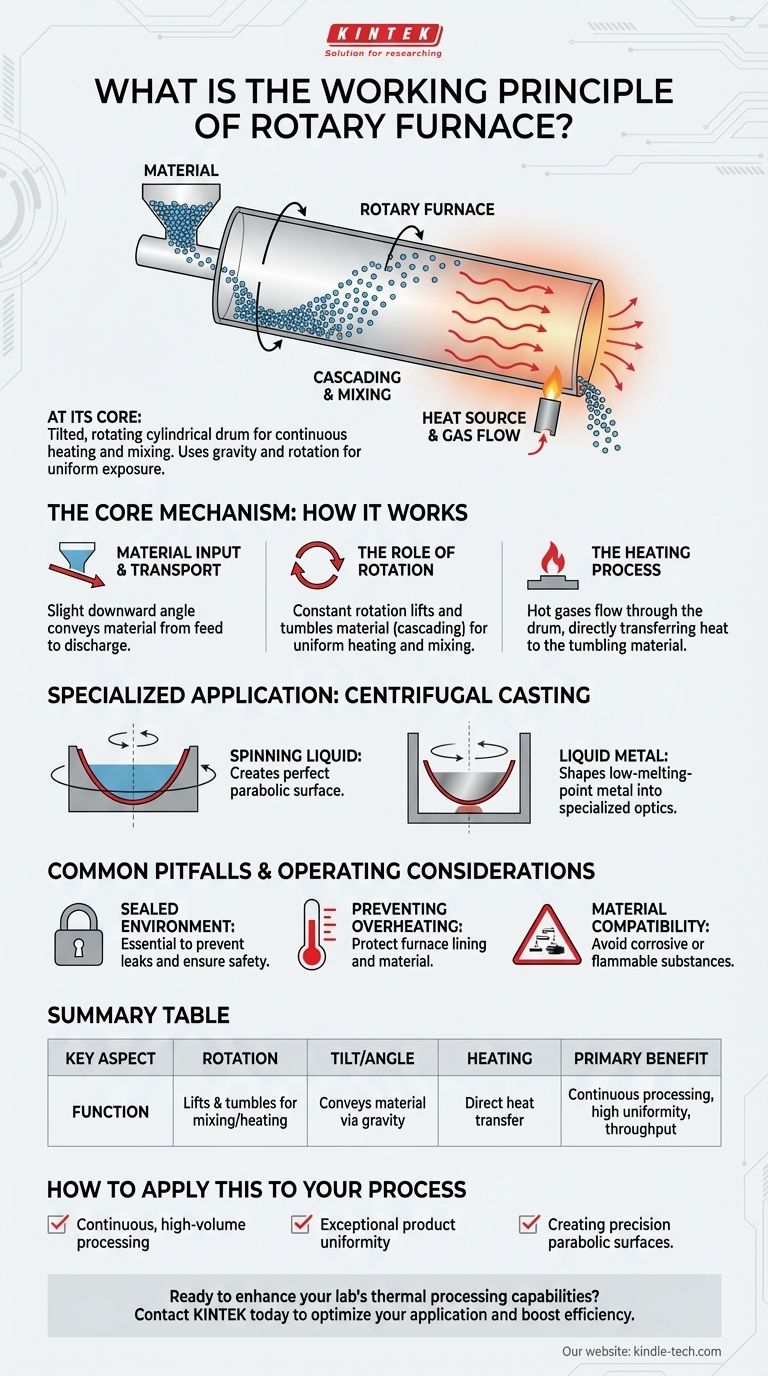

At its core, a rotary furnace is a slightly tilted, rotating cylindrical drum designed to continuously heat and mix materials. As the furnace rotates, the material tumbles and is gradually transported from the higher entry point to the lower exit point, ensuring uniform exposure to the internal heat source.

The fundamental principle of a rotary furnace is its use of mechanical rotation and a slight gravitational incline to simultaneously mix, heat, and convey materials, making it ideal for continuous thermal processing that requires high uniformity.

The Core Mechanism: How It Works

A rotary furnace integrates three key actions—transport, mixing, and heating—into a single, continuous process. Understanding how these actions synchronize is key to grasping its function.

### Material Input and Transport

Material, either as a dry blend or a wet pulp, is introduced at the elevated end of the furnace.

The furnace is angled slightly downward. This gentle slope, combined with the rotation, ensures the material slowly but consistently moves from the feed end to the discharge end.

### The Role of Rotation

The constant rotation of the drum is the most critical aspect of the design.

This rotation continuously lifts and tumbles the material. This action, known as "cascading," ensures that new surfaces are constantly exposed to the heat source.

This tumbling also serves as a highly effective mixing mechanism, guaranteeing a homogenous final product.

### The Heating Process

A heat source, often a burner using gas, oil, or pulverized solid fuel, is typically positioned at one end of the furnace.

The hot gases produced by the burner flow through the length of the rotating drum, directly transferring heat to the tumbling material. This direct contact is an efficient method of heat transfer.

A Specialized Application: Centrifugal Casting

While most rotary furnaces are used for heat treatment and processing, a unique application leverages the physics of rotation for manufacturing.

### Creating Parabolic Surfaces

When a liquid is spun on a horizontal axis, centrifugal force naturally pushes it into a perfect paraboloid shape.

This principle is used in rotary furnaces to create specialized optics, like mirrors for telescopes.

### The Process with Liquid Metals

In this application, a low-melting-point metal like gallium or mercury is placed inside the furnace.

The furnace is heated to melt the metal and then spun at a precise speed. The centrifugal force shapes the liquid metal into a concave parabolic surface. The rotation continues until the metal cools and solidifies, permanently locking in the shape.

Common Pitfalls and Operating Considerations

To ensure safe and effective operation, several factors must be managed carefully. The design's strengths can become liabilities if not properly controlled.

### Maintaining a Sealed Environment

The furnace must be properly sealed before operation. Any leaks can disrupt the internal atmosphere, compromise the process, and create a safety hazard.

### Preventing Overheating

Overheating can damage both the furnace lining and the material being processed. Temperature is carefully controlled by managing the fuel rate and, in some industrial processes, by adding cooling agents as needed.

### Material Compatibility

It is critical to avoid processing materials that are highly corrosive or could produce flammable gases when heated. These substances can damage the furnace and create an unsafe working environment.

How to Apply This to Your Process

The decision to use a rotary furnace depends entirely on the specific requirements of your thermal processing task.

- If your primary focus is continuous, high-volume processing: The constant flow-through design makes the rotary furnace ideal for industrial applications where throughput is critical.

- If your primary focus is exceptional product uniformity: The constant tumbling and mixing action is superior to static furnaces for achieving a homogenous end product.

- If your primary focus is creating precision parabolic surfaces: The specialized application of centrifugal casting in a rotary furnace is a unique and effective manufacturing method for optics.

Ultimately, the rotary furnace is an elegant engineering solution for processes that demand both continuous motion and uniform heating.

Summary Table:

| Key Aspect | Function |

|---|---|

| Rotation | Lifts and tumbles material for uniform mixing and heating (cascading). |

| Tilt/Angle | Uses gravity to convey material from feed end to discharge end. |

| Heating | Direct contact with hot gases ensures efficient heat transfer. |

| Primary Benefit | Continuous processing with high product uniformity and throughput. |

Ready to enhance your lab's thermal processing capabilities?

A rotary furnace from KINTEK can revolutionize your continuous heat treatment, calcination, or drying processes. Our expertise in lab equipment ensures you get a solution tailored for exceptional product uniformity and high-volume throughput.

Contact KINTEK today to discuss how a rotary furnace can optimize your specific application and boost your lab's efficiency.

Visual Guide

Related Products

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- What is a rotary heat type furnace? The Ultimate Guide to Uniform Heating & Mixing

- At what temperature does wood pyrolysis begin? Control the Process for Biochar, Bio-Oil, or Syngas

- Why is a high-temperature furnace with multi-probe testing used for ABO3 perovskite? Get Precise Conductivity Data

- What are the process advantages of using a rotary tube furnace for WS2 powder? Achieve Superior Material Crystallinity

- What is the function of a high-temperature furnace during burnout? Master Aluminum Foam Production with Precision