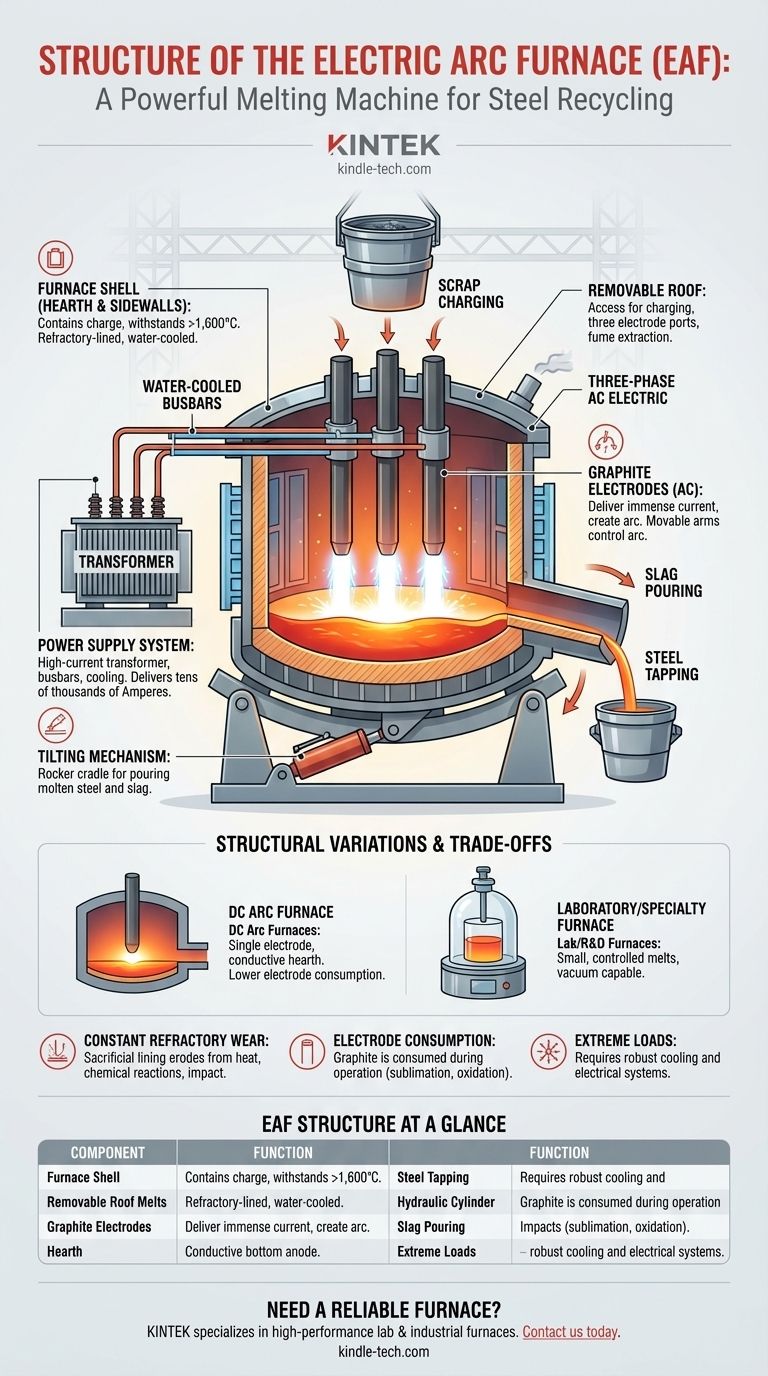

At its core, an electric arc furnace (EAF) is a powerful melting machine with a relatively simple structure. It consists of a robust, refractory-lined steel shell to contain the charge, a removable roof that provides access and holds the electrodes, and massive graphite electrodes that deliver the electricity needed to create an arc and melt the metal. The entire assembly is mounted on a tilting mechanism to pour out the finished molten steel.

The electric arc furnace is best understood not just as a container, but as a dynamic system designed for a single purpose: to safely withstand and channel immense electrical energy into thermal energy to melt scrap metal at extreme temperatures.

The Core Components of an EAF

The most common industrial EAF is a three-phase AC furnace. Its structure is a direct reflection of its function: charging, melting, and tapping.

The Furnace Shell (Hearth and Sidewalls)

The main body of the furnace is a large, cylindrical, or "d-shape" steel shell. The bottom of the shell is known as the hearth.

This entire shell is lined with refractory bricks—heat-resistant materials like magnesia-carbon—that can withstand the extreme temperatures of molten steel, which exceed 1,600°C (3,000°F).

In modern furnaces, the upper sidewalls and roof often incorporate water-cooled panels to manage thermal stress and reduce refractory wear.

The Roof

The furnace roof is a removable, refractory-lined cover. It typically swings or pivots to the side to allow a large scrap bucket to charge (load) the furnace from above.

Crucially, the roof has three circular holes through which the electrodes are lowered into the furnace. It may also have a "fourth hole" for fume and gas extraction.

The Electrodes and Electrode System

The heart of the furnace is its set of three massive graphite electrodes. These rods, which can be over 2 feet in diameter, conduct the enormous electrical current needed for melting.

The electrodes are mounted on vertical masts with movable arms that can raise, lower, and swing them precisely. This system allows operators to control the arc's length and position.

The Power Supply System

An EAF requires a dedicated high-power electrical system. This includes a large transformer to step down the voltage from the grid and provide the extremely high current (tens of thousands of amperes) the electrodes need.

Heavy, often water-cooled copper busbars or cables connect the transformer to the electrode arms, delivering the power to the furnace.

The Tilting Mechanism

The entire furnace shell is mounted on a "rocker" or cradle. This allows the vessel to be tilted forward by a hydraulic or electric drive system.

This tilting action is used for two main purposes: pouring the finished molten steel into a ladle through a tap-hole, and tilting backward to pour off the lighter layer of slag (impurities).

Understanding Structural Variations

While the three-phase AC furnace is the standard for steelmaking, it's important to recognize other related designs mentioned in technical literature.

DC Arc Furnaces

Direct-current (DC) furnaces are a significant alternative. They typically use a single, large graphite electrode in the center and a conductive bottom lining (anode) to complete the circuit through the metal charge itself. This can offer advantages like lower electrode consumption.

Laboratory & Specialty Furnaces

References to a single-electrode furnace in a "water-cooled stainless steel Bell Jar" describe a much smaller, specialized laboratory or R&D furnace. Its structure is optimized for small, controlled melts, often under vacuum, not for high-volume industrial production.

Distinguishing from Induction Furnaces

An induction furnace is an entirely different technology often confused with an EAF. It does not use electrodes or an arc. Instead, it uses a copper coil to create a powerful magnetic field that induces electrical currents within the metal itself, generating heat through resistance.

The Inherent Trade-offs of the EAF Design

The EAF's structure is a masterclass in managing extreme conditions, but this comes with necessary compromises and operational challenges.

Constant Refractory Wear

The refractory lining is a sacrificial component. The intense heat of the arc, chemical reactions with the slag, and the physical impact of charging scrap mean the lining erodes and must be regularly repaired or replaced, creating downtime.

Electrode Consumption

The graphite electrodes are not permanent. They are gradually consumed during operation due to sublimation at the arc tip and oxidation. This consumption is a significant and continuous operational cost.

Extreme Thermal and Electrical Loads

The entire structure, from the water-cooled panels to the power cables, must be engineered to handle massive thermal and electrical loads. Failure in the cooling systems or electrical connections can be catastrophic.

Choosing the Right Framework for Your Goal

Understanding the EAF's structure is key to evaluating its role in the metals industry. Your specific interest dictates which aspects are most important.

- If your primary focus is large-scale steel production: Concentrate on the three-phase AC furnace design, as its structure is optimized for high-volume, rapid scrap melting.

- If your primary focus is operational efficiency: The design of DC furnaces, with their single electrode and conductive hearth, is the key structural difference to analyze.

- If your primary focus is research or specialty alloy development: A smaller, vacuum-capable single-electrode "bell jar" furnace provides the controlled environment needed, a structure fundamentally different from production EAFs.

Ultimately, the structure of an electric arc furnace is a purpose-built solution to the challenge of withstanding and controlling a contained lightning storm to efficiently recycle steel.

Summary Table:

| Component | Function | Key Features |

|---|---|---|

| Furnace Shell | Contains the charge and withstands extreme heat | Refractory-lined, water-cooled panels |

| Roof | Provides access for charging and electrode placement | Removable, refractory-lined, with electrode ports |

| Electrodes | Deliver electrical current to create the arc | Graphite rods, movable arms for precise control |

| Power Supply | Provides high current for melting | Transformer, busbars, and cooling systems |

| Tilting Mechanism | Enables pouring of molten steel and slag removal | Hydraulic or electric drive system |

Need a reliable furnace for your lab or industrial process? KINTEK specializes in high-performance lab equipment, including furnaces tailored for research, testing, and production. Whether you're melting metals, heat-treating materials, or developing new alloys, our solutions deliver precision, durability, and efficiency. Contact us today to discuss your specific requirements and discover how KINTEK can enhance your operations!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- How to clean a tube furnace? A Step-by-Step Guide for Safe and Effective Maintenance

- How does a quartz tube facilitate fractional condensation in a horizontal tube vacuum gasification furnace? Expert Guide

- How do a quartz tube reactor and atmosphere furnace collaborate in Co@NC pyrolysis? Master Precision Synthesis

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.

- How does a high-temperature tube furnace facilitate the phase transformation of alumina products? Master Thermal Control