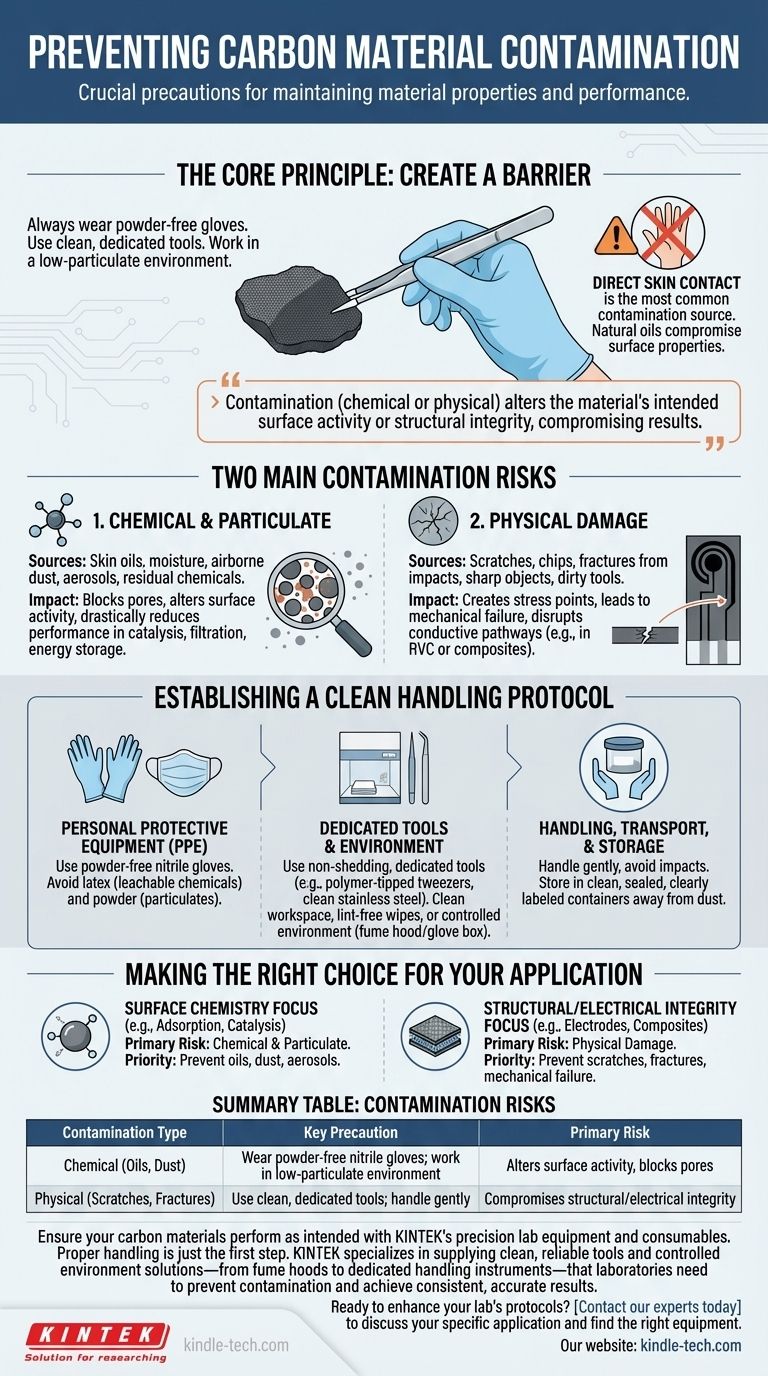

To prevent contamination of carbon materials, you must create a barrier between the material and any potential contaminants. The most critical precautions are to always wear powder-free gloves, use clean, dedicated tools for handling, and work in a low-particulate environment. Direct contact with bare skin is the most common source of contamination, as natural oils will immediately compromise the material's surface properties.

The core challenge in handling carbon materials is not just avoiding dirt, but preserving their engineered properties. Contamination is anything—chemical or physical—that alters the material's intended surface activity or structural integrity, thereby compromising the results of your work.

The Two Categories of Contamination Risk

Every precaution is designed to mitigate two fundamental types of contamination: chemical and physical. Understanding both is crucial for maintaining the material's performance characteristics.

Preventing Chemical and Particulate Contamination

The most immediate threat to carbon materials is chemical contamination from organic residues. The oils, salts, and moisture from your skin are highly effective at altering a carbon surface.

Airborne dust, aerosols, or residual chemicals from unclean work surfaces can also settle on the material, blocking pores and deactivating its surface.

The Impact on Surface Activity

Many advanced carbon materials, such as activated carbon or graphite, are used because of their incredibly high surface area and specific surface chemistry.

When contaminants like skin oils coat this surface, they effectively block the pores and active sites. This can drastically reduce the material's performance in applications like catalysis, filtration, or electrochemical energy storage.

Understanding the Hidden Risks

Effective handling goes beyond simply wearing gloves. You must be aware of less obvious sources of contamination that can silently sabotage your work.

Beyond Skin Oils: Unseen Contaminants

While skin oil is a primary concern, other sources are just as damaging. Cross-contamination from dirty tools, residues from cleaning agents, or even fibers from clothing can be introduced.

Always use tools that are dedicated solely to your carbon materials and have been thoroughly cleaned. For highly sensitive work, operating in a fume hood or glove box provides an essential layer of control.

The Threat of Physical Damage

Contamination is not purely chemical. Physical damage—such as scratches, chips, or fractures—is a form of contamination that irreversibly alters the material's properties.

This is especially critical for structured carbons like Reticulated Vitreous Carbon (RVC) or carbon fiber composites. A scratch can create a stress concentration point leading to mechanical failure or disrupt a conductive pathway in an electrode.

Establishing a Clean Handling Protocol

A standardized protocol is the only way to ensure consistency and prevent accidental contamination.

Personal Protective Equipment (PPE)

Your first line of defense is proper PPE. Always wear powder-free nitrile gloves, as latex can contain leachable chemicals and powder can introduce particulates.

Dedicated Tools and Work Environment

Use non-shedding, clean tools, such as polymer-tipped tweezers or freshly cleaned stainless steel instruments. Never use the same tools that have handled other chemicals or materials without rigorous cleaning.

Your workspace should be clean and uncluttered. For maximum protection, work on a lint-free wipe or in a controlled environment like a cleanroom or a glove box.

Handling, Transport, and Storage

Handle all carbon materials gently. Avoid impacts, excessive pressure, or contact with sharp objects that could cause physical damage.

When not in use, store materials in clean, sealed, and clearly labeled containers to protect them from airborne dust and accidental contact.

Making the Right Choice for Your Application

The stringency of your precautions should match the sensitivity of your application.

- If your primary focus is surface chemistry (e.g., adsorption, catalysis): Your absolute priority is preventing chemical and particulate contamination from oils, dust, and aerosols.

- If your primary focus is structural or electrical integrity (e.g., electrodes, composites): You must be equally vigilant about preventing physical damage, as scratches and fractures are critical failure points.

Ultimately, proper handling is the foundational step toward achieving reliable and repeatable results with carbon materials.

Summary Table:

| Contamination Type | Key Precaution | Primary Risk |

|---|---|---|

| Chemical (Oils, Dust) | Wear powder-free nitrile gloves; work in low-particulate environment | Alters surface activity, blocks pores |

| Physical (Scratches, Fractures) | Use clean, dedicated tools; handle gently | Compromises structural/electrical integrity |

Ensure your carbon materials perform as intended with KINTEK's precision lab equipment and consumables.

Proper handling is just the first step. KINTEK specializes in supplying the clean, reliable tools and controlled environment solutions—from fume hoods to dedicated handling instruments—that laboratories need to prevent contamination and achieve consistent, accurate results with sensitive materials like activated carbon, graphite, and composites.

Ready to enhance your lab's protocols? Contact our experts today to discuss your specific application and find the right equipment to protect your materials and your research.

Visual Guide

Related Products

- Glassy Carbon Sheet RVC for Electrochemical Experiments

- Graphite Vacuum Continuous Graphitization Furnace

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Versatile PTFE Solutions for Semiconductor and Medical Wafer Processing

People Also Ask

- What are the functions of a glassy carbon electrode in CV testing of antioxidants? Enhance Your Redox Analysis Accuracy

- What are the fundamental characteristics of glassy carbon? Discover its Unique Synergy of Properties

- What is an RVC glassy carbon sheet? A High-Performance Material for Demanding Applications

- What is the applicable potential range for an RVC glassy carbon sheet? Master Your Electrochemical Analysis

- What actions and conditions are strictly prohibited when working with a glassy carbon sheet? Protect Your Investment and Data Integrity