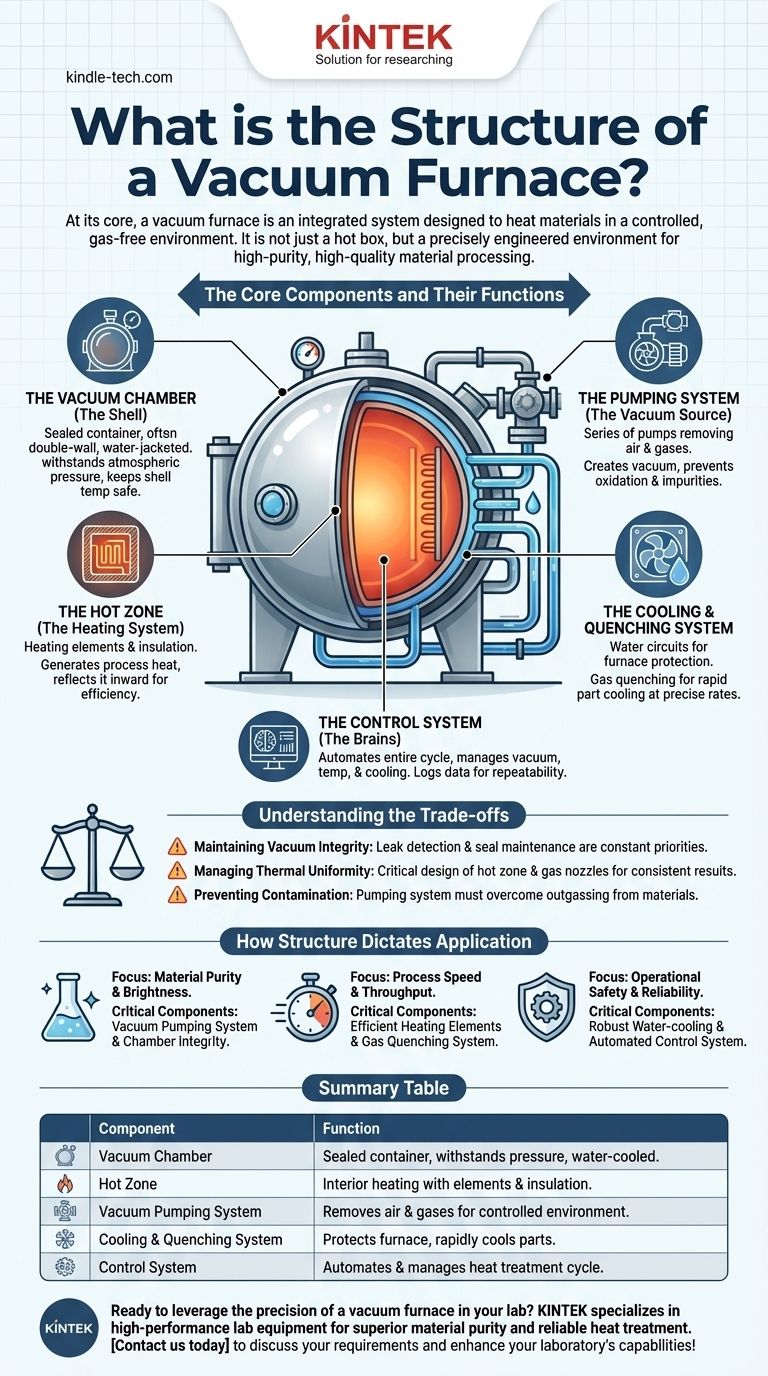

At its core, a vacuum furnace is an integrated system designed to heat materials in a controlled, gas-free environment. Its structure consists of a sealed furnace chamber, a vacuum pumping system to remove air, an internal heating system (the hot zone), a cooling system to protect the furnace and quench the parts, and a sophisticated control system to manage the entire process.

The key takeaway is that a vacuum furnace is not just a hot box, but a precisely engineered environment. Each component works in concert to achieve one primary goal: removing the reactive atmosphere to enable high-purity, high-quality material processing that would be impossible in open air.

The Core Components and Their Functions

To understand a vacuum furnace, you must understand how its primary systems interact. Each part serves a critical function in creating and maintaining the controlled environment required for advanced heat treatment.

The Vacuum Chamber (The Shell)

The vacuum chamber, often called the shell or vessel, is the outer structure that contains the entire process. It is a hermetically sealed container designed to withstand the immense external atmospheric pressure when a vacuum is pulled inside.

Most chambers are a double-wall, water-jacketed design made from high-strength steel. This water cooling is essential to keep the shell temperature safe while the interior reaches extreme temperatures, protecting both the equipment and the operators.

The Hot Zone (The Heating System)

Located inside the vacuum chamber, the hot zone is where the heating takes place. It consists of the heating elements and the insulation package.

The heating elements, often made of graphite or refractory metals, are responsible for generating the required process heat. The surrounding insulation, typically composed of materials like carbon felt or metallic heat shields, reflects this heat inward toward the workload, ensuring thermal efficiency and protecting the cooled chamber walls.

The Pumping System (The Vacuum Source)

The vacuum system is the heart of the furnace's unique capability. It is a series of pumps designed to remove air and other gases from the chamber before and during the heating cycle.

This system creates the vacuum, preventing oxidation and removing impurities that could otherwise compromise the material being treated. The quality of the vacuum directly impacts the purity and final properties of the end product.

The Cooling & Quenching System

This system serves two purposes: protecting the furnace and rapidly cooling the workload. As mentioned, water cooling circuits continuously run through the furnace shell to prevent it from overheating.

For cooling the parts, a process known as quenching, high-pressure inert gas like nitrogen or argon is often blasted into the chamber. This gas quenching system must cool the material at a precise rate to achieve the desired metallurgical properties.

The Control System (The Brains)

The control system is the furnace's nerve center. It integrates all other components, automating the entire treatment cycle from a single interface.

This system precisely manages vacuum levels, temperature ramp rates, soak times, and cooling cycles. Modern control systems log all process data, ensuring repeatability, traceability, and quality control.

Understanding the Trade-offs

While powerful, the structure of a vacuum furnace presents specific operational challenges. Success depends on understanding the delicate balance between its integrated systems.

Maintaining Vacuum Integrity

The entire process relies on the chamber's ability to remain sealed. Any leak in the shell, door seals, or connection points will degrade the vacuum, introduce contaminants like oxygen, and ruin the process. Leak detection and seal maintenance are constant operational priorities.

Managing Thermal Uniformity

Achieving a perfectly uniform temperature across the entire workload is a significant challenge. The design of the hot zone, including the placement of heating elements and gas cooling nozzles, is critical. Poor uniformity can lead to inconsistent material properties.

Preventing Contamination

The goal of a vacuum is purity. However, materials inside the furnace, including the workload itself, can release trapped gases when heated—a process called outgassing. The pumping system must be powerful enough to overcome this and maintain the required vacuum level throughout the cycle.

How Structure Dictates Application

The specific design and capabilities of a furnace's components determine its ideal use. When evaluating or operating a vacuum furnace, consider your primary goal.

- If your primary focus is material purity and brightness: Your most critical components are the vacuum pumping system and the chamber's leak-tight integrity.

- If your primary focus is process speed and throughput: The efficiency of the heating elements and the power of the gas quenching system are paramount.

- If your primary focus is operational safety and reliability: The robustness of the water-cooling circuits and the sophistication of the automated control system are key.

By understanding this architecture, you can move from simply using the equipment to truly mastering the powerful capabilities of vacuum heat treatment.

Summary Table:

| Component | Primary Function |

|---|---|

| Vacuum Chamber (Shell) | Sealed container that withstands atmospheric pressure; often water-cooled. |

| Hot Zone | Interior heating system with elements and insulation for thermal efficiency. |

| Vacuum Pumping System | Removes air and gases to create a controlled, reactive-atmosphere-free environment. |

| Cooling & Quenching System | Protects the furnace and rapidly cools parts using water circuits and gas quenching. |

| Control System | Automates and manages the entire heat treatment cycle for precision and repeatability. |

Ready to leverage the precision of a vacuum furnace in your lab? KINTEK specializes in high-performance lab equipment, including vacuum furnaces designed for superior material purity and reliable heat treatment processes. Our experts can help you select the right system to meet your specific application needs. Contact us today to discuss your requirements and enhance your laboratory's capabilities!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What is the use of a heat treatment furnace? Transform Material Properties for Superior Performance

- What are the specific functions of a vacuum oven in VRFB electrode preparation? Enhance Carbon Paper Performance

- What applications are brazing used in? Joining Metals for Aerospace, Automotive & Medical Devices

- What are the stages of sintering? A Guide to Mastering the Powder-to-Part Process

- What is the high temperature of a vacuum furnace? Pushing Thermal Limits for Advanced Materials

- What is the temperature of an industrial furnace? It's all about your process and material.

- What is the rule of thumb for sintering temperature? Achieve the Perfect Balance for Your Materials

- Why is a high vacuum brazing furnace necessary for nickel-based alloys? Achieve Oxidation-Free, High-Strength Joints