At its core, a muffle furnace's performance is defined by its refractory materials. The most common choices for the insulating lining are high-strength alumina (Al₂O₃), silicon carbide (SiC), and lightweight ceramic fibers, often formed into durable bricks. These materials are selected for their ability to withstand extreme temperatures while ensuring uniform and stable process conditions.

The specific refractory material used in a muffle furnace is not just a detail—it is the critical factor that dictates the furnace's heating speed, energy efficiency, chemical compatibility, and suitability for high-purity applications.

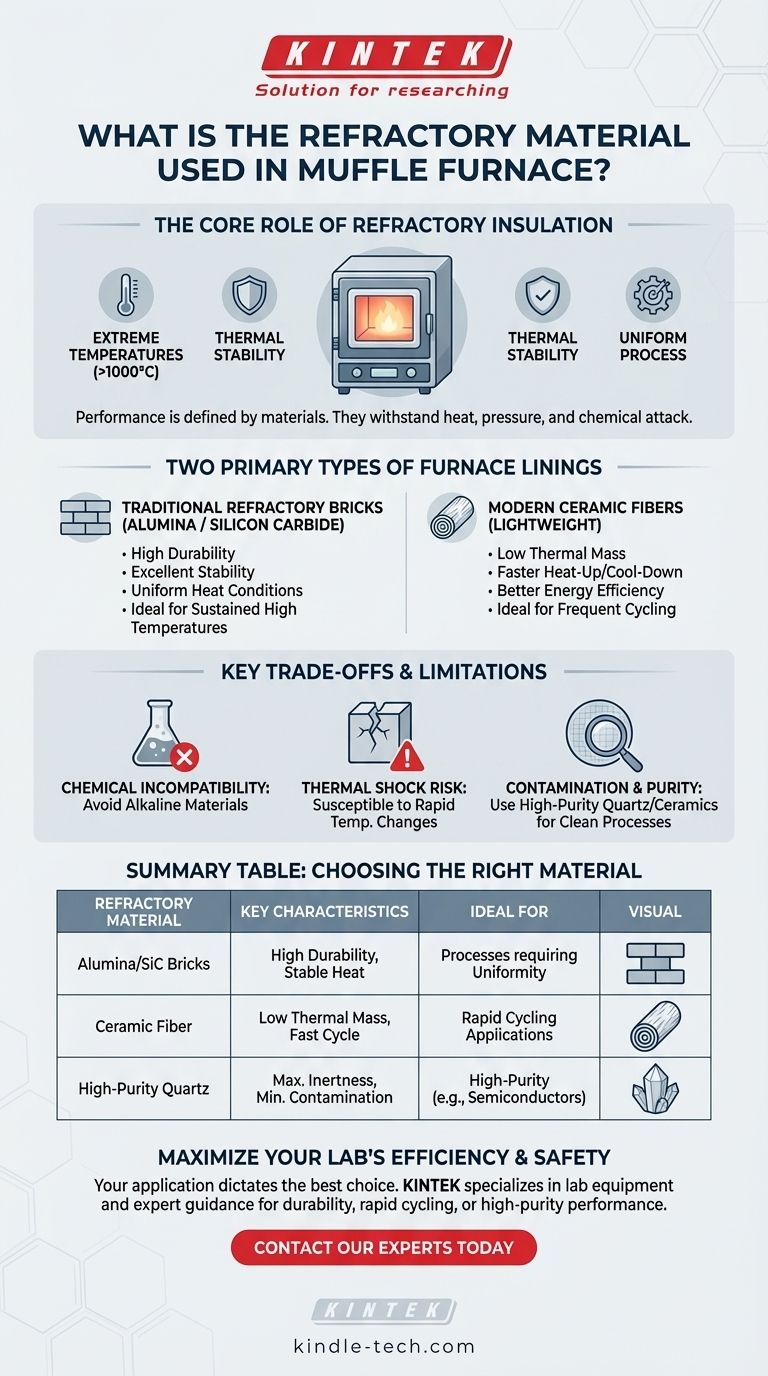

The Role of Refractory Insulation

Why Special Materials Are Necessary

At temperatures above 200°C, standard materials begin to degrade, deform, or fail. Muffle furnaces operate at much higher temperatures, often exceeding 1000°C, which demands the use of specialized refractory materials.

Defining "Refractory" Properties

The term refractory describes a class of materials that are exceptionally resistant to heat, pressure, and chemical attack. Key properties include an extremely high melting point, thermal stability, and resistance to wear and deformation under heat.

The Two Primary Types of Furnace Linings

Muffle furnaces are generally classified into two categories based on their primary insulation material. This choice fundamentally alters the furnace's performance characteristics.

Traditional Refractory Bricks

Furnaces lined with dense, hard bricks made from materials like high-strength alumina or silicon carbide are the traditional standard. These materials offer excellent durability and create highly stable and uniform temperature conditions inside the chamber.

Modern Ceramic Fibers

A more modern approach uses lightweight ceramic fiber insulation. This material has lower thermal mass, allowing the furnace to heat up and cool down much faster. This often results in better energy efficiency for processes that require frequent cycles.

Understanding the Trade-offs and Limitations

The choice of refractory material involves a balance of performance, durability, and compatibility. Understanding these trade-offs is crucial for safe and effective operation.

Chemical Incompatibility

Certain substances can chemically attack and degrade the refractory lining. Alkaline materials, for example, should never be used to melt or process samples inside a muffle furnace, as they can damage the chamber.

Risk of Thermal Shock

While excellent at handling sustained high temperatures, some refractory ceramics can be susceptible to thermal shock—cracking caused by rapid temperature changes. Materials like quartz, sometimes used for high-purity applications, are particularly vulnerable.

Contamination and Purity

For high-purity work, such as in the semiconductor industry, the refractory material itself can be a source of contamination. In these cases, specialized materials like high-purity quartz or ceramic are used for internal components to ensure the process remains clean.

Prohibited Materials

For safety and to protect the furnace lining, you should never place flammable, explosive, or strongly corrosive materials inside. Additionally, materials that can easily melt or deform at low temperatures may damage the furnace floor.

How to Apply This to Your Process

Your specific application will determine which type of furnace and refractory material is most suitable for your work.

- If your primary focus is durability and temperature stability: A furnace lined with traditional alumina or silicon carbide firebricks is a robust and reliable choice.

- If your primary focus is rapid cycling and energy efficiency: A furnace with a modern ceramic fiber lining will provide faster heat-up and cool-down times.

- If your primary focus is high-purity applications: You need to ensure the furnace uses materials like quartz or high-purity ceramics that will not contaminate your samples.

By understanding the properties of its refractory lining, you can maximize the performance and lifespan of your muffle furnace.

Summary Table:

| Refractory Material | Key Characteristics | Ideal For |

|---|---|---|

| Alumina / Silicon Carbide Bricks | High durability, excellent temperature stability | Processes requiring uniform, stable heat |

| Ceramic Fiber | Low thermal mass, fast heat-up/cool-down, energy-efficient | Rapid cycling applications |

| High-Purity Quartz/Ceramics | Maximum chemical inertness, minimal contamination | High-purity applications (e.g., semiconductors) |

Maximize your lab's efficiency and safety with the right muffle furnace. The refractory lining is critical for your application's success, impacting temperature stability, heating speed, and sample purity. At KINTEK, we specialize in lab equipment and consumables, providing expert guidance to help you select the perfect furnace for your specific processes—whether you need durability, rapid cycling, or high-purity performance.

Contact our experts today to discuss your requirements and ensure you get the most reliable and efficient solution for your laboratory needs.

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Graphite Vacuum Continuous Graphitization Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

People Also Ask

- What is the principle of rotary kiln? Mastering Continuous Thermal Processing

- What are the equipment for pyrolysis laboratory? Choosing the Right Reactor for Your Research

- What are the types of pyrolysis reactors used in industry? Choose the Right Technology for Your Product

- What is the purpose of a calciner? Boost Efficiency in High-Temperature Processing

- What are the products of pyrolysis of wood? A Guide to Biochar, Bio-oil, and Syngas Yields