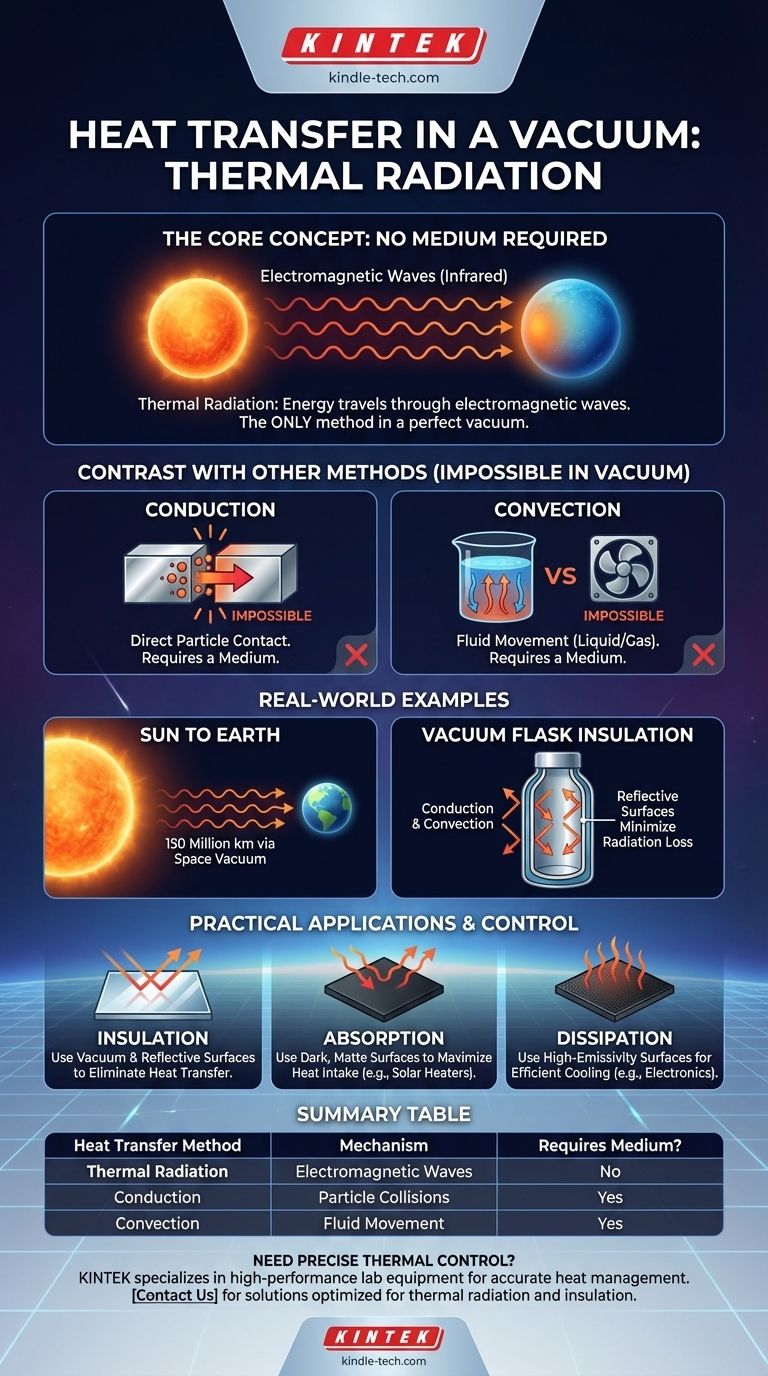

In a vacuum, the process of heat transfer is called thermal radiation. Unlike other forms of heat transfer, such as conduction or convection, radiation does not require any physical medium. Instead, energy travels through the void in the form of electromagnetic waves, similar to how light travels from the sun to the Earth.

The critical takeaway is that while conduction and convection rely on the movement and collision of particles, thermal radiation is a fundamental process where energy is transported by electromagnetic waves. This is the only way heat can travel through the perfect vacuum of space.

How Radiation Transfers Heat Without a Medium

The idea that heat can move through "nothing" can seem counter-intuitive. The mechanism is rooted in the physics of all matter.

The Role of Electromagnetic Waves

Every object with a temperature above absolute zero (0 Kelvin) emits thermal energy. This energy is released as electromagnetic waves, primarily in the infrared part of the spectrum, which are invisible to the human eye.

These waves carry energy away from the emitting object. They are a fundamental property of the thermal motion of charged particles within atoms.

The Process of Emission and Absorption

Imagine two objects in a vacuum. The hotter object emits more radiant energy than the cooler one.

When the electromagnetic waves from the hotter object strike the cooler object, they are absorbed. This absorption transfers energy, causing the particles in the cooler object to vibrate more intensely, which we measure as an increase in its temperature.

The Sun: Our Ultimate Example

The most familiar example is the sun heating the Earth. The sun is an incredibly hot body that radiates enormous amounts of energy into space.

This energy travels over 150 million kilometers through the vacuum of space. When it reaches Earth, it is absorbed by the atmosphere, land, and oceans, warming our planet and making life possible.

Radiation vs. Other Heat Transfer Methods

Understanding radiation becomes clearer when contrasted with the other two methods of heat transfer, which are impossible in a vacuum.

Conduction: Transfer Through Touch

Conduction is the transfer of heat through direct physical contact. Heat moves from a hotter part of an object to a colder part as vibrating atoms and molecules collide with their neighbors.

A classic example is a metal spoon heating up when placed in hot coffee. Without particles to collide, conduction cannot occur in a vacuum.

Convection: Transfer Through Flow

Convection is the transfer of heat through the movement of fluids (liquids or gases). Warmer, less dense fluid rises, and cooler, denser fluid sinks, creating a convection current that distributes heat.

This is how a furnace heats a room or water boils in a pot. Since there is no gas or liquid to move in a vacuum, convection is impossible.

Practical Implications and Nuances

The principles of thermal radiation have profound effects on engineering and everyday life, especially when it comes to insulation.

Vacuum as an Insulator

Because a vacuum prevents both conduction and convection, it is an exceptionally effective insulator. This is the principle behind a vacuum flask (like a Thermos).

The flask has an inner and outer wall separated by a vacuum. This gap stops heat from being conducted or convected out of the hot liquid inside.

The Importance of Surface Properties

However, heat can still be lost through radiation. This is why vacuum flasks have shiny, silvered surfaces on the inside of the vacuum gap.

Polished, reflective surfaces are poor emitters (and absorbers) of thermal radiation. Conversely, dark, matte surfaces are excellent emitters and absorbers. This is why solar water heaters are often painted matte black to absorb as much solar energy as possible.

Applying This to Your Goal

Understanding the unique nature of thermal radiation allows you to control heat transfer in various applications.

- If your primary focus is insulation: Use a vacuum gap to eliminate conduction and convection, and use highly reflective surfaces to minimize heat loss or gain from radiation.

- If your primary focus is heat absorption: Use dark, matte surfaces that are designed to absorb the maximum amount of incoming radiation.

- If your primary focus is heat dissipation: Use surfaces with high emissivity (often dark and matte) to radiate unwanted heat away as efficiently as possible, a key principle in cooling electronics or spacecraft.

Mastering the control of thermal radiation is fundamental to engineering everything from a simple coffee thermos to a satellite orbiting the Earth.

Summary Table:

| Heat Transfer Method | Mechanism | Requires a Medium? |

|---|---|---|

| Thermal Radiation | Electromagnetic waves (e.g., infrared) | No |

| Conduction | Direct particle collisions | Yes |

| Convection | Fluid movement (liquids/gases) | Yes |

Need precise thermal control for your lab or industrial process? KINTEK specializes in high-performance lab equipment and consumables designed to manage heat transfer with accuracy and reliability. Whether you require advanced insulation solutions or systems optimized for thermal radiation, our expertise ensures your laboratory operates at peak efficiency. Contact us today to discuss how we can support your specific thermal management needs!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the purpose of using a vacuum oven for extended drying periods? Optimize Composite Polymer Electrolyte Prep

- What is classification of heating furnace? A Guide to Selecting the Right Industrial Furnace

- Can you get an electrical arc in vacuum? How High Voltage Creates Plasma in a Void

- Why is a high-vacuum pumping system necessary during the gas-phase hydrogenation of Zr1Nb alloys? Ensure Material Purity

- What is the tightness rate of a leak? Quantify Your Seal's Performance

- How does arc melting work? A Guide to High-Purity Metal and Alloy Production

- What is the use of vacuum hardening? Achieve Superior Hardness with a Clean, Bright Finish

- What role does a high-temperature sintering furnace play in NZSP fabrication? Key to Optimal Ionic Conductivity