At their core, high-temperature furnaces are constructed from a specific class of materials known as refractories, which are chosen for their ability to withstand extreme conditions. The furnace body and insulation are typically built from materials like graphite or high-purity ceramics. The components responsible for generating the heat, the heating elements, are made from more specialized materials such as molybdenum, tungsten, silicon carbide, and sometimes platinum.

The choice of material in a high-temperature furnace is not monolithic; it is dictated by function. The furnace's structural integrity and insulation rely on refractory materials that contain heat, while the heating elements are made from conductive materials that can generate extreme temperatures without degrading.

The Furnace Body: Structural Integrity and Insulation

The body of the furnace serves as the primary structure and the first line of defense in containing the intense heat. Its materials must provide physical stability and thermal insulation.

The Role of Refractory Materials

A refractory is any material that can withstand very high temperatures without degrading, melting, or breaking down. It must also resist thermal shock, physical pressure, and chemical attack from the materials being processed.

Common Structural Materials

Ceramics, such as high-purity alumina or zirconia, are excellent insulators and are chemically stable in oxidizing atmospheres. They form the basis for many box and tube furnaces used in laboratory and industrial settings.

Graphite is another common choice, especially for high-vacuum furnaces. It has outstanding strength at high temperatures and excellent thermal stability, but it must be used in a vacuum or inert atmosphere to prevent it from burning.

Heating Elements: The Engine of the Furnace

Heating elements are the active components that convert electrical energy into the thermal energy required to reach process temperatures. Their material selection is critical to furnace performance and longevity.

The Challenge of Generating Extreme Heat

These elements must not only get incredibly hot but also remain stable and conductive at those temperatures. They must resist sagging, warping, and degrading over many thermal cycles.

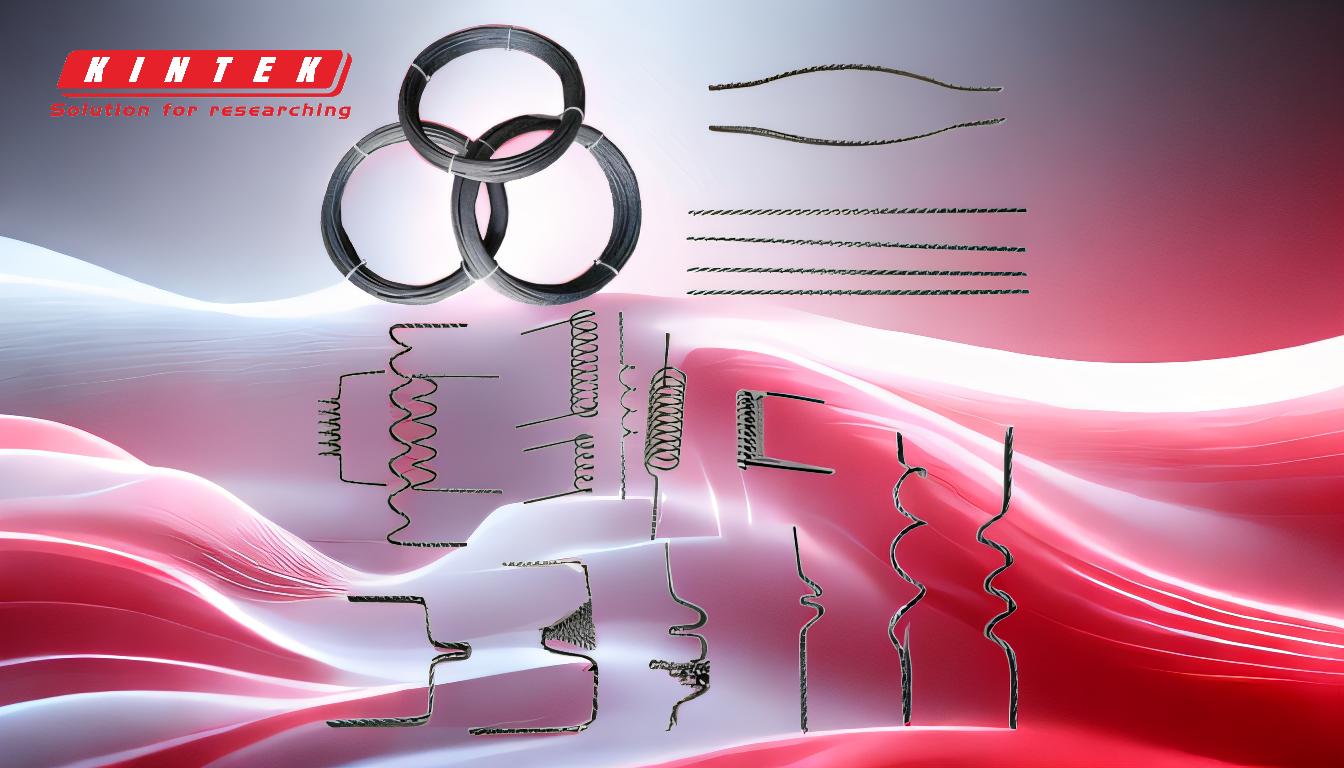

Key Heating Element Materials

Molybdenum (Mo) and Tungsten (W) are refractory metals widely used as heating elements. They offer very high melting points but will oxidize rapidly, meaning they must be operated in a vacuum or a protective, non-oxidizing atmosphere.

Silicon Carbide (SiC) is a ceramic compound that can be used as a heating element in furnaces that operate in air. It is durable and can handle high power loads, making it a versatile choice.

Molybdenum Disilicide (MoSi2) elements are also popular for high-temperature air operation. They form a protective silica layer that allows them to function at very high temperatures without rapid degradation.

Understanding Material Trade-offs and Limitations

The ideal material does not exist. Every choice involves a compromise between performance, cost, and the specific operating environment of the furnace.

Atmosphere Compatibility

This is the most critical trade-off. Graphite, Molybdenum, and Tungsten are superior for vacuum and inert gas environments but will be destroyed in the presence of oxygen at high temperatures.

Conversely, materials like Silicon Carbide and Molybdenum Disilicide are designed specifically for use in air or oxidizing atmospheres, where they form a protective oxide layer.

Cost vs. Maximum Temperature

There is a direct correlation between a material's maximum operating temperature and its cost. Elements like platinum can operate at high temperatures with excellent chemical resistance, but their cost is often prohibitive for general use.

Tungsten offers the highest temperature capability of the common refractory metals but is more expensive and brittle than Molybdenum. This creates a clear cost-performance decision for the furnace designer.

Making the Right Choice for Your Goal

The materials used in a furnace are directly tied to its intended application, from sintering metal powders to growing crystals. Understanding your primary goal will clarify why a certain furnace is built the way it is.

- If your primary focus is ultra-high temperatures in a vacuum: You will be working with a furnace using tungsten or molybdenum heating elements and likely a graphite or all-metal hot zone.

- If you are working with an oxygen-rich atmosphere: Your furnace will use ceramic insulation and heating elements made of materials like silicon carbide or molybdenum disilicide.

- If you need to process highly reactive materials: The furnace will require an extremely inert environment, often using high-purity ceramic liners to prevent any contamination.

- If your goal is cost-effective, general-purpose heating: You will likely encounter a box furnace with a robust ceramic body and durable, cost-efficient heating elements suitable for operation in air.

Ultimately, understanding the function of each component is the key to appreciating why these specific, high-performance materials are essential.

Summary Table:

| Component | Key Materials | Primary Function & Key Property |

|---|---|---|

| Furnace Body & Insulation | Graphite, High-Purity Ceramics (Alumina, Zirconia) | Provides structural integrity and thermal insulation; resists extreme heat and chemical attack. |

| Heating Elements | Molybdenum, Tungsten, Silicon Carbide (SiC), Molybdenum Disilicide (MoSi2) | Generates extreme heat; must remain stable and conductive at high temperatures. |

| Critical Consideration | Atmosphere (Air vs. Vacuum/Inert Gas) | Dictates material choice; some materials oxidize in air, others require protective atmospheres. |

Need a High-Temperature Furnace Tailored to Your Specific Application?

The right materials are critical for your furnace's performance, longevity, and the success of your processes—whether you're sintering, heat treating, or conducting research. KINTEK specializes in lab equipment and consumables, providing expert solutions for all your laboratory needs.

Our team can help you select the perfect furnace with the ideal material configuration (graphite, ceramic, molybdenum, silicon carbide, etc.) for your specific atmosphere and temperature requirements.

Contact us today to discuss your project and let KINTEK provide the reliable, high-performance equipment your lab deserves.

Related Products

- 1400℃ Laboratory Quartz Tube Furnace with Alumina Tube Tubular Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory Quartz Tube Furnace with Alumina Tube Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How do you clean a tube furnace tube? A Step-by-Step Guide to Safe and Effective Cleaning

- What is the difference between a tube furnace and a box furnace? Choose the Right Heat Treatment Process

- What is the high temperature of a tube furnace? Unlock the Right Model for Your Application

- What are the benefits of a tube furnace? Achieve Superior Temperature & Atmosphere Control

- What are the advantages of a tube furnace? Achieve Superior Temperature Uniformity and Control