In essence, lignocellulosic biomass pretreatment is a crucial processing step designed to break down the rigid and complex structure of plant matter. This process makes the internal components, primarily cellulose and hemicellulose, accessible for conversion into biofuels, bioplastics, and other high-value chemicals. It achieves this by employing a range of methods—including physical, chemical, and biological treatments—to disrupt the protective lignin sheath and increase the material's surface area.

The core challenge of using biomass is its natural resistance to decomposition. Pretreatment is not just one process, but a strategic decision to overcome this resistance, unlocking the valuable sugars and polymers locked within the plant's cellular walls. The right method is a trade-off between effectiveness, cost, and the desired end product.

Why Pretreatment is the Critical First Step

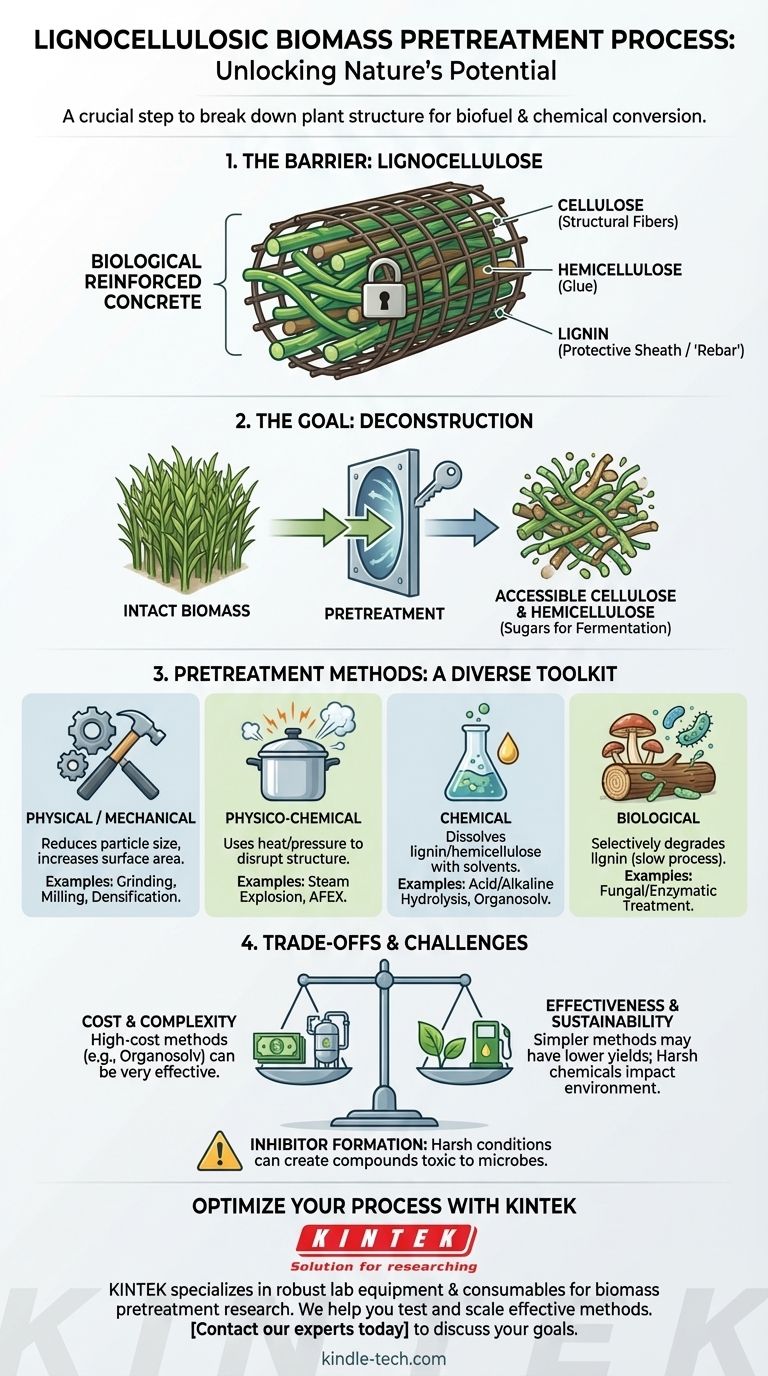

To grasp the need for pretreatment, you must first understand the structure of lignocellulosic biomass. Think of it as a biological reinforced concrete.

The Lignocellulose Barrier

Lignocellulose is composed of three main biopolymers: cellulose, hemicellulose, and lignin.

Cellulose fibers provide structural strength, like the aggregate in concrete. Hemicellulose acts as a glue, binding the cellulose fibers together.

Lignin is the most critical barrier. It's a complex, rigid polymer that encases the cellulose and hemicellulose, acting like steel rebar, providing immense structural integrity and preventing enzymes or chemicals from accessing the valuable sugars within.

The Goal: Deconstruction

The primary goal of pretreatment is to deconstruct this "reinforced concrete." An effective process will increase the accessible surface area and remove or alter the lignin sheath.

This deconstruction makes the cellulose and hemicellulose vulnerable to the next stage of conversion, whether that is enzymatic hydrolysis to produce sugars for fermentation or another chemical conversion pathway.

A Breakdown of Pretreatment Methods

Pretreatment methods are diverse and are often combined to achieve the desired outcome. They can be broadly grouped into four categories.

Physical and Mechanical Methods

These methods use physical force to reduce the size and increase the surface area of the biomass.

Examples include grinding, milling, and densification (creating pellets or briquettes). While essential for improving handling and transport, these methods alone are often insufficient for significant structural disruption.

Physico-Chemical Methods

This category uses a combination of heat, pressure, and sometimes chemicals to explosively decompress the biomass, tearing its structure apart.

Steam explosion is a common example where biomass is subjected to high-pressure steam before the pressure is suddenly released. A similar process, Ammonia Fiber Explosion (AFEX), uses hot, liquid ammonia to achieve a similar disruptive effect.

Chemical Methods

Chemical methods use solvents or catalysts to dissolve parts of the lignocellulosic structure, primarily lignin and hemicellulose.

Acid hydrolysis uses dilute or concentrated acids to break down hemicellulose and make cellulose more accessible. Alkaline hydrolysis uses bases like sodium hydroxide to remove lignin.

Organosolv processes use organic solvents to separate high-quality lignin, which itself can be a valuable co-product. Other methods like ozonolysis and wet oxidation use oxidizing agents to break down lignin.

Biological Methods

These methods use microorganisms, typically fungi, or their enzymes to selectively degrade lignin and hemicellulose.

While highly specific and environmentally friendly, biological pretreatment is often very slow compared to chemical or physical methods, making it a challenge for industrial-scale operations.

Understanding the Trade-offs and Challenges

There is no single "best" pretreatment method. The choice involves navigating a complex set of technical and economic trade-offs.

Cost vs. Effectiveness

Highly effective methods, such as those using concentrated acids or specialized solvents (organosolv), often come with high capital and operational costs. They may require corrosion-resistant reactors and extensive solvent recovery systems.

Simpler methods like grinding or steam explosion may be cheaper but less effective, resulting in lower yields in the subsequent conversion steps.

Formation of Inhibitors

A major challenge with many chemical and physico-chemical methods is the formation of inhibitory compounds. Harsh conditions can degrade the sugars and lignin into products like furfural and phenols.

These inhibitors can be toxic to the microbes used in downstream fermentation, significantly reducing the efficiency of biofuel production. This requires additional detoxification steps, adding cost and complexity.

Sustainability and Environmental Impact

The "green" promise of biomass can be undermined by the pretreatment process itself. Using harsh acids, bases, or organic solvents creates waste streams that must be managed.

The energy consumption of high-temperature, high-pressure processes is also a significant consideration that impacts the overall sustainability and carbon footprint of the entire biorefinery concept.

Making the Right Choice for Your Goal

The optimal pretreatment strategy is defined entirely by your final objective. Before selecting a method, you must clearly define what product you intend to create.

- If your primary focus is biofuel production via fermentation: You need a method like dilute acid hydrolysis or steam explosion that maximizes sugar release while minimizing the formation of fermentation inhibitors.

- If your primary focus is creating high-value bioplastics or polymers: A method like the organosolv process is ideal because it cleanly separates high-purity lignin and cellulose, providing two valuable feedstock streams.

- If your primary focus is direct energy generation via pyrolysis: Your pretreatment is much simpler, focusing on mechanical densification into pellets or briquettes to ensure uniform handling and efficient thermochemical conversion.

Ultimately, mastering biomass conversion hinges on understanding that pretreatment is the strategic key that unlocks the material's hidden value.

Summary Table:

| Pretreatment Method Category | Key Examples | Primary Action |

|---|---|---|

| Physical/Mechanical | Grinding, Milling | Reduces particle size, increases surface area |

| Physico-Chemical | Steam Explosion, AFEX | Uses heat/pressure to disrupt structure |

| Chemical | Acid/Alkaline Hydrolysis, Organosolv | Dissolves lignin/hemicellulose with solvents |

| Biological | Fungal/Enzymatic Treatment | Selectively degrades lignin (slow process) |

Ready to optimize your biomass conversion process? The right pretreatment method is critical to your success, whether you're producing biofuels, bioplastics, or high-value chemicals. KINTEK specializes in providing robust lab equipment and consumables tailored for biomass pretreatment research and development. Our solutions help you test and scale the most effective methods while managing cost and sustainability. Let's discuss your specific biomass goals – contact our experts today to find the ideal equipment for your lab's needs.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

People Also Ask

- How are rotary kilns heated? Direct vs. Indirect Heating Methods Explained

- What are the problems of rotary kiln of cement and their remedies? Achieve Long-Term Reliability and Efficiency

- What are the advantages of pyrolysis in waste management? Turn Waste into Fuel and Valuable Resources

- What is the temperature range of a rotary kiln? A Guide to Custom Thermal Profiles

- How much energy is needed for pyrolysis? Achieve a Self-Sustaining Operation

- What is the application of catalytic pyrolysis? Upgrade Waste into High-Value Biofuel & Chemicals

- What are the methods for pyrolysis for charcoal production biochar production? Slow vs. Fast Pyrolysis Explained

- Where are fluidized bed reactors used? Powering Chemical, Petroleum, and Energy Processes