At its core, Vacuum Arc Remelting (VAR) is a secondary melting process used to produce metals and alloys with exceptionally high levels of purity and structural integrity. It is not about creating the metal from raw ore, but rather taking an already-formed metal electrode and refining it in a vacuum to remove gases, unwanted elements, and microscopic inconsistencies. This process is essential for creating materials used in the most demanding applications.

The fundamental purpose of VAR is to solve the problems of contamination and structural defects inherent in conventional melting. By remelting an alloy under a high vacuum, it systematically removes impurities and controls the solidification process to create a near-perfect final ingot.

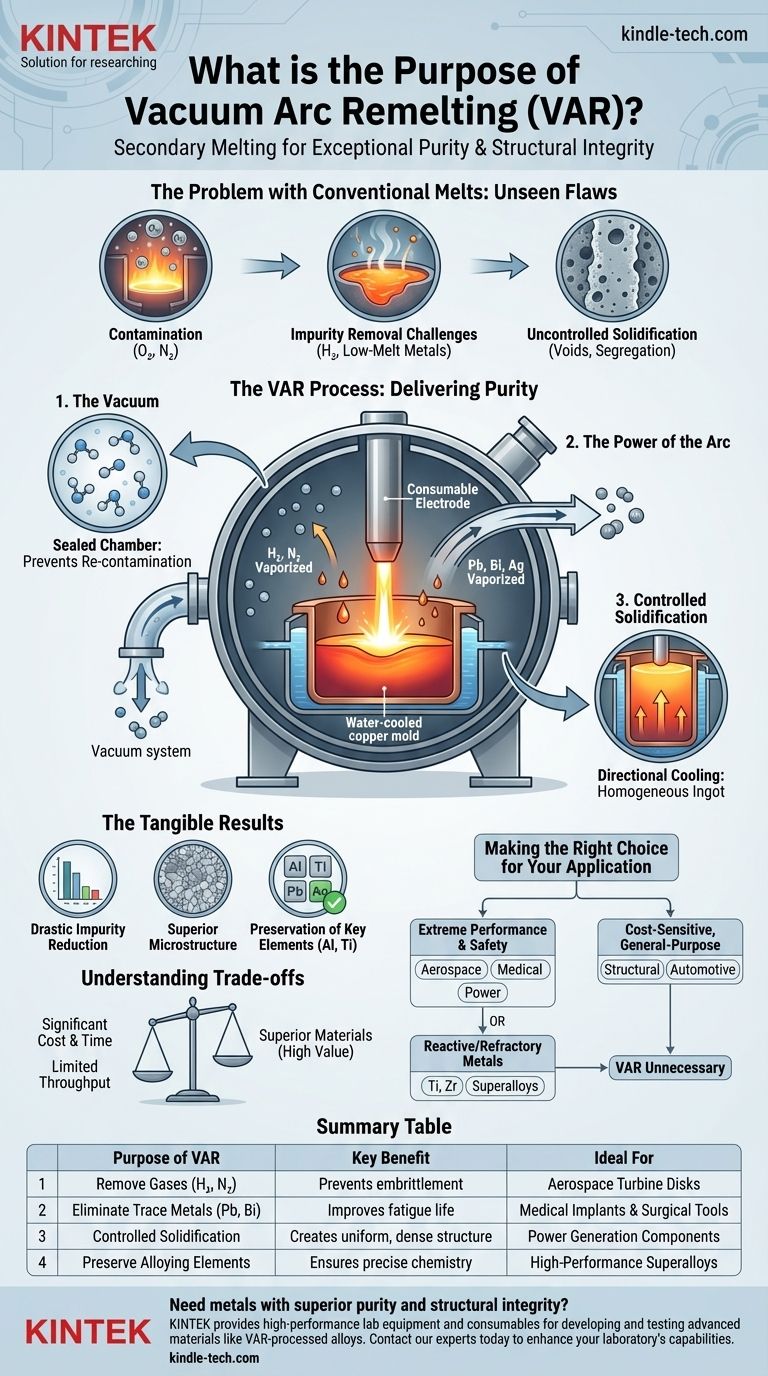

The Problem with Conventional Melts: Unseen Flaws

To understand why VAR is necessary, you must first understand the limitations of a primary melt, where metal is first produced in a standard furnace.

The Inevitability of Contamination

Even in a well-controlled primary melting process, the molten metal is exposed to the atmosphere and the refractory lining of the furnace. This introduces impurities like oxygen and nitrogen, which get trapped as the metal solidifies.

The Challenge of Impurity Removal

Primary melting struggles to remove certain undesirable elements. Gaseous elements like hydrogen become dissolved in the liquid metal, while trace metals with low melting points (like lead or bismuth) can remain, negatively impacting the final properties.

Uncontrolled Solidification

When a large batch of metal cools in a conventional mold, it solidifies from the outside-in. This non-uniform cooling can trap impurities and create internal voids and an inconsistent grain structure, known as segregation. These act as weak points in the final material.

How Vacuum Arc Remelting Delivers Purity

VAR is a systematic, highly-controlled solution to these problems. It takes a solid electrode of the alloy to be refined and uses it as a consumable component in a vacuum furnace.

The Role of the Vacuum

The entire process takes place inside a sealed, high-vacuum chamber. Removing the air is the critical first step, as it prevents re-contamination of the highly reactive molten metal by oxygen and nitrogen from the atmosphere.

The Power of the Arc

An electric arc is struck between the bottom of the electrode and a small amount of starting material in a water-cooled copper mold. The intense heat of the arc (which can exceed the melting point of even refractory metals) progressively melts the tip of the electrode, one droplet at a time.

As these droplets form and fall, they are exposed to the vacuum. This exposure allows dissolved gases like hydrogen and nitrogen to be pulled out, while low-boiling-point metallic impurities (lead, bismuth, silver) are vaporized and removed.

The Importance of Controlled Solidification

The molten droplets collect in the water-cooled copper mold below. Because the mold is actively cooled, the metal solidifies in a highly controlled, directional manner from the bottom up. This process pushes any remaining impurities upward into the still-molten pool at the top, resulting in a solid ingot with exceptional chemical and structural homogeneity.

The Tangible Results: What VAR Achieves

The result of the VAR process is an ingot that is chemically purer and structurally superior to the starting electrode.

Drastic Reduction in Impurities

VAR is highly effective at reducing the content of harmful gases and low-melting-point metals. The final product has significantly lower levels of hydrogen, lead, and other elements that can cause embrittlement or reduce fatigue life.

Superior Microstructure

The controlled, directional solidification creates a dense, uniform ingot free from the porosity and segregation common in conventional castings. This leads to vastly improved and more predictable mechanical properties like strength, ductility, and fatigue resistance.

Preservation of Key Alloying Elements

In a conventional furnace, reactive and beneficial alloying elements like aluminum and titanium can be lost to oxidation. In the VAR vacuum, these elements are protected, ensuring the final alloy chemistry is precisely on target and its intended properties are achieved.

Understanding the Trade-offs

While VAR produces superior materials, it is not a universal solution. Its application comes with specific considerations.

Significant Cost and Time

VAR is a secondary, value-added process. It requires specialized, expensive equipment and adds a significant amount of time and energy cost to production. It is therefore reserved for high-value materials where performance justifies the expense.

Limited Throughput

Compared to primary melting processes that can produce many tons at once, VAR is a batch process that refines a single ingot at a time. This makes it unsuitable for high-volume, commodity-grade metal production.

Not a Cure-All for Impurities

VAR is most effective at removing elements that have a higher vapor pressure than the base metal (meaning they boil off more easily). It is less effective at removing impurities with very low vapor pressures that remain stable in the melt.

Making the Right Choice for Your Application

Choosing a VAR-processed material is a decision driven entirely by the performance and reliability requirements of the final component.

- If your primary focus is extreme performance and safety (aerospace, medical, power generation): VAR is often non-negotiable for critical components like turbine disks, landing gear, or surgical implants where material failure would be catastrophic.

- If your primary focus is working with reactive or refractory metals (titanium, zirconium, superalloys): VAR is a standard and essential step to control the metal's chemistry and prevent the formation of brittle compounds.

- If your primary focus is cost-sensitive, general-purpose applications (structural beams, automotive bodies): VAR is almost certainly unnecessary, as the performance gains do not justify the significant increase in material cost.

Ultimately, vacuum arc remelting is a powerful tool for achieving metallurgical perfection when performance and reliability cannot be compromised.

Summary Table:

| Purpose of VAR | Key Benefit | Ideal For |

|---|---|---|

| Remove Gases (H₂, N₂) | Prevents embrittlement | Aerospace Turbine Disks |

| Eliminate Trace Metals (Pb, Bi) | Improves fatigue life | Medical Implants & Surgical Tools |

| Controlled Solidification | Creates uniform, dense structure | Power Generation Components |

| Preserve Alloying Elements | Ensures precise chemistry | High-Performance Superalloys |

Need metals with superior purity and structural integrity for your critical applications? KINTEK specializes in providing high-performance lab equipment and consumables essential for developing and testing advanced materials like VAR-processed alloys. Our solutions support the stringent requirements of aerospace, medical, and energy sectors. Contact our experts today to discuss how we can enhance your laboratory's capabilities and ensure your materials meet the highest standards of performance and reliability.

Visual Guide

Related Products

- Vacuum Arc Induction Melting Furnace

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What is the VAR melting process? The Ultimate Guide to Vacuum Arc Remelting

- What is the remelting process? Achieve Ultimate Purity and Performance for High-Strength Alloys

- What is the vacuum arc remelting process? Producing Ultra-Pure, High-Performance Metal Alloys

- How does vacuum arc remelting work? Achieve Ultra-Clean, High-Performance Metal Alloys

- What is the benefit of vacuum arc remelting? Achieve Superior Metal Purity and Structural Integrity