While a hydraulic press operates on the principle of fluid dynamics, its physical structure is almost entirely composed of high-strength steel. This choice is non-negotiable, as the frame and hydraulic cylinder must be robust enough to withstand the immense internal pressures and external forces generated during operation. The entire design is a testament to containing and directing force through material strength.

A hydraulic press is not made from a single material but is an engineered assembly of components. The material for each part is chosen specifically for its function, with high-strength steel forming the critical structural frame and hydraulic cylinder to safely manage extreme pressures.

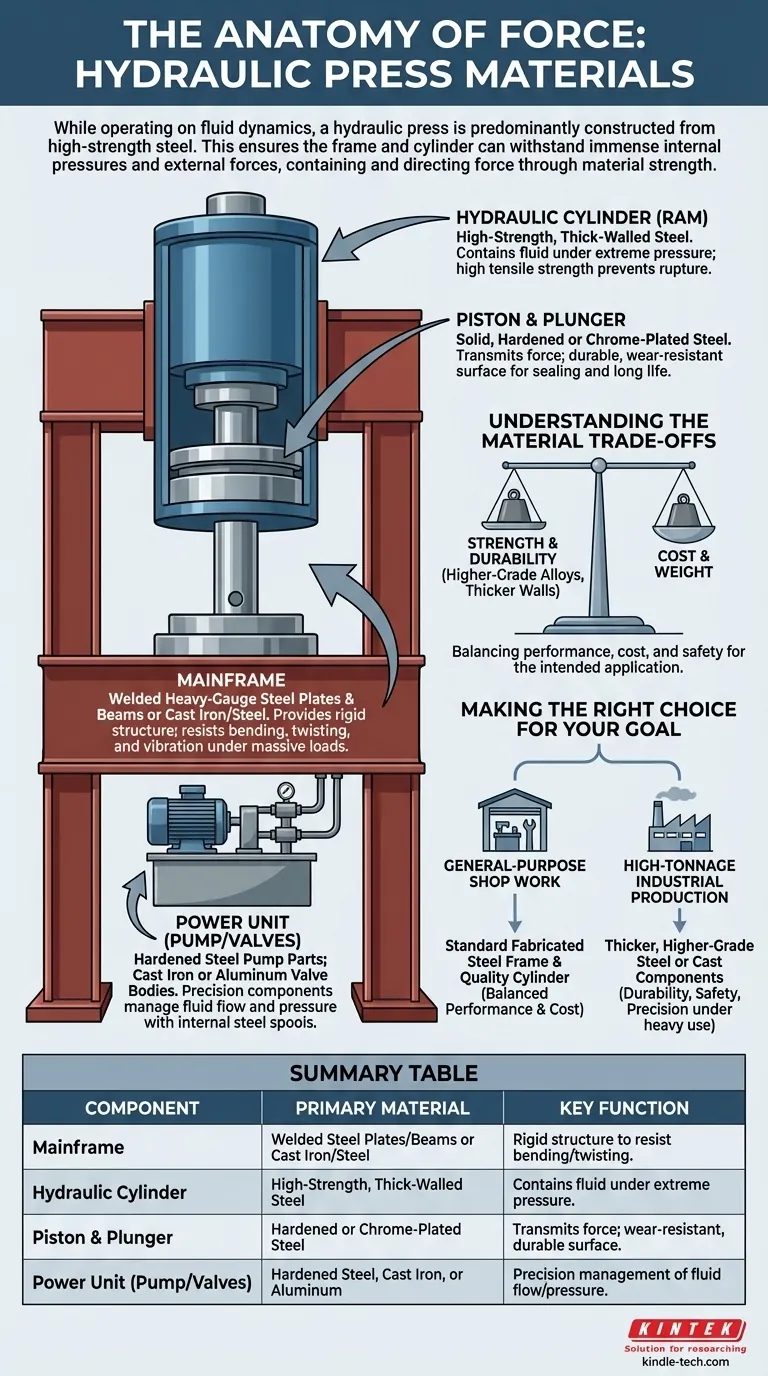

The Anatomy of Force: Key Components and Their Materials

To understand why specific materials are used, we must first break down the hydraulic press into its core functional parts. The machine's ability to multiply force is only as reliable as the materials used to construct it.

The Mainframe

The mainframe is the skeleton of the press. Its sole purpose is to provide a rigid structure that resists bending, twisting, or failing under the massive loads it imposes.

For most shop presses and many industrial versions, this frame is constructed from welded heavy-gauge steel plates and beams. In very large or specialized high-tonnage presses, the frame may be made of cast iron or cast steel to provide superior vibration damping and rigidity.

The Hydraulic Cylinder (Ram)

This is the heart of the press where the force is generated. The cylinder is a sealed tube that must contain hydraulic fluid under extreme pressure, often thousands of pounds per square inch (PSI).

Because of this, the cylinder is invariably machined from high-strength, thick-walled steel. The material must have a high tensile strength to prevent it from rupturing under pressure, making the steel's quality and specifications a critical safety factor.

The Piston and Plunger

The piston (in the large cylinder, or Ram) and the plunger (in the smaller cylinder) are the moving components that transmit force to and from the hydraulic fluid.

These parts are also made of solid steel. They must be durable enough to handle the force and are often heat-treated or chrome-plated to provide a hard, smooth, wear-resistant surface that ensures a proper seal and long operational life.

The Power and Control Systems

The press is powered by a hydraulic power unit, which includes a motor and a pump. The pump itself is a precision device with internal components made of hardened steel to resist wear from continuous operation.

Hydraulic directional control valves, which manage the flow of fluid, are typically housed in cast iron or aluminum bodies with internal steel spools. The material here is chosen for its ability to be precisely machined to prevent leaks.

The Hydraulic Fluid

While not a structural material, the hydraulic fluid (typically a specialized oil) is the medium through which force is transmitted. It is chosen for its incompressibility, thermal stability, and lubricating properties, which are essential for the system to function correctly and efficiently.

Understanding the Material Trade-offs

The choice of materials in a hydraulic press is a careful balance of performance, cost, and safety. There is no single "best" material, only the most appropriate one for the intended application.

Strength vs. Cost

The primary trade-off is between strength and cost. Using higher-grade steel alloys or increasing the thickness of the frame and cylinder walls significantly improves the press's safety and capacity. However, these choices also directly increase the manufacturing cost and weight of the machine.

Cast vs. Fabricated Structures

A fabricated steel frame is versatile and cost-effective for many designs. However, a cast iron or cast steel frame can offer better rigidity and vibration absorption in high-precision or extreme-tonnage applications, though it involves a more complex and expensive manufacturing process.

Wear Resistance and Fatigue

The materials aren't just selected for raw strength. They must also resist fatigue from countless cycles of pressurization and release. This is why components like pistons and valves are made from hardened or treated steel—to prevent premature wear that could lead to system failure.

Making the Right Choice for Your Goal

The materials used in a hydraulic press directly correlate to its intended use case, from a small workshop tool to a massive industrial machine.

- If your primary focus is general-purpose shop work: A press with a standard fabricated steel frame and a quality steel cylinder offers the best balance of performance and cost.

- If your primary focus is high-tonnage industrial production: A press made with thicker, higher-grade steel or cast components is essential for ensuring durability, safety, and precision under continuous heavy use.

Ultimately, the materials of a hydraulic press are a direct reflection of its purpose: to safely contain and precisely control immense physical force.

Summary Table:

| Component | Primary Material | Key Function |

|---|---|---|

| Mainframe | Welded Steel Plates/Beams or Cast Iron/Steel | Provides rigid structure to resist bending and twisting under load. |

| Hydraulic Cylinder (Ram) | High-Strength, Thick-Walled Steel | Contains hydraulic fluid under extreme pressure without rupturing. |

| Piston & Plunger | Hardened or Chrome-Plated Steel | Transmits force; requires a wear-resistant, durable surface. |

| Power Unit (Pump/Valves) | Hardened Steel, Cast Iron, or Aluminum | Precision components that manage hydraulic fluid flow and pressure. |

Need a hydraulic press built with the right materials for your specific application?

The materials used in a hydraulic press are critical to its performance, safety, and longevity. Whether you need a robust press for high-tonnage industrial production or a reliable model for general workshop tasks, KINTEK's expertise ensures you get a machine engineered with the optimal materials for your needs.

We specialize in providing laboratory and industrial equipment, including hydraulic presses designed for durability and precision. Let our team help you select or customize a press that delivers the force and reliability your projects demand.

Contact KINTEL today to discuss your requirements and find the perfect hydraulic press solution!

Visual Guide

Related Products

- Manual Lab Heat Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

People Also Ask

- What is an automatic press machine? High-Precision Force for Modern Manufacturing

- What is the efficiency of a hydraulic press? Harness Unmatched Force Multiplication for Your Lab

- What is a hydraulic press in simple words? Harness Immense Force for Shaping and Crushing

- What is the conclusion of a hydraulic press? Unmatched Force for Industrial Applications

- What does a manual press do? Understand the Two Key Types for Your Lab or Industrial Needs