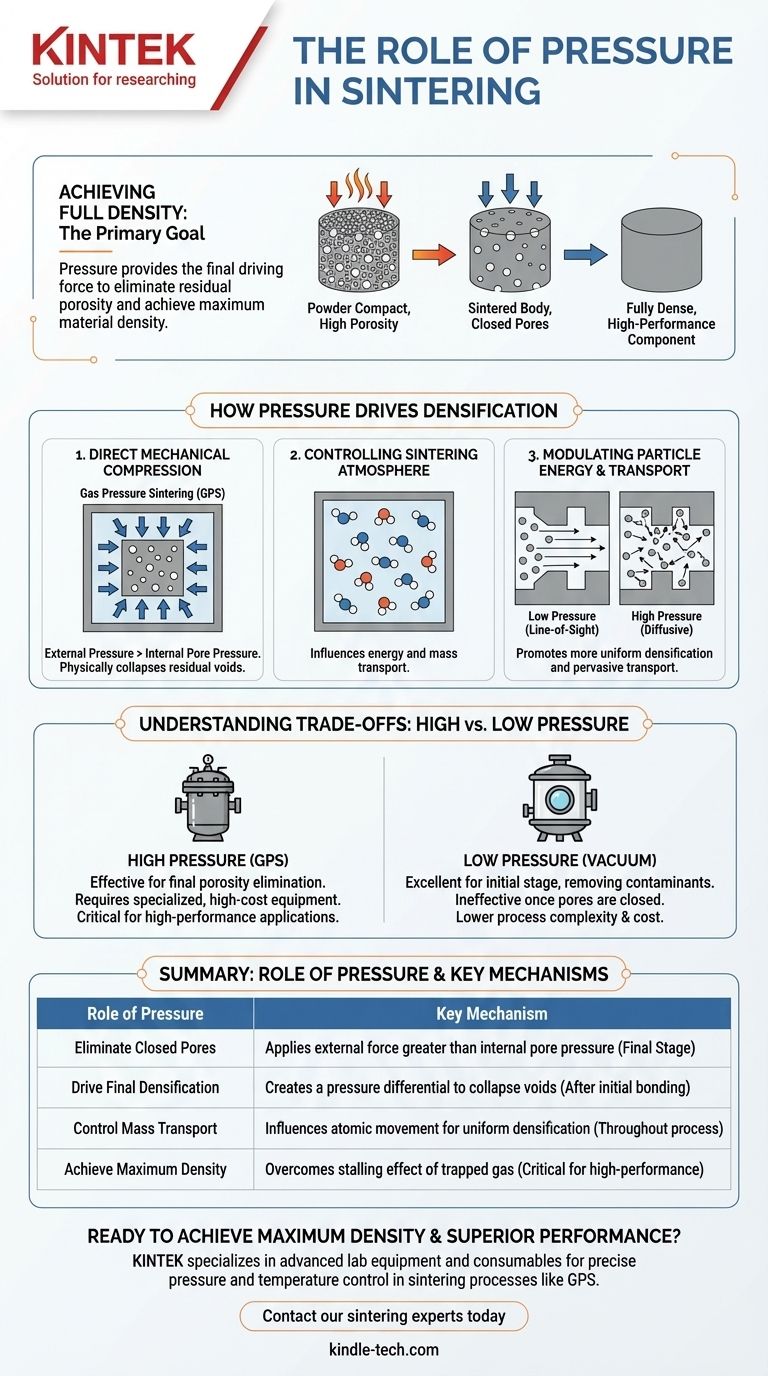

In sintering, the primary role of pressure is to provide the final driving force needed to eliminate residual porosity and achieve maximum material density. After initial sintering bonds particles together and leaves only isolated, closed pores, an external gas pressure is applied to physically compress these voids, creating a fully dense, high-performance component.

Pressure is more than a simple mechanical force; it is a critical control parameter. By manipulating the pressure of the surrounding gas atmosphere, you can not only physically collapse pores but also fundamentally influence the energy and movement of atoms to enhance the densification process.

The Fundamental Goal: Achieving Full Density

Sintering is the process of compacting and forming a solid mass of material by heat and/or pressure without melting it to the point of liquefaction. The goal is to create a dense, coherent object from a powder.

The Problem of Closed Pores

In the initial stages of sintering, particles fuse together, and pores between them form an interconnected network that allows trapped gas to escape. As densification proceeds, these channels pinch off, leaving behind isolated, closed pores.

At this stage, further densification slows dramatically. The gas trapped inside these pores exerts an internal pressure that counteracts the sintering forces, effectively halting the process before full density is reached.

How Pressure Drives Densification

Applying external pressure is the key to overcoming the obstacle of closed pores and completing the densification journey. This is achieved through several mechanisms.

Direct Mechanical Compression

The most straightforward function of pressure is mechanical force. In processes like Gas Pressure Sintering (GPS), the component is heated in a chamber filled with a high-pressure, inert gas.

This external pressure is greater than the internal pressure of the trapped gas within the closed pores. The resulting pressure differential creates a powerful driving force that physically collapses the residual voids, pushing the material to near-theoretical density.

Controlling the Sintering Atmosphere

Pressure also plays a more subtle role by controlling the processing atmosphere. The pressure of the gas in the chamber influences how energy and mass are transported.

At higher gas pressures, atoms and ions traveling through the chamber will collide more frequently with the gas atoms. This is a critical concept seen in related thin-film deposition processes.

Modulating Particle Energy and Transport

These collisions act as a moderating effect. Instead of particles moving in a straight, line-of-sight path, they are scattered and begin to move more diffusively, like a random walk.

While sintering itself doesn't involve deposition, this principle is analogous. A higher-pressure environment can facilitate the transport of material into complex voids and undercuts that might otherwise be hard to fill, promoting more uniform densification. At low pressures, movement is more direct; at high pressures, it becomes more pervasive.

Understanding the Trade-offs

Choosing the right pressure strategy is a balance between achieving desired material properties and managing process complexity. Applying pressure is not a one-size-fits-all solution.

High Pressure vs. Low Pressure

High pressure (as in GPS) is extremely effective for eliminating the final percentage of porosity but requires specialized, high-cost pressure vessels.

Low pressure (vacuum) is excellent for the initial stages of sintering, as it helps remove contaminants and atmospheric gases from the open pore network. However, it is ineffective once pores become closed and isolated.

Process Complexity and Cost

The decision to use a high-pressure sintering step is primarily an economic and engineering one. The equipment needed to safely handle high pressures and temperatures is significantly more complex and expensive than standard atmospheric furnaces.

This additional cost is only justified for high-performance applications where achieving maximum density and eliminating all defects is critical to the component's function and reliability.

Applying Pressure for Your Sintering Goal

Your strategy for using pressure should be dictated by the final properties your component requires.

- If your primary focus is achieving maximum density and mechanical strength: A multi-stage process is best, using vacuum or atmospheric sintering first, followed by a high-pressure step (like GPS) to eliminate final porosity.

- If your primary focus is cost-effective production of less critical parts: Standard atmospheric sintering may be sufficient, accepting a small amount of residual porosity in exchange for lower process cost and complexity.

- If your goal involves coating or filling complex shapes (in a related process): A higher background gas pressure can be beneficial, as it promotes diffusive, non-line-of-sight material transport to ensure complete coverage.

Ultimately, pressure is a powerful and versatile tool for mastering the final microstructure and integrity of your material.

Summary Table:

| Role of Pressure | Key Mechanism | Sintering Stage |

|---|---|---|

| Eliminate Closed Pores | Applies external force greater than internal pore pressure | Final Stage |

| Drive Final Densification | Creates a pressure differential to collapse voids | After initial particle bonding |

| Control Mass Transport | Influences atomic movement for uniform densification | Throughout the process |

| Achieve Maximum Density | Overcomes the stalling effect of trapped gas in pores | Critical for high-performance parts |

Ready to achieve maximum density and superior performance in your materials?

At KINTEK, we specialize in the advanced lab equipment and consumables needed to master sintering processes like Gas Pressure Sintering (GPS). Our solutions are designed for laboratories and manufacturers who require precise control over pressure and temperature to eliminate porosity and produce fully dense, high-integrity components.

Whether you are developing high-performance ceramics, advanced metals, or specialized composites, our expertise can help you optimize your sintering strategy for unparalleled results.

Contact our sintering experts today to discuss how KINTEK's equipment can enhance your material's properties and reliability.

Visual Guide

Related Products

- Cold Isostatic Pressing Machine CIP for Small Workpiece Production 400Mpa

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Electric Split Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

People Also Ask

- What is the process of hot pressing ceramics? Achieve Superior Density and Performance

- Why is a vacuum hot press sintering furnace required for Co-50 mass% Cr alloys? Achieve 96% Relative Density

- Why are high-vacuum diffusion bonding furnaces required for titanium alloys? Ensure High-Strength Multilayer Laminates

- What performance improvements does Ga-LLZO exhibit after HIP treatment? Double Your Ionic Conductivity

- How does a graphite resistance vacuum hot pressing furnace facilitate the densification of hard-to-sinter ZrB2 ceramics?

- What are the key functions of a vacuum hot press sintering furnace? Produce High-Density UN Ceramic Pellets

- How does a high vacuum environment contribute to the hot pressing of Ruthenium? Enhance Purity and Density

- How does Hot Pressing Furnace pressure influence SiC/Cu-Al2O3 composites? Achieve 99.22% Density & Superior Strength