In short, vacuum coating is used to apply an ultra-thin, high-performance layer of material onto a substrate to enhance its properties. This process is critical across numerous industries—from aerospace and automotive to electronics and medical—for improving durability, adding specific functions like electrical conductivity, or creating a superior decorative finish.

The core purpose of vacuum coating is not merely to cover a surface, but to fundamentally re-engineer it at a molecular level. By depositing materials atom by atom in a pristine vacuum, this technology grants a base material entirely new properties it could not otherwise possess.

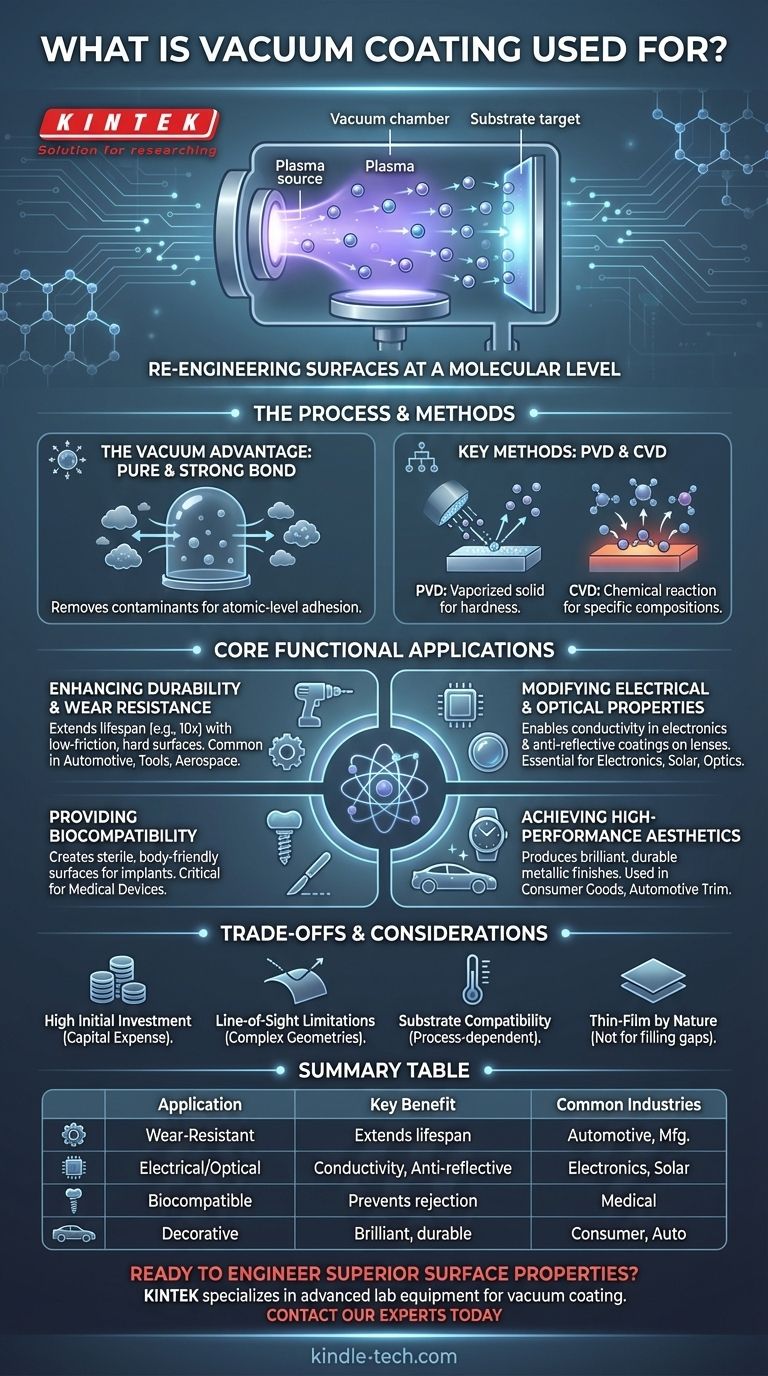

What is Vacuum Coating at a Fundamental Level?

Vacuum coating, or thin-film deposition, is a family of processes that take place inside a sealed, sub-atmospheric chamber. It is a method of adding function, not just a layer of paint.

A Process of Atomic Deposition

The goal is to deposit a very thin, perfectly uniform film of a specific material onto a target object, known as a substrate. This film can be anywhere from a few atoms thick to several microns (a human hair is about 70 microns thick).

The material being deposited travels through the vacuum and condenses onto the substrate, forming a dense, well-adhered coating.

The Critical Role of the Vacuum

Conducting this process in a vacuum is essential. It removes air and other atmospheric contaminants that would otherwise interfere with the coating process, react with the materials, and create an impure, weak, or non-uniform layer.

The vacuum ensures the deposited film is pure and bonds tightly to the substrate on an atomic level.

Key Methods: PVD and CVD

Two primary families of vacuum coating exist:

- Physical Vapor Deposition (PVD): In PVD, a solid source material is physically vaporized (e.g., through sputtering or evaporation) and then deposits onto the substrate. It is often used for hard, wear-resistant coatings.

- Chemical Vapor Deposition (CVD): In CVD, precursor gases are introduced into the chamber. They react on the hot surface of the substrate, leaving behind the desired solid film. This is crucial for creating specific material compositions, like those in semiconductors.

Core Functional Applications: Beyond Simple Protection

While protection is a benefit, the true power of vacuum coating lies in its ability to impart specific, engineered functions to a surface.

Enhancing Durability and Wear Resistance

This is one of the most common applications. Extremely hard materials like titanium nitride are deposited onto cutting tools, drill bits, engine components, and firearms.

This PVD coating dramatically extends the product's lifespan—sometimes by more than tenfold—by providing a low-friction, wear-resistant surface.

Modifying Electrical and Optical Properties

In electronics, vacuum deposition is used to create the microscopic metal patterns on microchips and the conductive layers in LEDs and thin-film solar cells.

For optics, it's used to apply anti-reflective coatings on eyeglass lenses and camera lenses, or low-emissivity (Low-E) films on architectural glass to save energy by reflecting thermal radiation.

Providing Biocompatibility and Chemical Barriers

Medical implants and surgical tools are often coated to make them biocompatible, ensuring the body does not reject them. The coating also provides a hard, sterile, and easy-to-clean surface.

In other industries, it can create a chemical barrier, such as on equipment used in food processing or dairy sheds.

Achieving High-Performance Aesthetics

Vacuum coating is a popular method for creating brilliant, durable metallic finishes on plastics, glass, and metal. It is widely used on automotive parts like wheels and trim as a more environmentally friendly and durable alternative to traditional chrome plating.

Understanding the Trade-offs and Considerations

While powerful, vacuum coating is a specific industrial process with its own set of constraints.

High Initial Investment

The equipment required—including the vacuum chamber, pumps, and power sources—represents a significant capital expense. This is not a workshop process but a sophisticated manufacturing technology.

Line-of-Sight Limitations

Many PVD processes are "line-of-sight," meaning they can only coat surfaces that are directly exposed to the vapor source. Coating complex internal geometries can be challenging and may require specialized fixtures or different techniques like CVD.

Substrate Compatibility

The chosen process must be compatible with the substrate material. For instance, some high-temperature CVD processes can melt or damage plastics and other low-temperature materials, making PVD a more suitable choice in those cases.

Thin-Film by Nature

These coatings are exceptionally thin. They are designed for enhancing surface properties, not for filling large gaps, hiding major surface defects, or providing heavy-duty impact resistance in the way a thick powder coat might.

Making the Right Choice for Your Goal

To apply this knowledge, match the technology to your primary objective.

- If your primary focus is extreme hardness and wear resistance: PVD coatings are the standard for tools, molds, and mechanical components.

- If your primary focus is creating conductive or semi-conductive layers: PVD and CVD are essential and non-negotiable for manufacturing electronics and solar cells.

- If your primary focus is a durable, decorative finish: PVD offers a high-end, environmentally cleaner alternative to traditional electroplating for automotive and consumer products.

- If your primary focus is modifying light transmission or reflection: Specialized optical PVD coatings are necessary for lenses, glass, and sensors.

Ultimately, vacuum coating allows you to engineer the surface of a material, fundamentally changing its performance to meet your precise technical requirements.

Summary Table:

| Application | Key Benefit | Common Industries |

|---|---|---|

| Wear-Resistant Coatings | Extends lifespan, reduces friction | Automotive, Manufacturing, Aerospace |

| Electrical/Optical Layers | Enables conductivity, anti-reflective properties | Electronics, Solar, Optics |

| Biocompatible Surfaces | Prevents rejection, ensures sterility | Medical Implants, Surgical Tools |

| Decorative Finishes | Provides durable, brilliant metallic looks | Consumer Goods, Automotive Trim |

Ready to engineer superior surface properties for your products? KINTEK specializes in advanced lab equipment and consumables for vacuum coating processes. Whether you're developing wear-resistant tools, medical devices, or high-performance electronics, our solutions ensure precise, reliable thin-film deposition. Contact our experts today to discuss how we can support your laboratory's innovation and production goals.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

People Also Ask

- What is plasma activated chemical vapor deposition? Enable Low-Temperature Thin Film Deposition

- How does plasma vapor deposition work? A Low-Temperature Coating Solution for Sensitive Materials

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What are the advantages of plasma enhanced CVD? Enable Low-Temperature, High-Quality Thin Film Deposition

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications