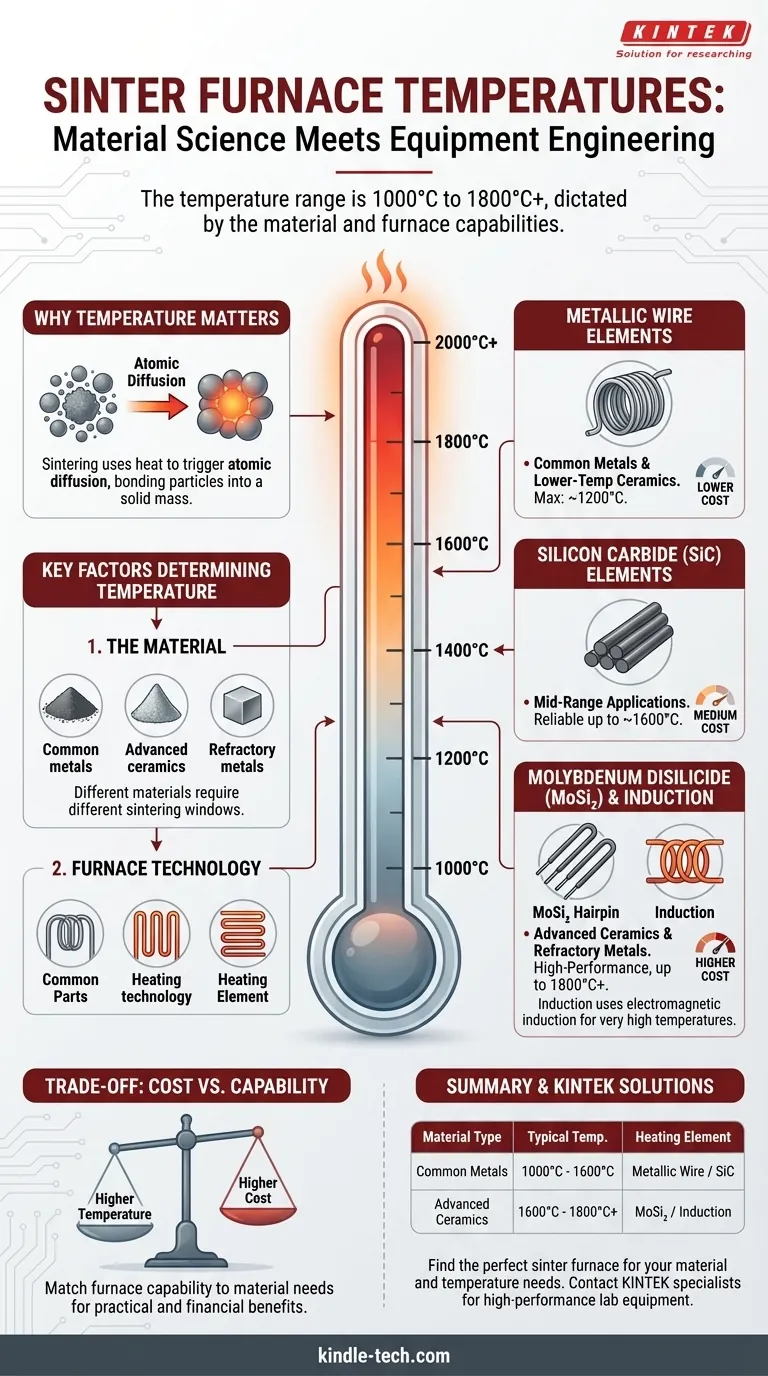

In short, a sinter furnace operates at temperatures typically ranging from 1000°C to over 1800°C (1832°F to 3272°F). The precise temperature is not a single value but is dictated by two primary factors: the specific material being processed and the technological limits of the furnace's heating elements.

The core principle to understand is that the required sintering temperature is a property of the material you are working with. The furnace you use must have heating technology capable of reaching and sustaining that specific temperature, creating a direct link between material science and equipment engineering.

Why Temperature is the Central Variable in Sintering

Sintering is a thermal process that densifies a powder compact, bonding particles together to create a solid, coherent mass. This is achieved by heating the material to a temperature below its melting point.

The Role of Atomic Diffusion

The high temperature provides the energy needed to trigger atomic diffusion. Atoms migrate across the boundaries of the particles, causing the individual grains to fuse and the voids between them to shrink.

Without sufficient temperature, this diffusion process will not occur, and the material will remain a loose powder. If the temperature is too high, the material will melt, losing its shape and structure.

Key Factors Determining Furnace Temperature

The operational temperature of a sinter furnace is not arbitrary. It is a function of the material's requirements and the furnace's design capabilities.

The Material Being Sintered

This is the most critical factor. Different materials have vastly different sintering windows. For example, some metal powders can be sintered at lower temperatures, while advanced ceramics and refractory metals require extremely high heat to initiate atomic diffusion.

The Technology of the Heating Elements

The maximum achievable temperature of a furnace is fundamentally limited by the materials used for its heating elements. This is the most common point of differentiation in standard chamber furnaces.

- Metallic Wire Elements: These are common in lower-temperature applications, typically achieving maximum temperatures between 1000°C and 1200°C.

- Silicon Carbide (SiC) Elements: For mid-range temperatures, SiC elements are used. These can reliably reach up to 1600°C.

- Molybdenum Disilicide (MoSi2) Elements: These are the standard for high-temperature laboratory and production furnaces, capable of achieving up to 1800°C.

The Furnace Design

Beyond heating elements, the overall furnace design plays a role. An induction furnace, for instance, does not use traditional resistance heating elements. Instead, it uses electromagnetic induction to heat the material directly.

Depending on the efficiency of the inductive coupling, these specialized furnaces can reach temperatures of 1800°C or significantly more, making them suitable for the most demanding applications.

Understanding the Trade-offs: Cost vs. Capability

Choosing or specifying a sinter furnace involves a direct trade-off between its temperature capability and its cost.

Higher Temperature Equals Higher Cost

Furnaces equipped with high-performance heating elements like Molybdenum Disilicide are significantly more expensive than those with standard metallic wire elements. This cost is reflected in both the initial equipment purchase and the long-term operational expenses, including energy consumption and element replacement.

Balancing Needs with Budget

The goal is to match the furnace's capability to the material portfolio. There is no practical or financial benefit to acquiring an 1800°C furnace if the materials you work with only require sintering at 1100°C. A thorough understanding of your material requirements is essential to making a sound investment.

Making the Right Choice for Your Goal

To select the appropriate furnace, you must first define the temperature requirements of your materials.

- If your primary focus is on common metals or lower-temperature ceramics: A chamber furnace with metallic wire or silicon carbide elements (1000°C - 1600°C) is the most practical and cost-effective solution.

- If your primary focus is on advanced ceramics, refractory metals, or cutting-edge material research: You will require a high-performance furnace with Molybdenum Disilicide elements or a specialized induction furnace capable of reaching 1800°C and beyond.

Ultimately, understanding the relationship between your material's properties and the furnace's heating technology is the key to successful and efficient sintering.

Summary Table:

| Material Type | Typical Sintering Temperature Range | Common Heating Element |

|---|---|---|

| Common Metals / Lower-Temp Ceramics | 1000°C - 1600°C | Metallic Wire / Silicon Carbide (SiC) |

| Advanced Ceramics / Refractory Metals | 1600°C - 1800°C+ | Molybdenum Disilicide (MoSi₂) / Induction |

Ready to find the perfect sinter furnace for your specific material and temperature needs?

At KINTEK, we specialize in providing high-performance lab equipment, including a full range of sinter furnaces tailored for everything from common metals to advanced ceramics. Our experts will help you select the right furnace with the precise temperature capability you require, ensuring optimal results and efficiency for your laboratory.

Contact our specialists today for a personalized consultation and discover the KINTEK difference in sintering solutions!

Visual Guide

Related Products

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Spark Plasma Sintering Furnace SPS Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

People Also Ask

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- How does a high-temperature vacuum sintering furnace facilitate the post-treatment of Zirconia coatings?

- Why is a high vacuum required for sintering Ti-43Al-4Nb-1Mo-0.1B? Ensure Purity & Fracture Toughness

- What is sintering reaction? Transform Powders into Dense Solids Without Melting

- Does sintering use diffusion? The Atomic Mechanism for Building Stronger Materials