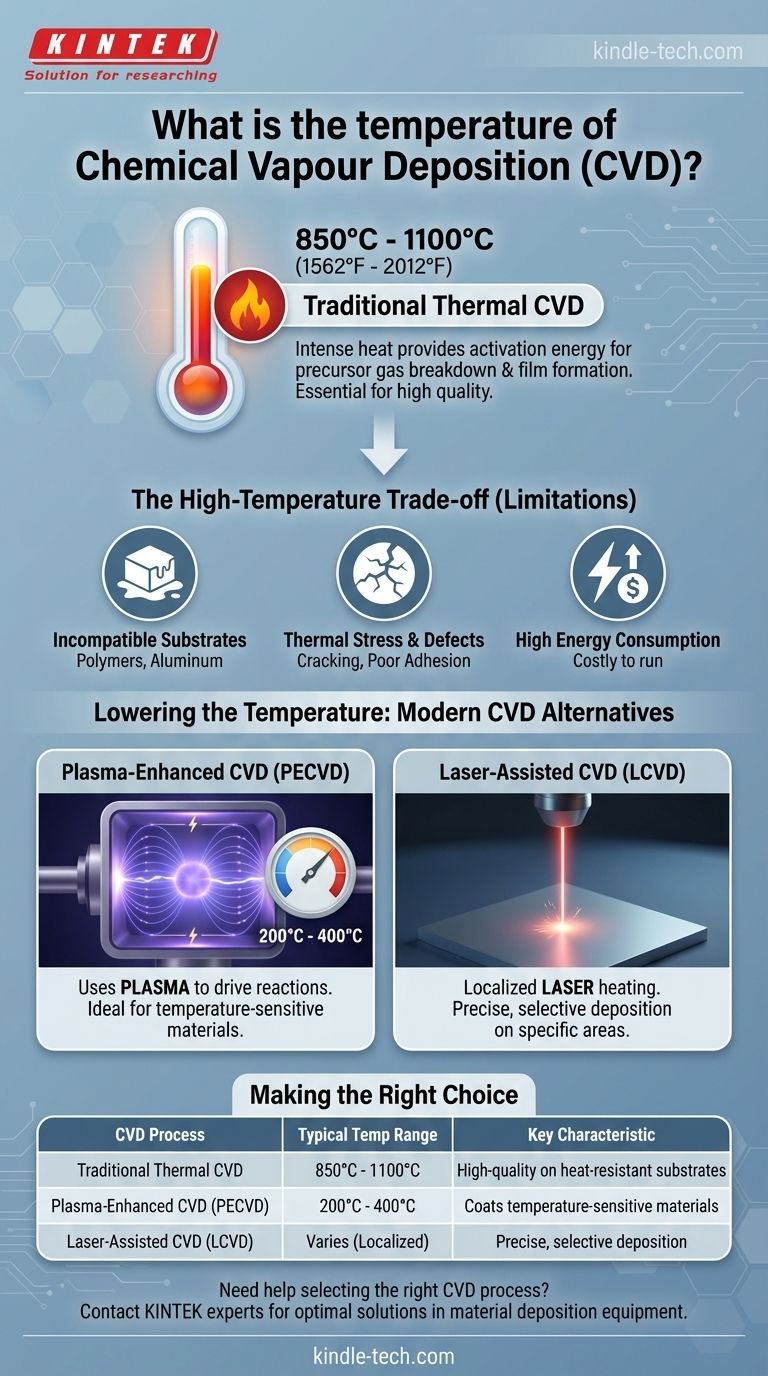

In short, traditional Chemical Vapor Deposition (CVD) is a high-temperature process, typically operating in a range of 850°C to 1100°C (1562°F to 2012°F). This intense heat is necessary to provide the activation energy required to break down the precursor gases and drive the chemical reactions that form a solid film on a substrate.

The core issue is not just the temperature itself, but the trade-off it creates. While extreme heat is essential for conventional CVD's high-quality film growth, it severely limits the types of materials that can be coated. Modern variations of CVD solve this problem by using alternative energy sources, like plasma, to enable deposition at much lower temperatures.

Why CVD Requires Such High Temperatures

The high operating temperature is fundamental to the "chemical" aspect of Chemical Vapor Deposition. The thermal energy serves as the primary catalyst for the entire process.

The Role of Thermal Energy

Heat provides the activation energy needed for the chemical reactions to occur. In CVD, precursor gases are introduced into a reaction chamber, and the high temperature causes them to decompose into reactive species.

Driving Surface Reactions

Once the gases have decomposed, the heat facilitates their reaction on the surface of the substrate. This controlled reaction is what builds the thin film layer by layer, ensuring a dense and pure coating.

Controlling Film Quality

Temperature is one of the most critical parameters for controlling the final properties of the deposited film. By precisely adjusting the temperature, operators can influence the material's crystallinity, grain size, purity, and internal stress, as mentioned in the process characteristics.

Understanding the Trade-offs: The High-Temperature Limitation

The primary drawback of conventional thermal CVD is its reliance on extreme heat, which creates significant challenges.

Substrate Incompatibility

The most significant limitation is that many substrate materials simply cannot withstand temperatures of 850°C or higher. Materials like polymers, many common metals (e.g., aluminum), and certain electronic components would melt, warp, or be destroyed.

Thermal Stress and Defects

Even if a substrate can survive the heat, the difference in thermal expansion between the substrate and the coating can create immense internal stress upon cooling. This can lead to cracking, poor adhesion, or delamination of the deposited film.

Energy Consumption

Maintaining a furnace at ~1000°C requires a substantial amount of energy, making it a costly process to run, especially at an industrial scale.

Lowering the Temperature: Modern CVD Alternatives

To overcome the high-temperature limitation, several alternative CVD techniques have been developed. These methods replace or supplement thermal energy with other forms of energy to drive the chemical reactions.

Plasma-Enhanced CVD (PECVD)

This is the most common low-temperature alternative. Instead of relying solely on heat, PECVD uses an electric field to generate a plasma (an ionized gas). The energetic electrons and ions in the plasma provide the energy to break down the precursor gases, allowing deposition to occur at much lower temperatures, often in the 200°C to 400°C range.

Laser-Assisted CVD (LCVD)

In this technique, a focused laser beam provides intense, localized heating directly on the substrate where the film is desired. This allows the chemical reaction to occur without heating the entire substrate, protecting temperature-sensitive components.

Making the Right Choice for Your Goal

Selecting the correct deposition method depends entirely on the substrate material and the desired film properties.

- If your primary focus is the highest possible purity and crystallinity on a heat-resistant substrate (like silicon or ceramics): Traditional, high-temperature thermal CVD is often the superior choice.

- If your primary focus is coating a temperature-sensitive substrate (like plastic, glass, or aluminum): A low-temperature method like Plasma-Enhanced CVD (PECVD) is the necessary approach.

- If your primary focus is precise, selective deposition on a small, specific area: Laser-Assisted CVD (LCVD) provides a unique solution by heating only the target region.

Understanding the role of temperature is the key to selecting the specific CVD process that aligns with your material and performance requirements.

Summary Table:

| CVD Process Type | Typical Temperature Range | Key Characteristic |

|---|---|---|

| Traditional Thermal CVD | 850°C - 1100°C (1562°F - 2012°F) | High-quality films on heat-resistant substrates |

| Plasma-Enhanced CVD (PECVD) | 200°C - 400°C | Enables coating of temperature-sensitive materials |

| Laser-Assisted CVD (LCVD) | Varies (localized heating) | Precise, selective deposition on small areas |

Need help selecting the right CVD process for your specific substrate and film requirements?

At KINTEK, we specialize in providing laboratory equipment and consumables for advanced material deposition processes. Whether you're working with high-temperature resistant materials or temperature-sensitive substrates like polymers and electronics, our experts can help you choose the optimal solution for your research or production needs.

Contact us today to discuss how our CVD solutions can enhance your material coating applications and achieve your performance goals.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition