Manufacturing effective mullite pusher plates for hydrogen furnaces presents a significant challenge primarily due to the difficulty in establishing a strong, well-formed mullite bond during the production process. This inherent material challenge is compounded by the severe operating conditions within hydrogen furnaces, which render many standard ceramic formulations unsuitable.

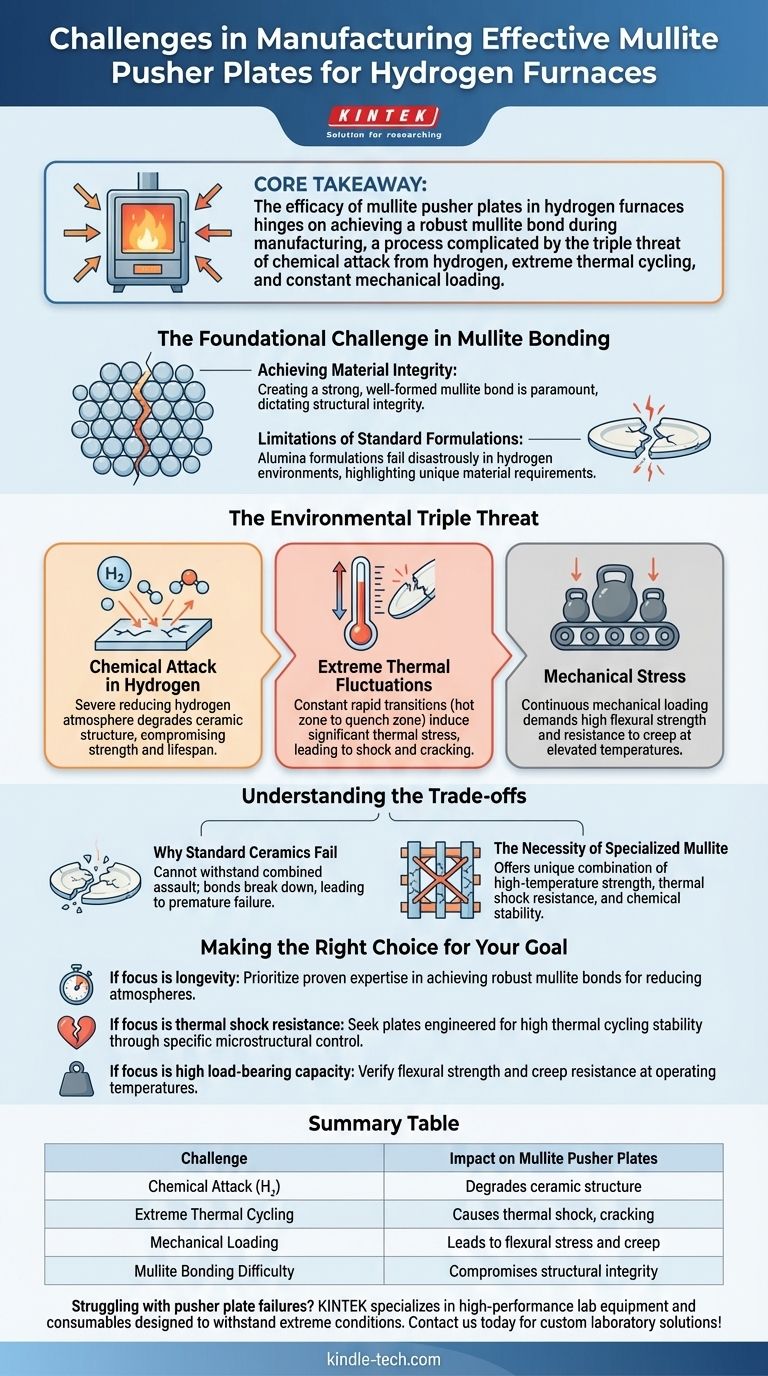

Core Takeaway: The efficacy of mullite pusher plates in hydrogen furnaces hinges on achieving a robust mullite bond during manufacturing, a process complicated by the triple threat of chemical attack from hydrogen, extreme thermal cycling, and constant mechanical loading.

The Foundational Challenge in Mullite Bonding

Achieving Material Integrity

Creating a strong, well-formed mullite bond is the paramount manufacturing hurdle. This bond dictates the plate's structural integrity and resistance to degradation.

Limitations of Standard Formulations

Alumina formulations, while effective in air-firing conditions even at high temperatures, often fail disastrously in the punishing hydrogen environments. This highlights the unique material requirements for hydrogen furnace applications.

The Environmental Triple Threat

The need for highly specialized ceramic pusher plates is driven by a unique combination of three extreme factors.

Chemical Attack in Hydrogen

The severe reducing hydrogen atmosphere inside these furnaces chemically attacks many materials. This environment can degrade the ceramic structure, compromising its strength and lifespan.

Extreme Thermal Fluctuations

Pusher plates endure constant and rapid transitions between the hot zone and the quench zone. This extreme thermal cycling induces significant stress, leading to thermal shock and cracking in materials not designed for such conditions.

Mechanical Stress

The plates are subjected to continuous mechanical loading as they convey parts through the furnace. This constant weight and movement demand high flexural strength and resistance to creep, especially at elevated temperatures.

Understanding the Trade-offs

Why Standard Ceramics Fail

Materials suitable for less demanding environments simply cannot withstand the combined assault of chemical reduction, rapid temperature swings, and sustained mechanical stress. Their bonds break down, leading to premature failure.

The Necessity of Specialized Mullite

Mullite, when properly bonded, offers a unique combination of high-temperature strength, thermal shock resistance, and chemical stability in reducing atmospheres. However, achieving this optimal state during manufacturing is complex.

Making the Right Choice for Your Goal

Selecting effective mullite pusher plates requires a clear understanding of these manufacturing and operational challenges.

- If your primary focus is longevity in hydrogen environments: Prioritize manufacturers with proven expertise in achieving robust mullite bonds specifically for reducing atmospheres, often indicating specialized processing techniques.

- If your primary focus is resistance to thermal shock: Seek plates engineered for high thermal cycling stability, often through specific microstructural control to mitigate stress.

- If your primary focus is high load-bearing capacity: Verify the material's flexural strength and creep resistance at operating temperatures, ensuring it can handle the maximum part weight.

Effective mullite pusher plates are a critical component for high-temperature PM sintering furnaces, demanding advanced material science and manufacturing precision.

Summary Table:

| Challenge | Impact on Mullite Pusher Plates |

|---|---|

| Chemical Attack (H₂) | Degrades ceramic structure, reducing strength and lifespan |

| Extreme Thermal Cycling | Causes thermal shock, cracking, and material fatigue |

| Mechanical Loading | Leads to flexural stress and creep at high temperatures |

| Mullite Bonding Difficulty | Compromises structural integrity if not properly formed during manufacturing |

Struggling with pusher plate failures in your hydrogen furnace? KINTEK specializes in high-performance lab equipment and consumables designed to withstand extreme conditions. Our expertise in advanced ceramics ensures your furnace components deliver maximum longevity and reliability. Contact us today to discuss a custom solution for your laboratory's toughest challenges!

Visual Guide

Related Products

- High Temperature Wear-Resistant Alumina Al2O3 Plate for Engineering Advanced Fine Ceramics

- Precision Machined Yttria Stabilized Zirconia Ceramic Plate for Engineering Advanced Fine Ceramics

- Carbon Graphite Plate Manufactured by Isostatic Pressing Method

- Custom-Made Alumina Zirconia Special-Shaped Ceramic Plates for Engineering Advanced Fine Ceramics Processing

- Boron Nitride (BN) Ceramic Plate

People Also Ask

- How do precision ovens or drying equipment affect film quality? Ensure defect-free GPTMS-modified cellulose sensors.

- What improvements have been made to reduce noise in laboratory vacuum pumps? Quieter Operation for a More Productive Lab

- What is the purpose of using adjustable high-temperature fixtures? Ensure Stable Material Interfaces up to 1000°C

- What is the difference between glass tube and quartz tube? A Guide to Thermal & Optical Performance

- Why is an airtight sample holder with a beryllium window required for XRD of sulfide solid electrolytes?

- What role does an ultrasonic cleaner play in specimen pretreatment for supercritical water? Ensure Experimental Purity

- Why are zirconia grinding balls preferred for milling battery cathode or electrolyte powders? Achieve High Purity

- What is the working temperature of quartz glass? Master Its High-Temp Limits & Applications