The most critical precautions for annealing revolve around precise control of the entire thermal cycle: the heating rate, the soaking temperature and time, and especially the cooling rate. Failing to manage any of these three stages will compromise the final properties of the material, negating the purpose of the process.

Annealing is not simply a matter of heating and cooling a material. It is a precise engineering process where success depends on controlling the entire thermal journey to relieve internal stresses and refine the microstructure without introducing new flaws like oxidation or cracking.

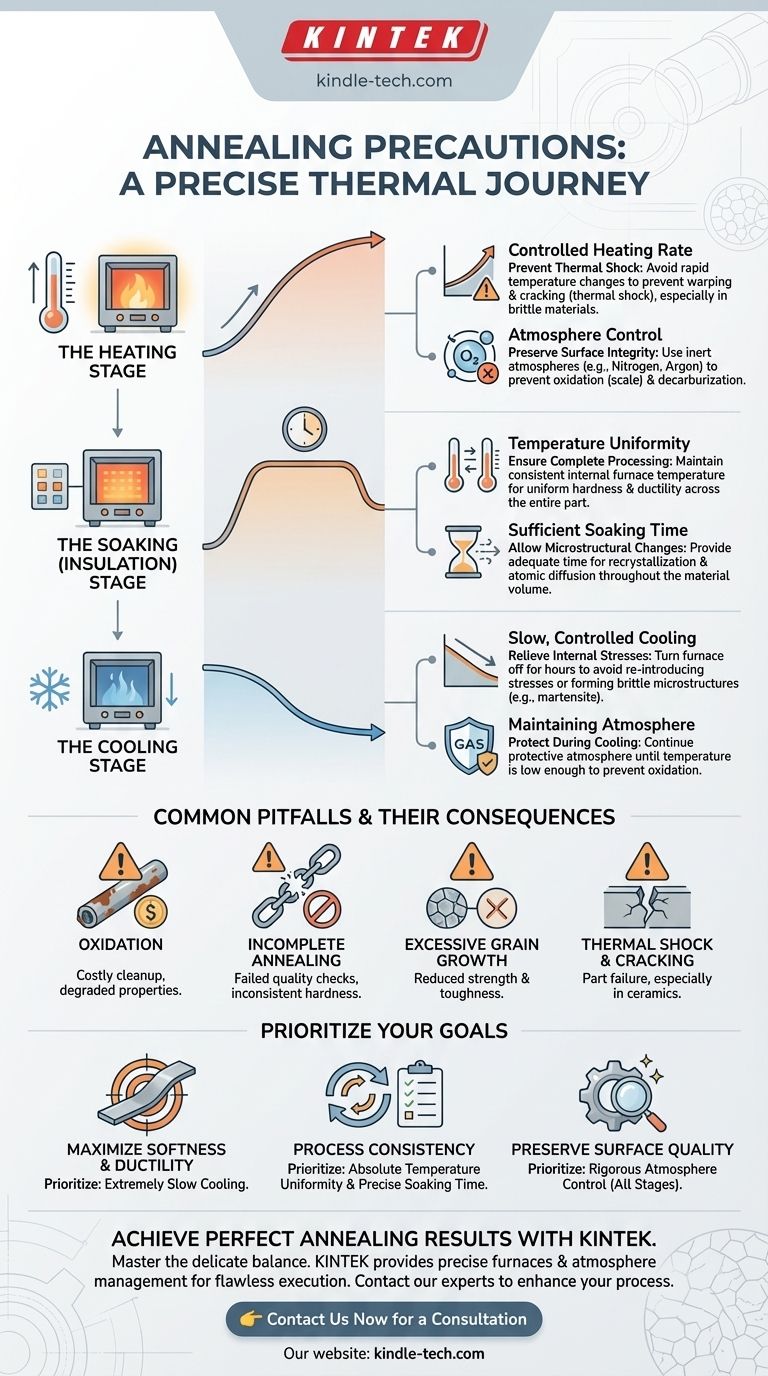

The Three Critical Stages of Annealing

Successful annealing requires careful management of three distinct phases. A precaution taken in one stage can be rendered useless by a mistake in the next.

The Heating Stage

The primary goal here is to bring the material to the target temperature without causing damage.

Controlled Heating Rate: Ramping up the temperature too quickly can create a large thermal gradient between the surface and the core of the part. This induces stress, which can lead to warping or even cracking, a phenomenon known as thermal shock. This is especially critical for brittle materials like ceramics or parts with large, varying cross-sections.

Atmosphere Control: As the material heats up, it becomes more reactive with its environment. For many metals, especially steels, heating in the presence of oxygen will cause oxidation (scale formation) and potentially decarburization (loss of carbon from the surface), which degrades the material's properties. Using a controlled or inert atmosphere (like nitrogen or argon) is a key precaution to preserve the surface finish and integrity.

The Soaking (Insulation) Stage

This is where the intended microstructural changes occur. It requires stability and patience.

Temperature Uniformity: The temperature inside the furnace must be consistent. If parts of the material are cooler than others, the annealing process will be incomplete, resulting in a component with non-uniform hardness and ductility. As the reference material notes, ensuring the entire component reaches and holds the target temperature is vital.

Sufficient Soaking Time: The desired structural changes—such as recrystallization or phase transformations—are not instantaneous. They require time for atomic diffusion to occur throughout the entire volume of the material. A soaking time that is too short will leave the core of the material un-annealed.

The Cooling Stage

This stage is arguably the most defining part of the annealing process and where many failures occur.

Slow, Controlled Cooling: The defining precaution of most annealing processes is a very slow cooling rate. This is often achieved by simply turning the furnace off and letting the part cool down with the furnace over many hours. Rapid cooling can re-introduce internal stresses or, in the case of steel, form hard, brittle microstructures like martensite, which is the exact opposite of the desired outcome.

Maintaining Atmosphere: The material is still hot enough to react with oxygen during the initial phase of cooling. Therefore, the protective atmosphere should be maintained until the temperature drops to a point where oxidation is no longer a significant risk.

Understanding the Trade-offs and Common Pitfalls

Applying these precautions requires balancing competing factors to avoid common process failures.

Pitfall: Oxidation and Scale

This is a direct result of poor atmosphere control during heating and soaking. The resulting surface scale is undesirable and must be removed through costly secondary processes like sandblasting or acid pickling, which can also damage the part.

Pitfall: Incomplete Annealing

This occurs from insufficient soaking time or a temperature that is too low. The material will not achieve the desired softness or internal stress relief, leading to failed quality checks and wasted resources.

Pitfall: Excessive Grain Growth

While sufficient time at temperature is needed, holding the material at a very high temperature for too long can cause its internal grains to grow too large. This can reduce the material's strength and toughness, even though it may be very soft.

Pitfall: Thermal Shock and Cracking

This is the consequence of heating or cooling too rapidly. It is the primary risk for ceramics and a significant concern for metals with complex shapes or drastic changes in thickness.

Making the Right Choice for Your Goal

Your specific goal will determine which precaution you must prioritize.

- If your primary focus is maximizing softness and ductility: You must prioritize an extremely slow and controlled cooling rate, especially through any critical transformation temperatures.

- If your primary focus is process consistency and repeatability: You must prioritize achieving absolute temperature uniformity within the furnace and meticulously controlling the soaking time.

- If your primary focus is preserving surface quality: You must prioritize rigorous atmosphere control to prevent any oxidation or decarburization during the heating, soaking, and initial cooling stages.

By managing these precautions, annealing is transformed from a brute-force heating process into a precise tool for engineering specific material properties.

Summary Table:

| Annealing Stage | Key Precaution | Risk of Neglect |

|---|---|---|

| Heating | Controlled heating rate; use of inert atmosphere | Thermal shock, warping, oxidation, decarburization |

| Soaking | Maintain uniform temperature; sufficient soaking time | Incomplete annealing, non-uniform hardness |

| Cooling | Slow, controlled cooling; maintain atmosphere | Re-introduced stresses, brittle microstructures |

Achieve Perfect Annealing Results with KINTEK

Mastering the delicate balance of heating, soaking, and cooling is essential for successful annealing. KINTEK specializes in providing the precise lab equipment and consumables—including high-quality furnaces with precise temperature control and atmosphere management systems—that your laboratory needs to execute these critical precautions flawlessly.

Ensure your materials achieve the desired softness, ductility, and stress relief without the risks of oxidation, cracking, or inconsistent results. Contact our experts today to discuss how our solutions can enhance your annealing process and deliver reliable, repeatable outcomes.

👉 Contact Us Now for a Consultation

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- How is vacuum heating equipment used for solid-state battery cathodes? Optimize Drying for Superior Battery Performance

- What role does a vacuum drying oven play in processing Al2O3/ZrO2 ceramic mixed slurries? Ensure Powder Quality

- What features are required in high-temperature furnace equipment for the large-scale pyrolysis of nano-packaging particles?

- What is the sintering process of a furnace? A Guide to Solid-State Powder Densification

- What is the annealing temperature of molybdenum? Optimize Your Thermal Processing for Pure Mo & Alloys

- Why is my brazing rod not sticking to copper? Master the 3 pillars for perfect brazing joints

- Is HVAC brazing or soldering? The Critical Choice for Strong, Leak-Free Systems

- What are the factors influencing shrinkage during sintering? Control Dimensional Changes for Precision Parts