At its core, thermal vapor deposition is a straightforward coating technique that works by heating a solid material inside a high-vacuum chamber until it evaporates. This vapor then travels and condenses onto a cooler surface, known as the substrate, forming a very thin and uniform film. The entire process is a physical change of state, much like water boiling into steam and then forming condensation on a cold window.

The critical distinction to understand is that thermal deposition is a physical process (evaporation and condensation), which sets it apart from more complex chemical processes that create films through reactions on a surface. This fundamental difference dictates the method's advantages, limitations, and ideal applications.

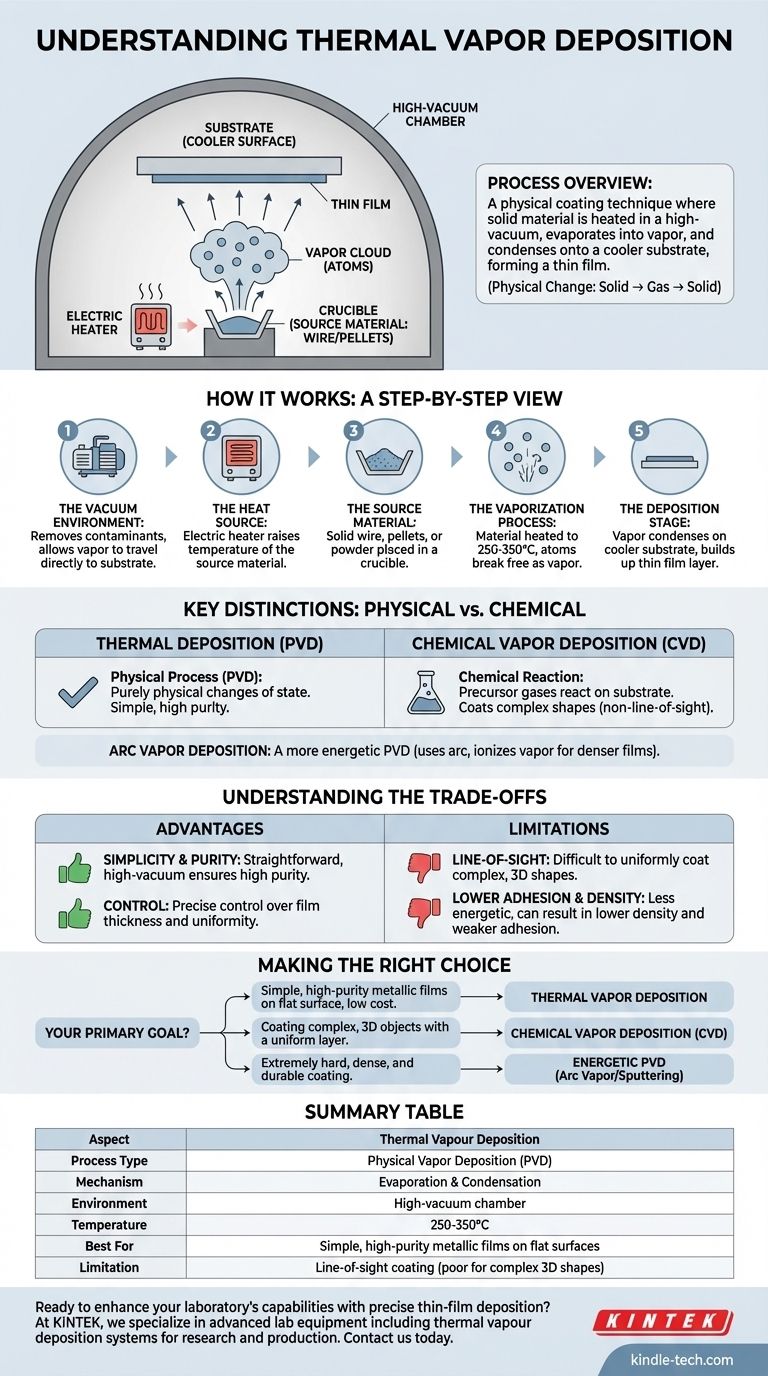

How Thermal Vapor Deposition Works: A Step-by-Step View

To truly grasp the technique, it's helpful to break it down into its essential stages. The process is elegant in its simplicity, relying on fundamental principles of physics.

The Vacuum Environment

The entire process must occur in a high-vacuum chamber. This serves two critical purposes: it removes air and other particles that could contaminate the final film, and it allows the vaporized atoms to travel directly to the substrate without colliding with anything else.

The Heat Source

An electric heater is used to raise the temperature of the source material. This is often done using small, heat-resistant containers called "boats" or crucibles, which hold the material to be vaporized.

The Source Material

The material intended to form the film is placed in the boat. It typically starts as a solid, often in the form of wire, pellets, or powder.

The Vaporization Process

The heater raises the temperature of the boat and the source material, typically between 250 to 350 degrees Celsius. As the material heats up, its atoms gain enough energy to break free from the solid state and turn directly into a gas, creating a vapor cloud.

The Deposition Stage

This vapor cloud expands throughout the vacuum chamber. When the vapor atoms come into contact with the cooler substrate, they lose their energy, condense back into a solid state, and build up layer by layer to form a thin film.

Key Distinctions: Physical vs. Chemical Deposition

The term "vapor deposition" covers a wide range of technologies. The most important distinction to make is between Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD). This is a frequent point of confusion.

Thermal Deposition is a PVD Process

Thermal vapor deposition is a classic example of Physical Vapor Deposition (PVD). The name says it all: the process involves purely physical changes of state (solid → gas → solid). No chemical reactions take place to form the film.

Chemical Vapor Deposition (CVD) is Fundamentally Different

In Chemical Vapor Deposition (CVD), precursor gases are introduced into a chamber. A chemical reaction is then triggered on the substrate's surface, causing a solid film to "grow." Unlike PVD, CVD can coat complex shapes more easily because the gas can flow around the object.

Arc Vapor Deposition: A More Energetic PVD

Another PVD method is arc vapor deposition. Instead of simple heat, it uses a high-current electric arc to vaporize the material. A key difference is that this process ionizes a large portion of the vapor atoms, making them more energetic, which can result in denser and more durable films.

Understanding the Trade-offs

Like any engineering process, thermal vapor deposition has a distinct set of advantages and limitations that make it suitable for some applications but not others.

Advantage: Simplicity and Purity

Because it relies on a simple heating and condensation mechanism, the equipment can be relatively straightforward and cost-effective. The high-vacuum environment ensures that the resulting film is of very high purity.

Advantage: Control

Engineers can precisely control the thickness and uniformity of the film by managing the temperature, deposition time, and distance between the source and the substrate.

Limitation: Line-of-Sight Deposition

The vapor travels in a straight line from the source to the substrate. This means it is very difficult to uniformly coat the back or undercut areas of a complex, three-dimensional object. This is a major contrast to CVD's excellent "wrap-around" capabilities.

Limitation: Lower Adhesion and Density

Compared to more energetic processes like arc deposition, the atoms in thermal deposition arrive at the substrate with relatively low energy. This can sometimes result in films with lower density and weaker adhesion to the substrate.

Making the Right Choice for Your Goal

Selecting the correct deposition technique requires understanding your ultimate goal for the thin film.

- If your primary focus is creating simple, high-purity metallic films on a flat surface at a low cost: Thermal vapor deposition is an excellent and highly effective choice.

- If your primary focus is coating complex, 3D objects with a uniform layer: Chemical Vapor Deposition (CVD) is the superior method due to its non-line-of-sight nature.

- If your primary focus is producing an extremely hard, dense, and durable coating: An energetic PVD process like arc vapor deposition or sputtering should be your primary consideration.

Understanding the fundamental mechanism behind each technique empowers you to select the right tool for the job.

Summary Table:

| Aspect | Thermal Vapour Deposition |

|---|---|

| Process Type | Physical Vapor Deposition (PVD) |

| Mechanism | Evaporation & Condensation |

| Environment | High-vacuum chamber |

| Temperature | 250-350°C |

| Best For | Simple, high-purity metallic films on flat surfaces |

| Limitation | Line-of-sight coating (poor for complex 3D shapes) |

Ready to enhance your laboratory's capabilities with precise thin-film deposition?

At KINTEK, we specialize in advanced lab equipment including thermal vapour deposition systems that deliver high-purity coatings for your research and production needs. Whether you're working with metallic films, semiconductors, or specialized coatings, our solutions offer the control and reliability your laboratory requires.

Contact us today to discuss how our deposition technology can advance your projects and bring superior results to your laboratory workflow.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- What are the components of PECVD? A Guide to Low-Temperature Thin Film Deposition Systems

- What are the advantages of plasma enhanced CVD? Enable Low-Temperature, High-Quality Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- What is plasma enhanced chemical vapor deposition PECVD equipment? A Guide to Low-Temperature Thin Film Deposition