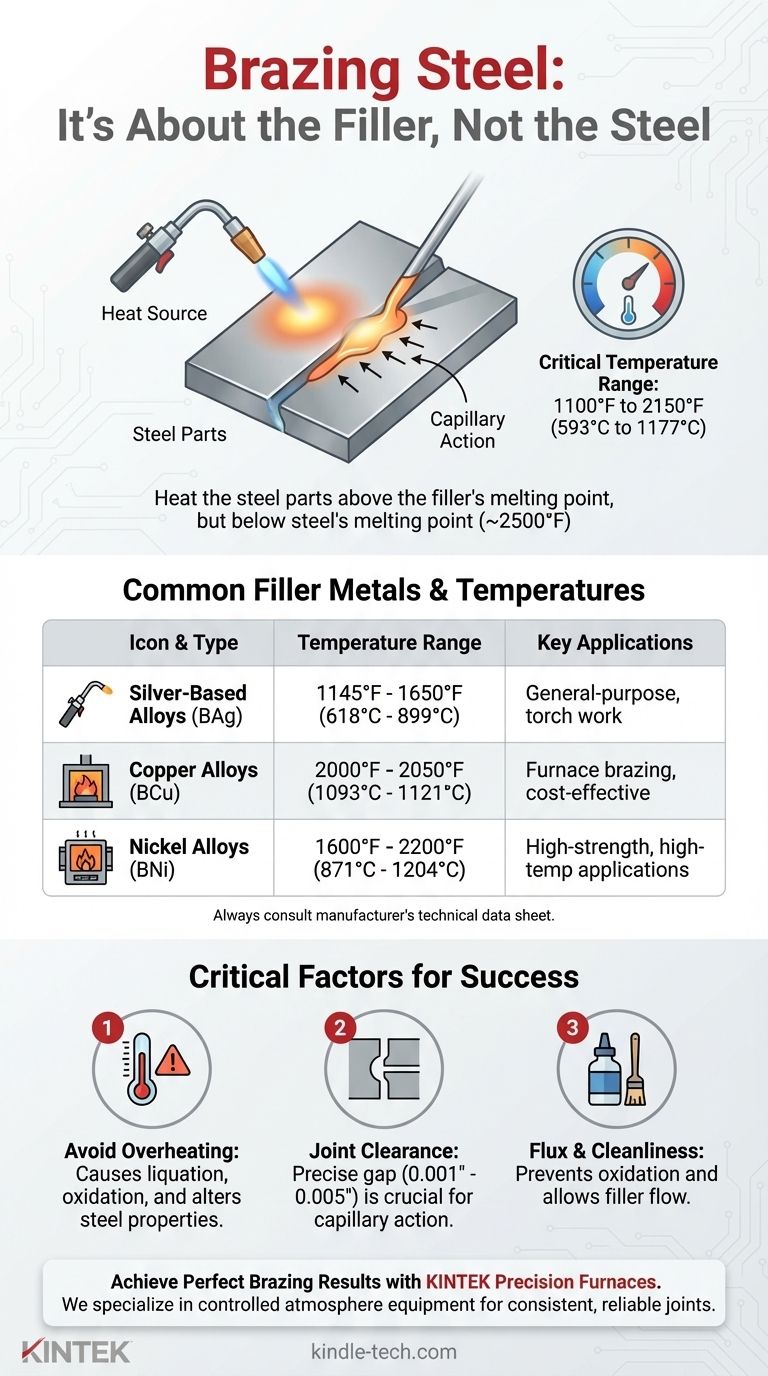

In brazing steel, the critical temperature is not determined by the steel, but by the specific filler metal you use. The process involves heating the steel parts to a temperature that is above the melting point of your chosen brazing alloy, but always below the melting point of the steel itself. For steel, this temperature typically falls within a broad range of 1100°F (593°C) to 2150°F (1177°C), dictated entirely by the filler.

The core principle of brazing is to heat the base metals—the steel parts—until they are hot enough to melt the filler metal upon contact. The goal is to draw the molten filler into the joint through capillary action, creating a strong metallurgical bond without melting the steel.

The Principle: It's About the Filler Metal, Not the Steel

What Defines Brazing?

Brazing is a joining process that occurs at temperatures above 840°F (450°C). Crucially, this temperature must be lower than the solidus temperature (the point at which it begins to melt) of the base metals being joined.

For steel, which melts around 2500°F (1370°C), this provides a very wide window for brazing to occur.

The Filler Metal's "Working Range"

Every brazing alloy has a "working range" defined by two temperatures:

- Solidus: The temperature at which the alloy begins to melt.

- Liquidus: The temperature at which the alloy is fully liquid.

The ideal brazing temperature is slightly above the liquidus temperature. This ensures the alloy is fluid enough to flow quickly and completely into the joint.

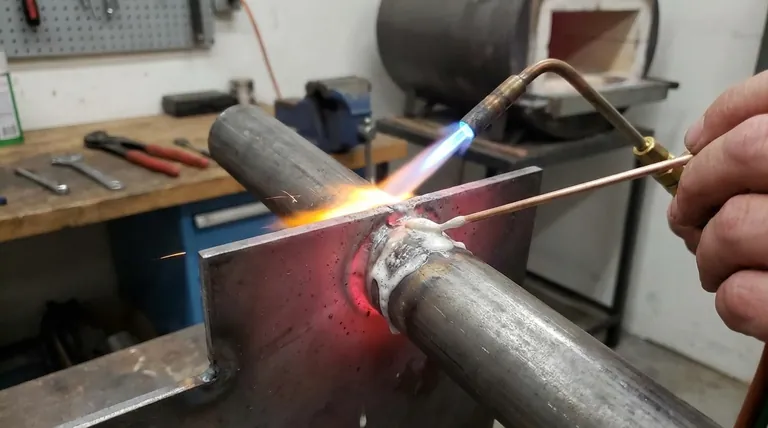

How Heat and Capillary Action Work

You must heat the steel parts of the assembly broadly and uniformly. When the steel reaches the correct temperature, you touch the filler rod to the joint. The heat from the steel melts the rod, and the molten alloy is pulled into the tight space between the parts.

Heat draws the filler. If one part is hotter than the other, the filler will flow toward the hotter area, resulting in an incomplete joint.

Common Filler Metals for Steel and Their Temperatures

The alloy you select depends on the strength requirements, service conditions, and parent metals. Always consult the manufacturer's technical data sheet for precise temperature recommendations.

Silver-Based Alloys (BAg series)

These are the most common alloys for general-purpose steel brazing due to their strength, ductility, and lower melting temperatures.

They typically braze in the range of 1145°F to 1650°F (618°C to 899°C). Their lower heat requirement makes them easier to work with, especially with a torch.

Copper Alloys (BCu series)

Pure copper is an excellent filler for brazing steel, particularly in controlled-atmosphere furnace brazing. It is very fluid and cost-effective.

The typical brazing temperature for pure copper is 2000°F to 2050°F (1093°C to 1121°C).

Copper-Phosphorus Alloys (BCuP series)

Do not use these alloys for brazing steel or other ferrous metals. The phosphorus can react with the iron in the steel to form brittle phosphides at the joint interface, leading to catastrophic joint failure.

Nickel and Cobalt Alloys (BNi, BCo series)

Used for high-performance applications, especially on stainless steel, where superior strength, corrosion resistance, and high-temperature service are required.

These alloys require very high temperatures, often from 1600°F to 2200°F (871°C to 1204°C), and are almost exclusively used in vacuum or atmosphere-controlled furnaces.

Understanding the Trade-offs and Critical Factors

Achieving the correct temperature is necessary, but not sufficient. Several other factors are just as important for success.

The Danger of Overheating

Exceeding the recommended temperature can cause the filler metal's components to separate (liquation), damage the flux, heavily oxidize the steel, or even alter the steel's metallurgical properties (e.g., losing its heat treat).

The Problem with Underheating

If the steel is not hot enough, the filler metal will fail to melt and flow properly. It may clump on the surface or fail to penetrate the joint, resulting in a bond with no structural strength.

The Role of Flux and Cleanliness

The steel parts must be mechanically or chemically cleaned before heating. At temperature, a coating of flux is required to prevent the steel from oxidizing, which would block the flow of the filler metal. The flux also helps dissolve any remaining surface oxides.

Joint Clearance is Non-Negotiable

Brazing relies on capillary action, which only works if the gap between the two steel parts is precise. For most alloys, this is a very tight clearance of 0.001 to 0.005 inches (0.025 to 0.127 mm). Too loose or too tight, and the joint will fail.

How to Achieve a Successful Braze

Your choice of filler metal is the starting point that dictates the entire process.

- If your primary focus is general repair or accessible fabrication: Choose a cadmium-free silver alloy (BAg series), which offers excellent strength and a forgiving, low-temperature application range suitable for torch brazing.

- If your primary focus is high-strength or high-temperature service: Look to nickel (BNi) or pure copper (BCu) alloys, but recognize these demanding processes typically require a furnace.

- If you are new to brazing: Your most valuable tool is the technical data sheet for your chosen filler metal. It will specify the exact solidus/liquidus temperatures and recommended flux.

By focusing on the specific requirements of your filler metal, you move from guesswork to a predictable and reliable joining process.

Summary Table:

| Filler Metal Type | Typical Brazing Temperature Range (°F) | Typical Brazing Temperature Range (°C) | Key Applications |

|---|---|---|---|

| Silver-Based Alloys (BAg) | 1145°F - 1650°F | 618°C - 899°C | General-purpose steel brazing, torch work |

| Copper Alloys (BCu) | 2000°F - 2050°F | 1093°C - 1121°C | Furnace brazing, cost-effective joints |

| Nickel Alloys (BNi) | 1600°F - 2200°F | 871°C - 1204°C | High-strength, high-temperature applications |

Achieve Perfect Brazing Results with KINTEK

Are you looking to optimize your steel brazing process? Whether you're working with silver alloys for general fabrication or nickel alloys for high-temperature applications, having the right equipment is crucial for success.

KINTEK specializes in precision lab furnaces and heating equipment designed specifically for controlled brazing processes. Our solutions help you maintain exact temperatures, ensure uniform heating, and achieve strong, reliable joints every time.

We serve laboratories and manufacturing facilities that require consistent, repeatable results in their metal joining operations. Let us help you select the perfect furnace for your specific filler metals and application requirements.

Contact us today to discuss how our brazing equipment can improve your joint quality and process efficiency: Get in Touch

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- Why must a vacuum furnace environment be employed during WEAM? Ensure Beam Integrity and Material Purity

- What is the purpose of using high-temperature vacuum furnaces for annealing titanium dioxide? Optimize Bioactivity

- What role does a vacuum oven play in the drying process of ZIF-67 precursors? Ensure Purity for High-Quality Synthesis

- Is heat Cannot travel in a vacuum True or false? Discover How Heat Crosses the Void of Space

- Can you determine the temperature of a vacuum? Unpacking the Physics of 'Empty' Space

- What is the function of a vacuum drying oven in Starbon preparation? Preserving Pore Integrity and Surface Area

- What is the primary function of a vacuum oven in FEP membrane prep? Ensure Defect-Free Fiber Production

- How does the cooling rate control of a furnace influence slow-cooled solid-state electrolytes? Achieve Crystal Perfection