra-high temperature furnace (1800°C) required for Si-O-C ceramics carbothermal reduction?

- What is the primary purpose of using a vacuum drying oven for high entropy alloy powders? Achieve Maximum Material Purity

- What is the range for heat treating? The Goal-Defined Temperature Guide