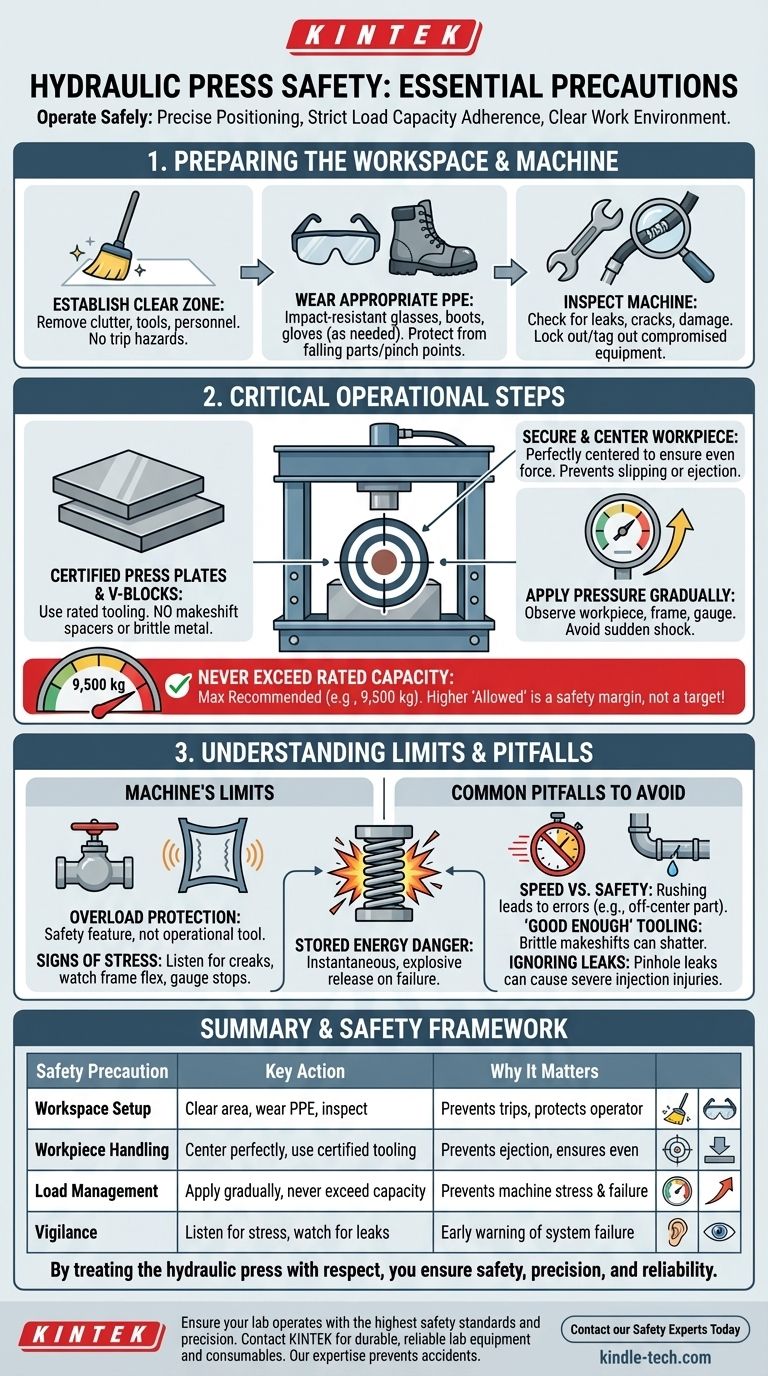

Operating a hydraulic press safely hinges on three core principles: precise positioning of the workpiece, strict adherence to the machine's load capacity, and maintaining a clear and secure work environment. These are not merely suggestions but foundational rules for preventing equipment damage and serious injury.

A hydraulic press concentrates immense force with minimal operator effort. Because of this power, safety is not a list of optional steps but a fundamental, non-negotiable procedure to prevent catastrophic failure of the machine, the workpiece, or—most critically—injury to the operator.

Foundational Safety: Preparing the Workspace

Before any force is applied, the environment and equipment must be properly prepared. Overlooking this stage introduces unnecessary risk.

Establish a Clear Zone

The area around the hydraulic press must be free of clutter, tools, and unnecessary personnel. This eliminates trip hazards and ensures no person or object is inadvertently in a danger zone when the press is under load.

Wear Appropriate Personal Protective Equipment (PPE)

The operator and anyone in the immediate vicinity must wear, at a minimum, impact-resistant safety glasses. Depending on the application, steel-toed boots and heavy-duty gloves may also be necessary to protect against falling parts or pinch points.

Inspect the Machine Before Use

Visually inspect the press before operation. Look for hydraulic fluid leaks on hoses or around fittings, cracks in the frame, or any signs of damage. A compromised machine should be locked out and tagged out until it is repaired by a qualified technician.

The Critical Steps of Operation

How you interact with the press during operation determines both the quality of your work and your personal safety. Every step must be deliberate.

Secure and Center the Workpiece

The most common cause of catastrophic failure is an improperly placed workpiece. The part must be perfectly centered under the ram to ensure force is distributed evenly. An off-center load can cause the workpiece to slip or be ejected from the press at high velocity.

Use Appropriate Press Plates and Blocks

Never press directly on the press bed if possible. Use solid, parallel press plates or certified V-blocks to support the workpiece. These tools must be rated for the tonnage you are applying. Do not use makeshift spacers, sockets, or random pieces of metal, as they can shatter under load.

Apply Pressure Gradually

Apply force slowly and smoothly. Observe the workpiece, the press frame, and the pressure gauge as you operate the pump. A sudden application of pressure can shock the system and the workpiece, leading to unpredictable failure.

Never Exceed Rated Capacity

Every press has a maximum recommended power and a maximum allowed power. For the example specifications, the maximum recommended power is 9,500 kg. This is the operational limit you should never exceed. The higher "maximum allowed" figure (15,200 kg) represents a structural safety margin, not a target. Exceeding the recommended limit stresses the frame and hydraulics, leading to premature wear and failure.

Understanding the Machine's Limits and Features

A hydraulic press is a simple machine with powerful implications. Understanding its design helps you respect its limits.

The Role of Built-in Overload Protection

Many presses have a built-in overload protection valve that prevents the system from generating pressure beyond its design limit. This is a safety feature, not an operational tool. Relying on the overload valve to stop means you have already exceeded the recommended capacity and are operating in a danger zone.

Recognizing Signs of Over-Pressurization

Listen and watch for signs of stress. A frame that is beginning to flex, creaking or groaning sounds, or a pressure gauge that stops moving despite continued pumping are all indicators that you have reached the material's limit or the press's capacity. Stop immediately.

The Danger of Stored Energy

Hydraulic fluid under high pressure is a form of stored energy. If a component like the frame, a block, or the workpiece itself fails, this energy is released instantaneously and explosively. This is why a clear zone and proper centering are not optional.

Common Pitfalls to Avoid

Trust is built on acknowledging potential failures. Avoiding these common mistakes is as important as following the correct procedures.

Speed vs. Safety

Rushing a job is the fastest way to make a critical error, such as failing to properly center a part. The time saved is not worth the risk of a part being violently ejected from the press.

"Good Enough" vs. Correct Tooling

Using an old bearing race or a random block of steel as a spacer is a significant gamble. These items are often made of hardened, brittle metal that can shatter like glass when subjected to tonnage. Always use tooling designed for pressing.

Ignoring Small Leaks

A minor hydraulic fluid leak may seem like a simple nuisance, but it is a symptom of a system integrity problem. Furthermore, a pinhole leak can eject fluid at a velocity high enough to penetrate skin, causing a severe injection injury that requires immediate medical attention.

A Safety-First Framework for Press Operations

Your approach to using a hydraulic press should be dictated by your primary goal.

- If your primary focus is operator safety and training: Enforce a mandatory, repeatable pre-operation checklist that includes workspace inspection, PPE, and machine integrity checks.

- If your primary focus is machine longevity and maintenance: Strictly adhere to the recommended load capacity and implement a regular inspection schedule for hydraulic leaks and frame fatigue.

- If your primary focus is achieving accurate and repeatable results: Master the art of perfectly centering and supporting the workpiece, as this is the only way to ensure even and predictable force application.

By treating the hydraulic press with the respect its power demands, you ensure safety, precision, and reliability in every operation.

Summary Table:

| Safety Precaution | Key Action | Why It Matters |

|---|---|---|

| Workspace Setup | Clear area, wear PPE, inspect machine | Prevents trips, protects operator, identifies hazards |

| Workpiece Handling | Center perfectly, use certified tooling | Prevents ejection, ensures even force distribution |

| Load Management | Apply pressure gradually, never exceed rated capacity (e.g., 9,500 kg) | Prevents machine stress and catastrophic failure |

| Vigilance | Listen for stress sounds, watch for leaks | Early warning signs of over-pressurization or system failure |

Ensure your lab operates with the highest safety standards and precision. KINTEK specializes in durable, reliable lab equipment and consumables, including hydraulic presses designed for safety and longevity. Our expertise helps laboratories like yours prevent accidents and maintain efficient workflows. Contact our safety experts today to find the right press for your needs and get expert guidance on safe operation.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Manual Lab Heat Press

People Also Ask

- What are mechanical presses used for? Achieve High-Speed Stamping and Precision Metal Forming

- What are the advantages of power press? Achieve High-Speed, Low-Cost Mass Production

- What materials are used in a hydraulic press? High-Strength Steel for Maximum Force and Durability

- How much force can a hydraulic press generate? Unlock Massive Power from 1 to 80,000+ Tons

- Can you overload a hydraulic press? Understanding the Critical Risks and Consequences

- How do laboratory hydraulic presses and molds ensure accuracy in high-strength gypsum concrete testing?

- What is the ratio of KBr to drug substance for FTIR analysis? Achieve Perfect Sample Preparation for Clear Spectra

- What are the types of hydraulic press? Find the Right Press for Your Application