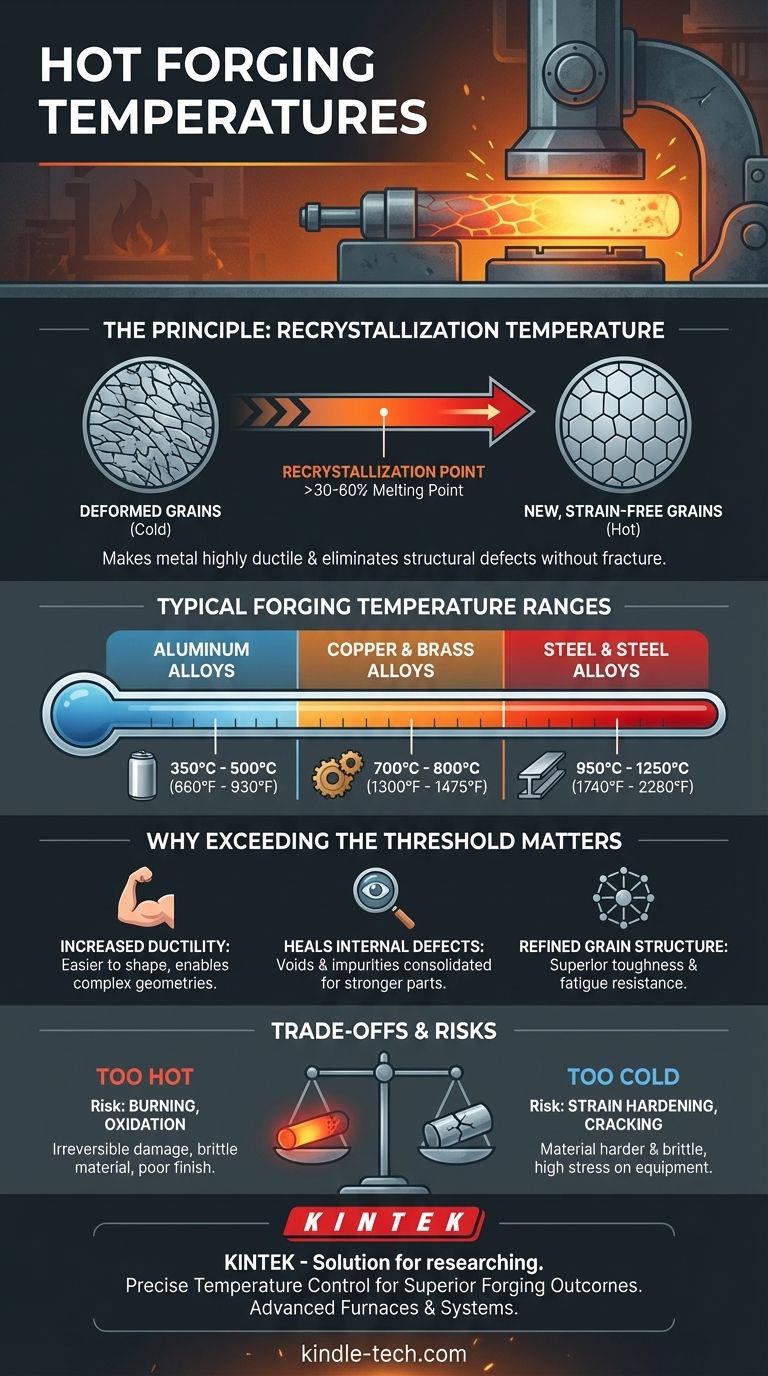

In short, the temperature for hot forging is set above a metal's recrystallization point, which is the threshold where its internal grain structure can reform under pressure. For common metals, this typically means temperatures ranging from 350°C (660°F) for aluminum alloys up to 1250°C (2280°F) for high-alloy steels. The exact temperature is critical and is chosen based on the specific alloy being worked.

The core principle of hot forging is not about reaching an arbitrary high temperature, but about surpassing a specific metallurgical threshold—the recrystallization temperature—to make the metal highly ductile and eliminate structural defects without causing it to fracture.

The Principle Behind Hot Forging Temperatures

To understand hot forging, you must first understand the concept that governs it. The process is defined by temperature, but the goal is to control the metal's internal crystal structure.

What is Recrystallization?

Recrystallization is a process where deformed grains in a metal's crystal structure are replaced by new, strain-free grains. Imagine a box of sugar cubes (the grains) that gets crushed. Recrystallization is like magically replacing all the broken cubes with perfect new ones.

Heating a metal above its recrystallization temperature energizes its atoms, allowing them to rearrange into this new, ideal structure even as the material is being shaped. This temperature is typically between 30% and 60% of the metal's absolute melting point.

Why Exceeding This Temperature Matters

Working a metal above its recrystallization point fundamentally changes its behavior and provides several key advantages.

First, it dramatically increases ductility and reduces the yield strength, making the metal soft and easy to shape. This allows for the creation of complex geometries that would be impossible with cold forming.

Second, the immense force of the forging press combined with the high temperature heals internal defects. Voids, porosity, and impurities from the initial casting process are consolidated and welded shut, resulting in a much stronger and more reliable final part.

Finally, the process refines the grain structure, creating a fine, uniform grain pattern. This refined structure is a primary reason why forged components possess superior toughness and fatigue resistance compared to cast or machined parts.

Forging Temperatures for Common Metals

While the principle of recrystallization is universal, the exact temperature window is unique to each alloy family. Precise temperature control is essential for a successful outcome.

Steel and Steel Alloys

Steel is the most commonly forged material. The forging temperature for steel generally falls between 950°C and 1250°C (1740°F to 2280°F). Carbon steels are worked at the higher end of this range, while some alloy steels require more precise, lower-temperature controls.

Aluminum Alloys

Aluminum has a much lower melting point and, therefore, a lower forging temperature. Forging for aluminum alloys is typically conducted between 350°C and 500°C (660°F to 930°F). This range is narrow, and exceeding it can easily damage the material.

Copper and Brass Alloys

Copper-based alloys, including brass and bronze, are forged at temperatures that fall between those of aluminum and steel. The typical range is between 700°C and 800°C (1300°F to 1475°F).

Understanding the Trade-offs and Risks

Choosing the right temperature is a balancing act. Deviating from the optimal window introduces significant risks that can compromise the integrity of the final product.

The Danger of Overheating

If the forging temperature is too high, it can lead to burning, where the grain boundaries of the metal begin to melt. This damage is irreversible and severely degrades the material's mechanical properties, making the part brittle and useless.

Excessive heat also promotes rapid oxidation, which forms a thick layer of scale on the part's surface. This scale can be pressed into the surface during forging, leading to a poor finish and dimensional inaccuracies.

The Problem of Forging Too Cold

Attempting to forge below the proper recrystallization temperature prevents the grain structure from fully reforming. This leads to a phenomenon called strain hardening, where the material becomes harder and more brittle as it is worked.

Forging too cold requires significantly more force, puts extreme stress on the equipment, and increases the risk of surface cracking or even complete fracture of the workpiece.

Making the Right Choice for Your Goal

The decision to use hot forging and the specific temperature selected should be driven by the intended application of the final component.

- If your primary focus is creating complex shapes with maximum formability: Hot forging is the ideal choice, as working above the recrystallization temperature provides extreme ductility for intricate designs.

- If your primary focus is achieving a precise surface finish and tight tolerances: Consider warm or cold forging, which avoid the surface scaling of hot forging and can achieve near-net shapes with less machining.

- If your primary focus is producing a tough, fatigue-resistant component: Hot forging is often superior for its ability to heal internal defects and refine the grain structure, creating a more durable final product.

Ultimately, precise temperature control is the key to unlocking the exceptional strength and reliability that makes forging a premier manufacturing process.

Summary Table:

| Metal/Alloy | Typical Hot Forging Temperature Range |

|---|---|

| Steel & Steel Alloys | 950°C - 1250°C (1740°F - 2280°F) |

| Aluminum Alloys | 350°C - 500°C (660°F - 930°F) |

| Copper & Brass Alloys | 700°C - 800°C (1300°F - 1475°F) |

Ready to achieve precise temperature control for your hot forging process?

KINTEK specializes in high-performance lab equipment and consumables, serving the precise thermal processing needs of metallurgical labs and manufacturing facilities. Our advanced furnaces and temperature control systems help you maintain the exact recrystallization temperatures required for superior metal forming, ensuring your components achieve maximum strength, ductility, and defect-free integrity.

Contact us today to discuss how our solutions can enhance your forging outcomes and bring reliability to your production line.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Laboratory High Pressure Vacuum Tube Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- Why are precise temperature and pressure controls in a Laboratory Hot Press essential for PBAT composites?

- What is the function of a hydraulic hot press in TlBr crystal preparation? Master High-Density Semiconductor Growth

- What is hot press lamination? The Ultimate Guide to Strong, Durable Material Bonding

- Why is a laboratory hot press essential for PTFE and nickel foam Zinc-Air electrodes? Precision Microstructure Control

- What is the process of hot press forging? Create High-Strength Metal Components with Precision

- What is a hydraulic hot press? A Guide to Precision Heat and Pressure for Manufacturing

- Why is precise temperature control within the supercooled liquid region necessary when using a hot press? (Full Guide)

- What is the temperature range for compression molding? Optimize Your Process for Perfect Parts