When operating a hydraulic press, a specific set of personal protective equipment (PPE) is non-negotiable. The required items include a full face shield, a lab coat or equivalent body covering, application-specific gloves, long pants, and fully enclosed, closed-toe shoes. For tasks involving liquids or chemicals, a splash apron provides an essential additional layer of protection.

The core principle is that standard PPE is not enough. A hydraulic press presents multiple, distinct hazards—impact from ejected materials, crushing forces, and potential fluid injection—requiring a comprehensive system of protection, not just a simple checklist.

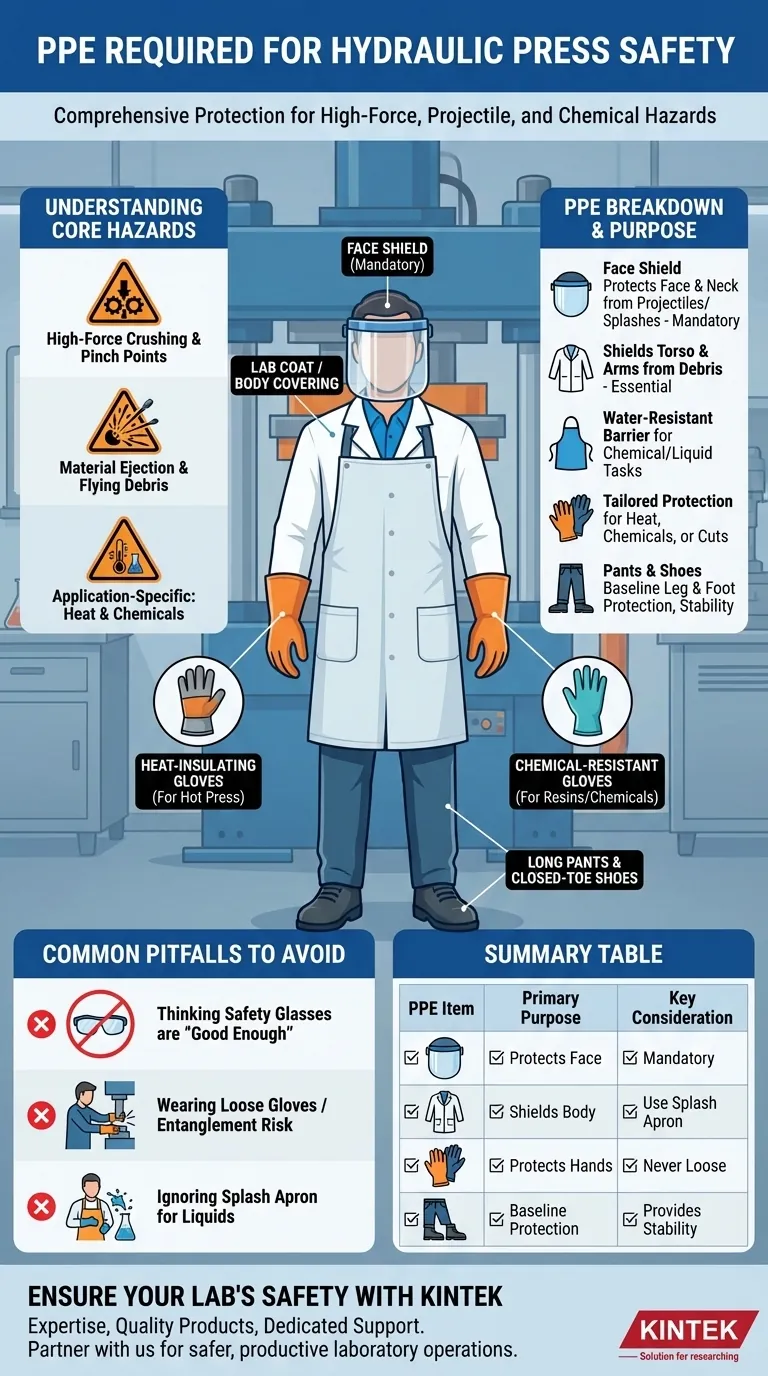

Understanding the Core Hazards of a Hydraulic Press

To properly select PPE, you must first understand the specific dangers you are protecting against. A hydraulic press generates immense, controlled force, which introduces several critical risks beyond simple moving parts.

High-Force Crushing and Pinch Points

This is the most obvious hazard. The immense force exerted between the ram and the press bed can cause catastrophic injury. While PPE offers minimal protection against a direct crushing event, awareness of this primary danger informs all other safety protocols.

Material Ejection and Flying Debris

Materials placed under extreme pressure can fail unexpectedly. They may shatter, fracture, or otherwise eject fragments at high velocity. This is one of the most common causes of serious injury.

Application-Specific Dangers

The workpiece itself introduces unique hazards. Pressing heated materials creates a risk of severe burns, while working with resins, powders, or chemically treated parts can expose you to hazardous substances.

A Breakdown of Required PPE and Its Purpose

Each piece of required equipment is chosen to counter a specific hazard. Viewing them as an interconnected system is the key to effective safety.

Head and Face Protection: The Face Shield

A full face shield is arguably the most critical piece of PPE. Standard safety glasses are insufficient, as they do not protect the face and neck from high-velocity projectiles or splashes.

The face shield serves as the primary barrier against shattered workpieces or tooling.

Body Protection: Lab Coat & Splash Apron

A lab coat, heavy-duty long-sleeve shirt, or equivalent covering protects the arms and torso from flying debris and incidental contact.

For tasks involving oils, chemicals, or other liquids, a splash apron should be worn over the lab coat to provide a water-resistant barrier, preventing chemical absorption and skin contact.

Hand Protection: The Right Gloves for the Job

The type of glove required depends entirely on the application.

If working with heated materials, heat-insulating gloves are mandatory. If working with chemicals or resins, appropriate chemical-resistant gloves are necessary. Never wear standard work gloves that are loose or could become entangled in the press.

Foundational Safety: Long Pants & Closed-Toe Shoes

These items form the baseline of protection in any shop environment.

Long pants shield the legs from debris and splashes. Sturdy, closed-toe shoes, preferably with a reinforced toe, protect the feet from falling objects and provide a stable footing.

Common Pitfalls to Avoid

Understanding common mistakes is just as important as knowing what to do. Inadequate PPE is often a result of underestimating the machine's potential for harm.

Thinking Safety Glasses are "Good Enough"

This is a critical error. The risk of material failure under high pressure means projectiles can come from multiple angles. Only a full face shield provides adequate protection against this primary hazard.

Forgetting the Workpiece Dictates the PPE

The base PPE (face shield, body covering, pants, shoes) is always required. However, operators often forget that the workpiece itself introduces new rules. Always assess the material for heat, chemical, or other hazards and add specialized gloves and aprons accordingly.

Viewing PPE as a Substitute for Machine Guarding

PPE is the last line of defense. The first line is always proper machine guarding, clear work zones, and regular inspection of the press itself, especially its hydraulic lines and fittings.

Making the Right Choice for Your Task

Use this framework to ensure you are properly protected for every job.

- If your primary focus is cold-pressing standard metals or materials: Your absolute minimum is a face shield, lab coat, long pants, and closed-toe shoes.

- If your primary focus is working with heated components (e.g., hot press applications): You must add certified heat-insulating gloves to your standard PPE.

- If your primary focus is pressing materials involving liquids, oils, or chemicals: A splash apron and the correct type of chemical-resistant gloves are mandatory additions to your kit.

Ultimately, treating your PPE as a critical and adaptable system is the key to operating a hydraulic press with confidence and safety.

Summary Table:

| PPE Item | Primary Purpose | Key Consideration |

|---|---|---|

| Full Face Shield | Protects face/neck from high-velocity projectiles | Mandatory; safety glasses are insufficient |

| Lab Coat / Body Covering | Shields torso/arms from flying debris | Use a splash apron for liquid/chemical tasks |

| Application-Specific Gloves | Protects hands from heat or chemicals | Never use loose gloves that can get caught |

| Long Pants & Closed-Toe Shoes | Baseline protection for legs and feet | Provides stability and shields from falling objects |

Ensure Your Lab's Safety with KINTEK

Operating a hydraulic press safely requires the right protective equipment and reliable machinery. At KINTEK, we specialize in providing high-quality lab equipment and consumables, ensuring your operations are not only efficient but also secure.

Why choose KINTEK for your lab safety needs?

- Expertise: We understand the unique hazards of laboratory environments and can recommend the right safety gear and equipment for your specific applications.

- Quality Products: From durable hydraulic presses to essential PPE, we supply equipment you can trust to perform safely under pressure.

- Dedicated Support: Our team is here to help you create a safer lab environment, providing guidance on best practices and optimal equipment use.

Don't compromise on safety. Contact us today to discuss your lab equipment and safety requirements. Let KINTEK be your partner in achieving a safer, more productive laboratory.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.