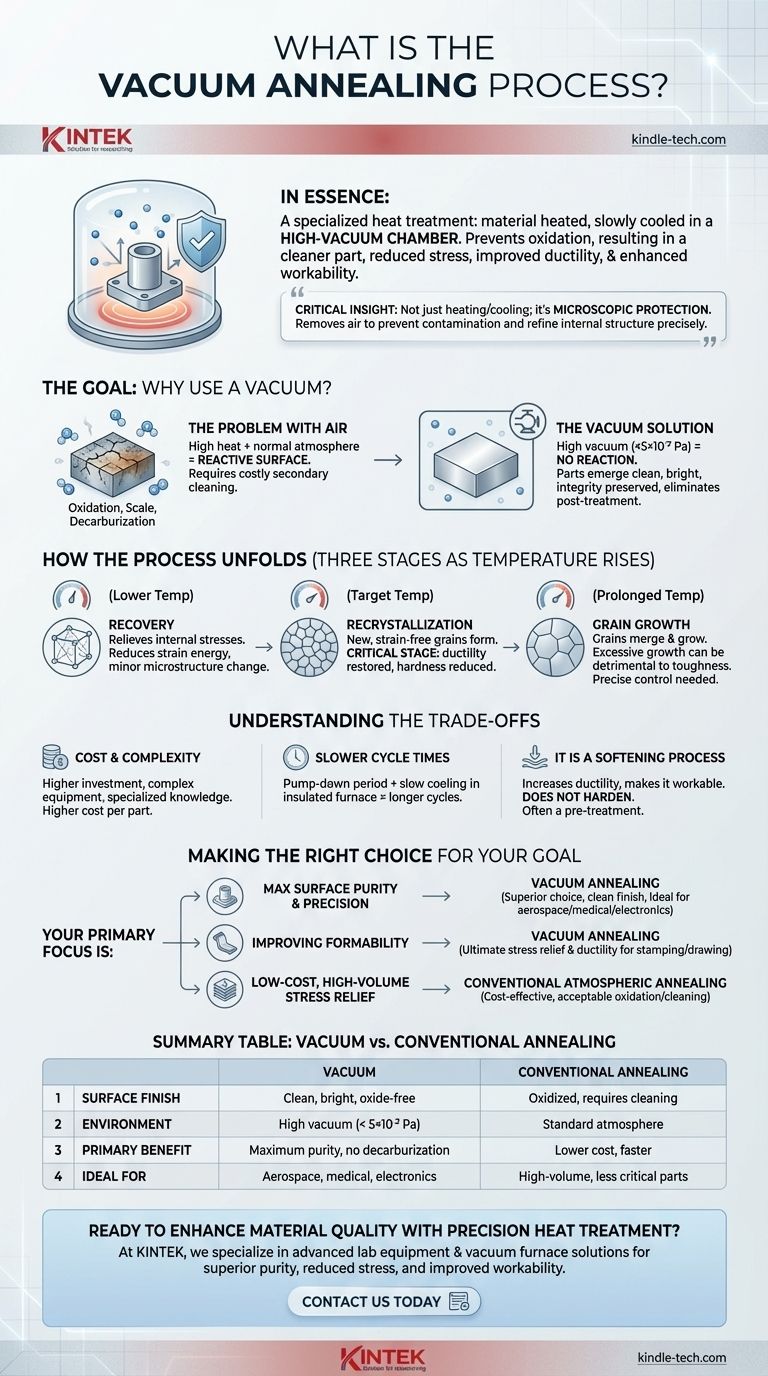

In essence, vacuum annealing is a specialized heat treatment process where a material, typically a metal, is heated to a specific temperature and then slowly cooled inside a high-vacuum chamber. This controlled environment prevents surface reactions like oxidation, resulting in a cleaner part with reduced internal stress, improved ductility, and enhanced workability.

The critical insight is that performing the annealing process in a vacuum is not just about heating and cooling; it's about fundamentally protecting the material at a microscopic level. By removing air, you prevent surface contamination and ensure the metal's internal structure can be refined with maximum precision.

The Goal: Why Use a Vacuum?

The primary purpose of annealing is to reverse the effects of work hardening—the process where metal becomes harder and more brittle as it is bent, rolled, or machined. Vacuum annealing achieves this with superior results.

The Problem with Air

When metal is heated to high temperatures, its surface becomes highly reactive. In a normal atmosphere, oxygen and other gases react with the metal, creating an oxide layer (scale or discoloration) and potentially changing the chemistry of the surface layer, a process known as decarburization in steels.

This surface contamination can be detrimental for high-precision components, requiring costly and difficult secondary cleaning operations like grinding or chemical pickling.

The Vacuum Solution

By performing the annealing process in a high vacuum (often below 5×10⁻² Pascals), there are virtually no gas molecules left to react with the hot metal surface.

This results in a part that emerges from the furnace clean, bright, and free from surface oxidation. It preserves the material's integrity and often eliminates the need for post-treatment finishing.

How the Annealing Process Unfolds

Regardless of the environment, annealing transforms the metal's internal crystal structure in three distinct stages as the temperature rises.

Stage 1: Recovery

At lower temperatures, the process begins to relieve internal stresses within the metal's crystal lattice. This stage reduces some of the strain energy stored during work hardening without significantly changing the microstructure.

Stage 2: Recrystallization

As the temperature increases to the target point, new, strain-free crystals (or grains) begin to form and replace the deformed ones created during work hardening. This is the critical stage where the material's ductility is restored and its hardness is significantly reduced.

Stage 3: Grain Growth

If the material is held at the annealing temperature for too long, the newly formed, strain-free grains will begin to merge and grow larger. While this can further increase ductility, excessive grain growth can sometimes be detrimental to other properties like toughness, which is why temperature and time are so precisely controlled in a vacuum furnace.

Understanding the Trade-offs

Vacuum annealing is a powerful technique, but it is not the universal solution for all applications. Understanding its limitations is key to using it effectively.

Cost and Complexity

Vacuum furnaces are complex, expensive machines that require significant capital investment and specialized knowledge to operate and maintain. The cost per part is therefore higher than for conventional atmospheric furnace annealing.

Slower Cycle Times

Achieving a high vacuum requires a "pump-down" period before heating can begin. Furthermore, cooling is often done slowly inside the insulated furnace to ensure maximum stress relief. These factors can lead to longer overall cycle times compared to other heat treatments.

It Is a Softening Process

It is crucial to remember that annealing softens metal to make it more ductile and workable. It does not make it harder. Applications like knife blades use vacuum annealing to create a perfect, stress-free internal structure before a separate hardening and tempering process is used to achieve the final desired sharpness and toughness.

Making the Right Choice for Your Goal

Selecting the right heat treatment depends entirely on your final objective for the material.

- If your primary focus is maximum surface purity and precision: Vacuum annealing is the superior choice, as it prevents oxidation and delivers a clean, bright finish ideal for medical, aerospace, or electronic components.

- If your primary focus is improving formability for subsequent manufacturing: Vacuum annealing provides the ultimate stress relief and ductility, making the material exceptionally easy to stamp, draw, or machine.

- If your primary focus is low-cost, high-volume stress relief: Conventional atmospheric annealing may be more cost-effective, provided that some surface oxidation and the need for subsequent cleaning are acceptable.

Ultimately, choosing vacuum annealing is an investment in material quality and process reliability.

Summary Table:

| Aspect | Vacuum Annealing | Conventional Annealing |

|---|---|---|

| Surface Finish | Clean, bright, oxide-free | Oxidized, requires cleaning |

| Environment | High vacuum (< 5×10⁻² Pa) | Standard atmosphere |

| Primary Benefit | Maximum purity, no decarburization | Lower cost, faster for some applications |

| Ideal For | Aerospace, medical, electronics | High-volume, less critical parts |

Ready to enhance your material quality with precision heat treatment?

At KINTEK, we specialize in advanced lab equipment, including vacuum furnace solutions, to meet the demanding needs of laboratories and manufacturing facilities. Our expertise ensures you achieve the superior surface purity, reduced internal stress, and improved workability required for high-performance components.

Contact us today to discuss how our vacuum annealing solutions can optimize your process and deliver reliable, contamination-free results. Get in touch via our contact form – let's achieve your material goals together.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the heat treatment process furnace? The Precision Tool for Material Transformation

- What is the temperature of vacuum casting? Mastering the Thermal Profile for Flawless Parts

- What is arc melting process? A Guide to High-Temperature Metal Melting for Steel Production

- What function does a vacuum drying oven serve in HSE and NaFePO4 production? Enhance Battery Stability and Purity

- Why Use Ultra-High Vacuum Furnaces for LLZO? Ensure Chemical Stability & Interface Integrity in Solid Electrolytes

- What are the applications of resistance furnace? Precision Heating for Metal Treatment & More

- What types of steel can be quenched? A Guide to Hardenable Steels for Optimal Performance

- What are the advantages of brazing? Achieve Superior Joint Integrity for Complex Assemblies