At its core, a vacuum chamber's material is chosen based on its strength, purity, and how well it contains a vacuum. The most common materials for the chamber body are stainless steel and aluminum alloys. For less demanding applications, plated mild steel is used, while specialized uses can involve glass, ceramic, or acrylic.

The ideal material for a vacuum chamber is not simply the strongest, but the one that best balances structural integrity against atmospheric pressure with minimal contamination of the vacuum itself through leaks or outgassing. This balance is dictated entirely by the application's required vacuum level and operating conditions.

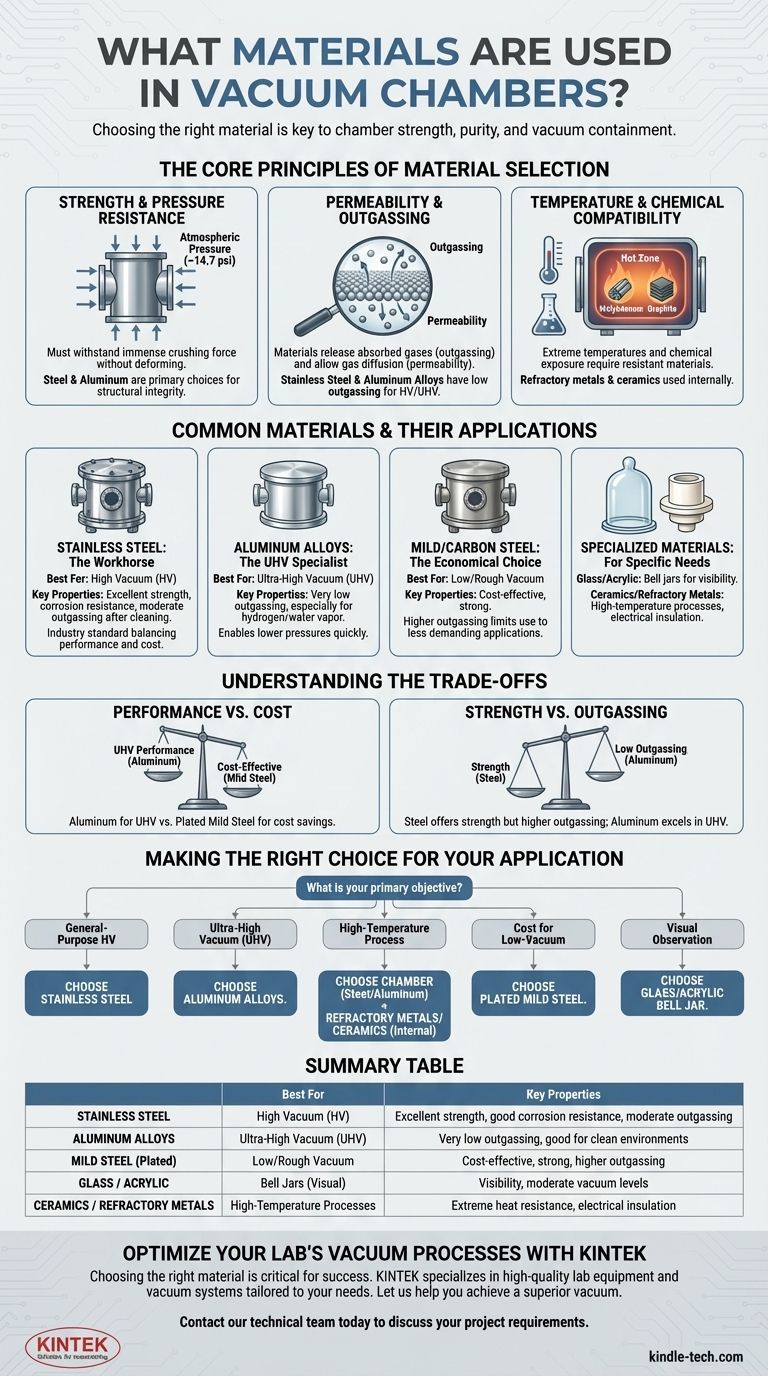

The Core Principles of Material Selection

To understand why certain materials are used, you must first understand the fundamental physics of a vacuum environment. The material isn't just a box; it's an active part of the vacuum system.

Strength and Pressure Resistance

A vacuum chamber must withstand the immense, constant force of atmospheric pressure (about 14.7 pounds per square inch at sea level) trying to crush it. The material must be strong and rigid enough to resist this pressure without deforming, especially for large chambers.

This is why metals like steel and aluminum are primary choices. Their structural integrity ensures the chamber maintains its precise shape, which is critical for many scientific and manufacturing processes.

Permeability and Outgassing

A perfect vacuum is impossible to achieve, in part because the chamber walls themselves release molecules. Outgassing is the slow release of absorbed gases (like water vapor) from a material's surface and bulk. Permeability is the diffusion of gases through the material.

For high and ultra-high vacuum (UHV) systems, these phenomena are the primary enemy. Materials like stainless steel and aluminum alloys are chosen for their low outgassing rates, ensuring the vacuum pump can achieve and hold the target pressure.

Temperature and Chemical Compatibility

Many vacuum processes happen at extreme temperatures. A vacuum furnace, for example, requires internal components that can withstand intense heat without degrading or contaminating the process.

For these applications, refractory metals like molybdenum or materials like graphite are used for internal "hot zones" and hearths. The outer chamber material must also be able to handle the resulting thermal load.

Common Materials and Their Applications

The choice of material is a direct function of the vacuum level and process requirements.

Stainless Steel: The Workhorse

Stainless steel is the most common material for a reason. It offers an excellent balance of strength, low outgassing (after proper cleaning), and corrosion resistance, making it suitable for a wide range of high vacuum (HV) applications.

Aluminum Alloys: The UHV Specialist

For ultra-high vacuum (UHV) systems, aluminum alloys are often preferred. While not as strong as steel, they have a significantly lower outgassing rate, especially for hydrogen and water vapor. This allows pumps to reach much lower pressures more quickly.

Mild/Carbon Steel: The Economical Choice

For applications where a deep vacuum is not the primary goal, plated mild steel is a cost-effective option. It is strong and inexpensive, but its higher outgassing rate limits its use to low or rough vacuum applications. It is often plated with nickel to improve surface properties.

Specialized Materials: For Specific Needs

Materials like glass or acrylic are used for bell jars, where visibility is crucial and the vacuum level is modest. High-density ceramics are used for their electrical insulation and high-temperature properties in specific feedthroughs or component mounts.

Understanding the Trade-offs

No single material is perfect for every situation. The final choice always involves balancing competing factors.

Performance vs. Cost

Aluminum alloys offer superior UHV performance but come at a higher material and fabrication cost than stainless steel. Plated mild steel is the cheapest option but is unsuitable for any application requiring a clean, deep vacuum.

Strength vs. Outgassing

Steel is stronger and more rigid than aluminum, making it a better choice for very large chambers or those under mechanical stress. However, this strength comes at the cost of higher outgassing, disqualifying it for the most demanding UHV applications where aluminum excels.

Machinability and Fabrication

The complexity of the chamber design can also influence material choice. Some materials are easier to machine, weld, and clean than others, which directly impacts the final cost and reliability of the chamber.

Making the Right Choice for Your Application

Your final decision should be guided by your primary objective.

- If your primary focus is general-purpose high vacuum (HV): Stainless steel is the industry standard, offering the best overall balance of performance and cost.

- If your primary focus is ultra-high vacuum (UHV): Aluminum alloys are the superior choice due to their extremely low outgassing properties.

- If your primary focus is a high-temperature process: The chamber may be steel, but internal components will require refractory metals like molybdenum or graphite.

- If your primary focus is cost for a low-vacuum application: Plated mild steel is a viable and economical option.

- If your primary focus is visual observation of a process: A glass or acrylic bell jar is the most practical solution.

Ultimately, selecting the right material is about matching its physical properties to the demands of the vacuum you need to create.

Summary Table:

| Material | Best For | Key Properties |

|---|---|---|

| Stainless Steel | High Vacuum (HV) | Excellent strength, good corrosion resistance, moderate outgassing |

| Aluminum Alloys | Ultra-High Vacuum (UHV) | Very low outgassing, good for clean environments |

| Mild Steel (Plated) | Low/Rough Vacuum | Cost-effective, strong, higher outgassing |

| Glass / Acrylic | Bell Jars (Visual) | Visibility, moderate vacuum levels |

| Ceramics / Refractory Metals | High-Temperature Processes | Extreme heat resistance, electrical insulation |

Optimize Your Lab's Vacuum Processes with KINTEK

Choosing the right vacuum chamber material is critical for the success and reliability of your laboratory processes. Whether you require the ultra-clean environment of an aluminum UHV chamber or the robust strength of a stainless steel HV system, the wrong choice can lead to contamination, slow pump-down times, and process failure.

KINTEK specializes in providing high-quality lab equipment, including vacuum systems and components tailored to your specific needs. We understand the intricate balance between material properties and application requirements. Our experts can help you select the perfect chamber material and configuration to ensure peak performance, efficiency, and longevity for your research or production.

Let us help you achieve a superior vacuum. Contact our technical team today to discuss your project requirements and discover how KINTEK's solutions can enhance your laboratory's capabilities.

Visual Guide

Related Products

- KF ISO Stainless Steel Vacuum Flange Blind Plate for High Vacuum Systems

- Ultra-Vacuum Electrode Feedthrough Connector Flange Power Electrode Lead for High-Precision Applications

- Laboratory Vertical Water Circulating Vacuum Pump for Lab Use

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Custom PTFE Teflon Parts Manufacturer for Hydrothermal Synthesis Reactor Polytetrafluoroethylene Carbon Paper and Carbon Cloth Nano-growth

People Also Ask

- How do you detect a vacuum furnace leak? Master the Methods for Accurate Leak Detection

- What is the difference between a vacuum furnace and an atmosphere furnace? Choose the Right Heat Treatment for Your Materials

- What is a batch furnace? A Guide to Flexible, High-Precision Thermal Processing

- What do sintering temperatures range from? Unlock the Key to Perfect Material Densification

- What is the temperature of the arc in an electric arc furnace? Harnessing Heat Hotter Than the Sun

- What role does a vacuum annealing furnace play in carbon nanostructures? Achieve Superhydrophobic Surface Performance

- What is the primary function of industrial ovens in lignocellulosic waste pretreatment? Maximize Energy Efficiency

- What are sintered components? A Guide to High-Efficiency Metal Parts Manufacturing