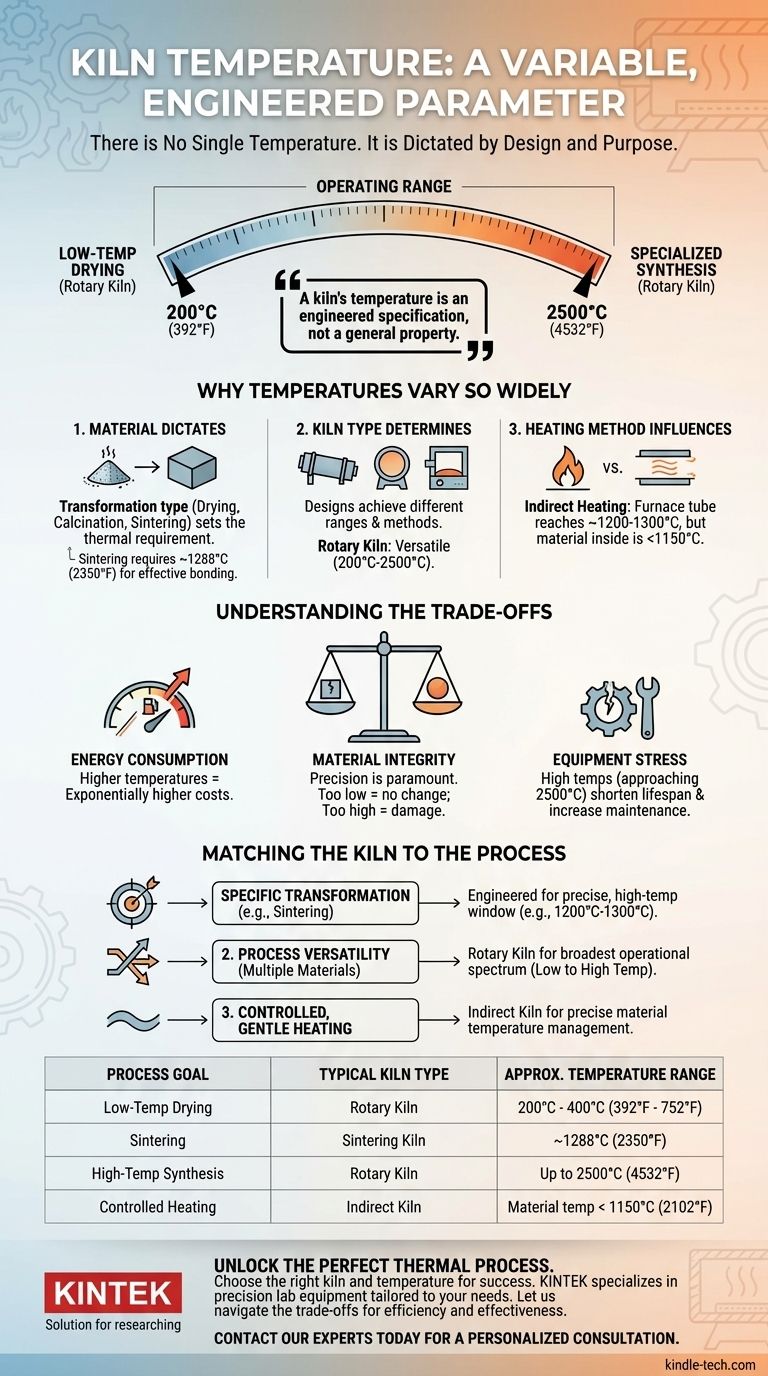

There is no single temperature for a kiln. The operating temperature of a kiln is not a fixed number but a highly variable parameter dictated by its design and industrial purpose. A versatile rotary kiln can operate anywhere from 200°C (392°F) for low-temperature drying up to 2500°C (4532°F) for specialized material synthesis, while a specific sintering kiln may be designed to operate at a maximum of 1288°C (2350°F).

A kiln's temperature is an engineered specification, not a general property. It is determined entirely by the physical or chemical transformation required for the material being processed and the kiln's specific design.

Why Kiln Temperatures Vary So Widely

Understanding the purpose of the kiln is the key to understanding its temperature. The heat is a tool used to force a specific change in a material, and different changes require different levels of heat.

The Material Dictates the Temperature

The core reason for a kiln's existence is to transform material. This could be drying, calcination, sintering, or inducing a chemical reaction.

Each of these processes has a precise thermal requirement. For example, sintering—the process of forming a solid mass of material by heat without melting it—requires a specific high temperature, such as 1288°C, to be effective.

The Kiln Type Determines the Capability

Different kiln designs are built to achieve different temperature ranges and heating methods.

A rotary kiln is a versatile workhorse, capable of supporting an extremely wide range of processes from 200°C to 2500°C. This adaptability makes it suitable for many different industries and materials.

Direct vs. Indirect Heating

The way heat is applied also influences the operational temperature. In an indirect rotary kiln, the furnace tube itself may reach 1200-1300°C.

However, the material inside the tube, which is heated through the tube wall, will be at a slightly lower temperature, often less than 1150°C. This distinction is critical for precise process control.

Understanding the Trade-offs

Choosing and operating a kiln at a specific temperature involves significant technical and economic trade-offs. It is not simply a matter of turning up the heat.

Energy Consumption

The energy required to achieve and maintain a kiln's temperature is a primary operational cost. Higher temperatures demand exponentially more fuel or electricity, directly impacting the economic viability of a process.

Material Integrity

Precision is paramount. If the temperature is too low, the desired chemical or physical transformation will not occur. If it is too high, the material can be damaged, melted, or fundamentally altered in undesirable ways.

Equipment Stress and Lifespan

Operating at the upper end of a kiln's temperature range, especially approaching 2500°C, places immense thermal and mechanical stress on the kiln's refractory lining and structural components. This can shorten the equipment's lifespan and increase maintenance costs.

Matching the Kiln to the Process

To determine the right temperature, you must first define your goal. Different objectives require entirely different thermal approaches.

- If your primary focus is a specific transformation like sintering: You need a kiln engineered for a precise, high-temperature window, often in the 1200°C to 1300°C range.

- If your primary focus is process versatility for multiple materials: A rotary kiln offers the broadest operational spectrum, from low-temperature drying to high-temperature synthesis.

- If your primary focus is controlled, gentle heating: An indirect kiln allows for precise material temperature management that is separate from the furnace's peak heat.

Ultimately, the right kiln temperature is the one that achieves your desired material outcome safely, efficiently, and reliably.

Summary Table:

| Process Goal | Typical Kiln Type | Approximate Temperature Range |

|---|---|---|

| Low-Temp Drying | Rotary Kiln | 200°C - 400°C (392°F - 752°F) |

| Sintering | Sintering Kiln | ~1288°C (2350°F) |

| High-Temp Synthesis | Rotary Kiln | Up to 2500°C (4532°F) |

| Controlled Heating | Indirect Kiln | Material temp < 1150°C (2102°F) |

Unlock the Perfect Thermal Process for Your Materials

Choosing the right kiln and operating temperature is critical for your project's success, impacting everything from product quality to energy costs. The wrong temperature can lead to incomplete reactions, damaged materials, or wasted resources.

At KINTEK, we specialize in providing precision lab equipment and consumables tailored to your specific thermal processing needs. Whether you require a versatile rotary kiln for multiple applications or a specialized sintering furnace for exact temperature control, our experts can help you select the ideal solution.

Let KINTEK be your partner in precision heating. We'll help you navigate the trade-offs between temperature, energy use, and equipment longevity to ensure your process is both efficient and effective.

Contact our thermal processing experts today for a personalized consultation and discover the KINTEK difference in laboratory excellence.

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How do furnaces contribute to sodium battery cathode performance? Mastering Solid-State Synthesis for Energy Storage

- What temperature should annealing steel be? Master the Critical Range for Perfect Results

- What is vacuum evaporation method? A Guide to Thin-Film Deposition & Purification

- What is a sintering process? A Guide to Fusing Powders into High-Performance Parts

- What is the significance of using high-vacuum heat treatment furnaces and rapid quenching for zirconium alloys?

- What furnace is needed for Al2O3/Cu-Cr softening resistance? Precision Thermal Stability Testing Guide

- What is the VAR melting process? The Ultimate Guide to Vacuum Arc Remelting

- What material is used for melting furnace? It's a System of Specialized Components