At its core, vacuum coating is a high-tech process where a thin, solid film of material is deposited onto a surface, atom by atom, within a vacuum chamber. This process involves vaporizing a source material (like a metal), which then travels through the vacuum and condenses onto the target object—known as the substrate—to form a tightly bonded, high-performance coating.

The true value of vacuum coating isn't just applying a layer; it's about fundamentally engineering a surface. By manipulating materials at an atomic level, this process imparts properties like extreme hardness, corrosion resistance, or specific optical characteristics that are impossible to achieve with traditional paints or platings.

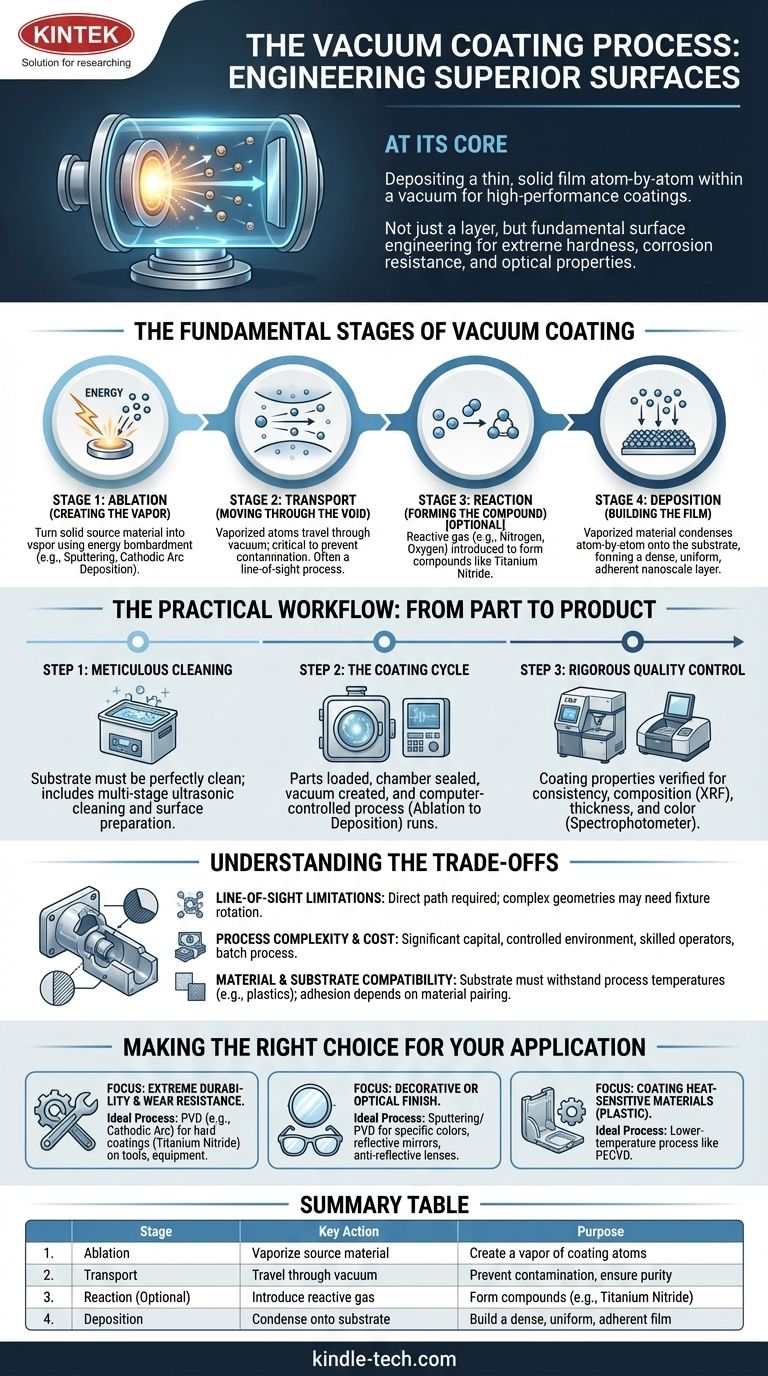

The Fundamental Stages of Vacuum Coating

To understand how vacuum coating works, it's best to break it down into four distinct physical stages. These stages happen in rapid succession inside the vacuum chamber.

Stage 1: Ablation - Creating the Vapor

The process begins by turning a solid source material into a vapor. This is not done by simple melting, but by bombarding the source "target" with energy.

Methods like sputtering use an ionized gas to physically knock atoms off the target. Another common method, cathodic arc deposition, uses a high-current electric arc to vaporize the material.

Stage 2: Transport - Moving Through the Void

Once vaporized, these atoms or molecules travel through the vacuum chamber. The vacuum is critical because it removes air and other particles that would otherwise interfere with or contaminate the coating.

This travel is typically in a straight line, which is why many vacuum coating methods are considered "line-of-sight" processes.

Stage 3: Reaction - Forming the Compound (Optional)

In many cases, a reactive gas (like nitrogen or oxygen) is introduced into the chamber. As the vaporized metal atoms travel, they react with this gas.

This is how compounds like Titanium Nitride (for hardness) or Zirconium Oxide are formed, allowing for a wide range of engineered coating properties.

Stage 4: Deposition - Building the Film

Finally, the vaporized material (or newly formed compound) reaches the substrate and condenses onto its surface. Because this happens atom by atom, the film grows into a highly dense, uniform, and strongly adhered layer with nanoscale thickness.

The Practical Workflow: From Part to Product

While the physics occurs in four stages, a commercial vacuum coating job follows a strict operational workflow to ensure quality and consistency.

Step 1: Meticulous Cleaning and Pretreatment

The substrate (the part being coated) must be perfectly clean. Any oils, dirt, or oxides will prevent the coating from adhering properly. This step often involves multi-stage ultrasonic cleaning and other surface preparation techniques.

In some cases, a pretreatment is applied to further enhance the adhesion of the coating to the substrate.

Step 2: The Coating Cycle

The clean parts are loaded into the vacuum chamber. The chamber is sealed, and powerful pumps create the vacuum. The coating process itself—ablation, transport, reaction, and deposition—is then run under precise computer control.

Step 3: Rigorous Quality Control

After the cycle, the coating's properties must be verified. Technicians test each batch for consistency, using specialized equipment to ensure the coating meets specifications.

Tools like an X-ray fluorescent (XRF) machine are used to confirm the coating's elemental composition and thickness, while a spectrophotometer can verify its color.

Understanding the Trade-offs

Vacuum coating is a powerful technology, but it comes with specific constraints that are critical to understand.

Line-of-Sight Limitations

Processes like sputtering are "line-of-sight," meaning the coating can only deposit on surfaces that have a direct path from the source material. Complex internal geometries or hidden features may not get coated uniformly without specialized fixtures and part rotation.

Process Complexity and Cost

Vacuum coating requires significant capital investment in equipment and a highly controlled environment. It is a batch process that demands skilled operators, making it more expensive than bulk finishing methods like painting or electroplating.

Material and Substrate Compatibility

The choice of coating material and substrate must be compatible. Some substrates, like certain plastics, cannot withstand the temperatures generated during some PVD processes. The adhesion and performance depend heavily on the pairing of the two materials.

Making the Right Choice for Your Application

Selecting the right process depends entirely on your end goal.

- If your primary focus is extreme durability and wear resistance: PVD processes like cathodic arc deposition are ideal for creating hard coatings (e.g., Titanium Nitride) on engine components, cutting tools, and industrial equipment.

- If your primary focus is a decorative or optical finish: Sputtering and other PVD methods can deposit a vast range of materials to create specific colors, reflective surfaces for mirrors, or anti-reflective coatings for ophthalmic lenses.

- If you are coating heat-sensitive materials like plastic: A lower-temperature process like Plasma-Enhanced Chemical Vapor Deposition (PECVD) may be a more suitable choice than a high-temperature PVD method.

By understanding these core principles, you can effectively specify the right vacuum coating process to achieve your desired surface performance.

Summary Table:

| Stage | Key Action | Purpose |

|---|---|---|

| 1. Ablation | Vaporize source material | Create a vapor of coating atoms |

| 2. Transport | Travel through vacuum | Prevent contamination, ensure purity |

| 3. Reaction (Optional) | Introduce reactive gas | Form compounds (e.g., Titanium Nitride) |

| 4. Deposition | Condense onto substrate | Build a dense, uniform, adherent film |

Ready to engineer superior surfaces for your components?

KINTEK specializes in advanced lab equipment and consumables for vacuum coating processes. Whether you are developing durable coatings for cutting tools, decorative finishes for consumer goods, or optical layers for lenses, our expertise and high-quality materials can help you achieve precise, reliable results.

Contact our experts today to discuss how we can support your laboratory's vacuum coating and surface engineering needs.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What are the process capabilities of ICPCVD systems? Achieve Low-Damage Film Deposition at Ultra-Low Temperatures

- Can plasma enhanced CVD deposit metals? Why PECVD is rarely used for metal deposition

- What are different types of thin films? A Guide to Function, Material, and Deposition Methods

- Why does a PECVD vacuum system require both a rotary vane and turbo pump? Ensure High-Purity Coatings

- What is the process of PECVD in semiconductor? Enabling Low-Temperature Thin Film Deposition