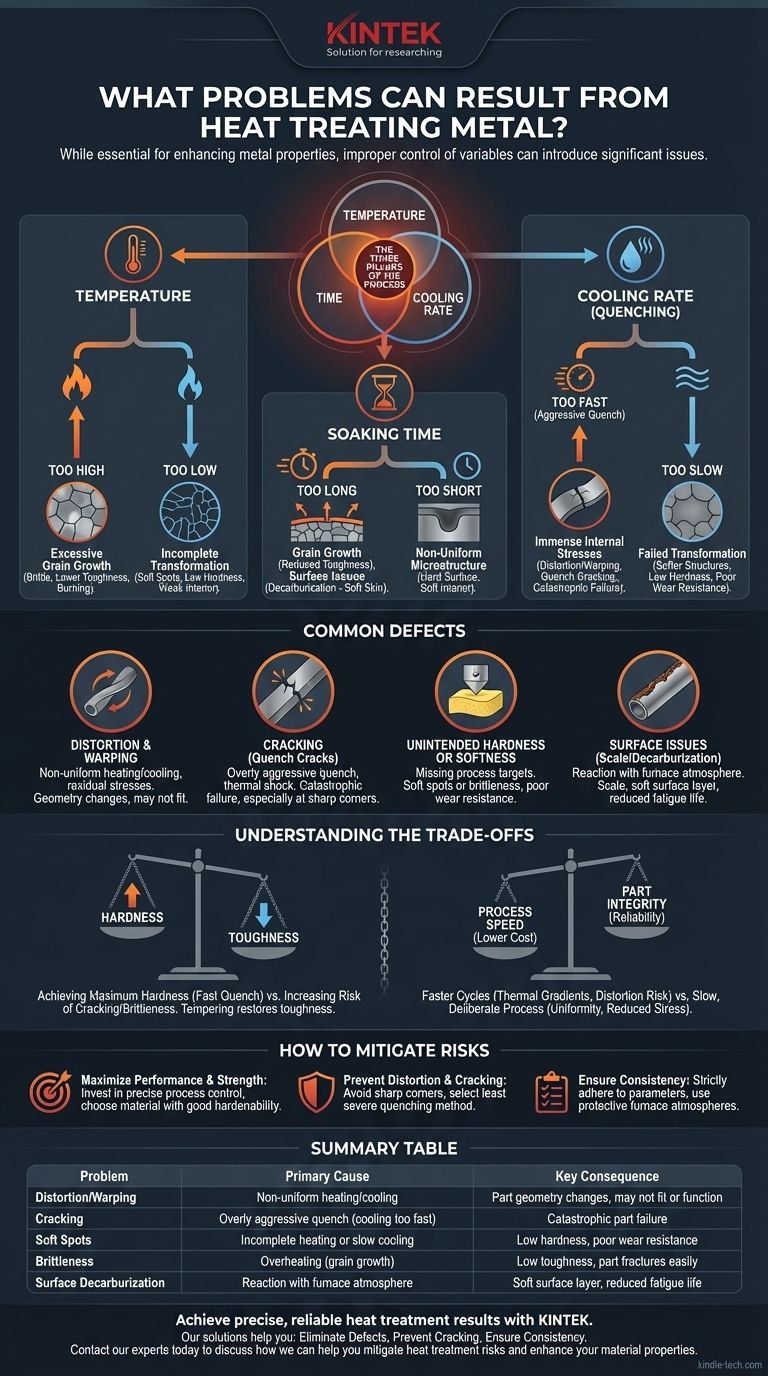

While heat treatment is essential for enhancing metal properties, it is a process of controlled transformation that can introduce significant problems if not managed with precision. The most common issues resulting from improper heat treatment include dimensional distortion, cracking, unintended soft or brittle spots, and detrimental surface changes like decarburization. These failures are almost always a direct consequence of incorrect control over the process variables.

The core principle to understand is that heat treatment problems are not random. They are predictable outcomes caused by a mismatch between the three process variables—temperature, time, and cooling rate—and the specific material and geometry of the part being treated.

The Three Pillars of the Process and Their Risks

Every heat treatment cycle is defined by how a part is heated, how long it is held at temperature, and how it is cooled. An error in any of these three stages will compromise the final result.

The Role of Temperature

Heating a metal part is what enables its internal crystal structure (microstructure) to change. The target temperature must be precise.

- Heating Too High: Exceeding the specified temperature can cause excessive grain growth. Large grains can make the metal brittle and lower its toughness, even if it is hard. In extreme cases, it can lead to overheating or burning, which permanently damages the material.

- Heating Too Low: Failing to reach the required transformation temperature means the desired microstructural change will not fully occur. This typically results in "soft spots" or a part that fails to achieve its target hardness and strength.

The Importance of Soaking Time

Once at the target temperature, the part must be held there for a specific period, known as soaking. This allows the temperature to become uniform throughout the entire part, from the surface to the core.

- Soaking Too Short: If the soaking time is insufficient, the core of the part may not reach the full transformation temperature. This leads to a non-uniform microstructure, with a hard surface but a soft, weak interior.

- Soaking Too Long: Excessive time at high temperatures can also promote grain growth, reducing toughness. It also increases the risk of surface problems like decarburization, where carbon leaches out of the surface, making it soft and prone to wear.

The Critical Nature of Cooling (Quenching)

The cooling phase is often the most stressful stage for a metal part and the most common source of catastrophic failure. The rate of cooling locks in the desired microstructure.

- Cooling Too Fast: An overly aggressive quench (e.g., plunging a hot part into cold water) creates immense internal stresses due to rapid, non-uniform contraction. If these stresses exceed the material's strength, it will result in distortion (warping) or quench cracking.

- Cooling Too Slow: A slow quench may fail to "trap" the desired hard structure (like martensite in steel). The microstructure instead transforms into softer, weaker forms, and the part will not meet its required hardness specifications.

Common Defects Explained

These process errors manifest as specific, identifiable defects in the final product.

Distortion and Warping

This change in a part's geometry is caused by non-uniform heating or cooling, which creates uneven thermal expansion and contraction. It can also be caused by the release of residual stresses locked in from previous manufacturing steps.

Cracking

Quench cracks are the most severe defect. They typically occur when a part with sharp corners, drastic changes in thickness, or high internal stress is cooled too quickly. The thermal shock is simply too much for the material to withstand.

Unintended Hardness or Softness

This is a direct result of missing the process targets. Soft spots occur from incomplete heating or slow cooling, while unexpected brittleness can be caused by overheating (grain growth) or an overly aggressive quench without proper tempering afterward.

Surface Issues

When heated, the metal's surface reacts with the furnace atmosphere. This can cause scale (oxidation on the surface) or decarburization (loss of carbon from the surface layer of steel), leaving the part with a soft, ineffective "skin."

Understanding the Trade-offs

Choosing a heat treatment process is a balancing act. Improving one property can often increase the risk of a specific defect.

Hardness vs. Toughness

Achieving maximum hardness usually requires a very fast quench. However, this aggressive cooling dramatically increases the risk of cracking and results in a very brittle part. This is why a secondary heat treatment process, tempering, is almost always performed to restore some toughness, albeit at the cost of a small reduction in hardness.

Process Speed vs. Part Integrity

Faster heating cycles and shorter soak times can reduce processing costs. However, rushing the process increases the thermal gradients within the part, raising the risk of distortion and leaving the core untreated. A slow, deliberate process ensures uniformity and reduces internal stress, leading to a more reliable part.

How to Mitigate Heat Treatment Risks

Your strategy for preventing problems depends on your primary goal for the component.

- If your primary focus is maximizing performance and strength: Invest in precise process control with calibrated furnaces and choose a material with good hardenability for your desired cross-section.

- If your primary focus is preventing distortion and cracking: Ensure part designs avoid sharp internal corners and abrupt changes in thickness, and select the least severe quenching method that can still achieve the required properties.

- If your primary focus is ensuring batch-to-batch consistency: Document and strictly adhere to proven process parameters, and use protective atmospheres in the furnace to prevent surface decarburization and scale.

Ultimately, mastering heat treatment comes from understanding that it is a process of controlled change, where every variable has a predictable consequence.

Summary Table:

| Problem | Primary Cause | Key Consequence |

|---|---|---|

| Distortion/Warping | Non-uniform heating/cooling | Part geometry changes, may not fit or function |

| Cracking | Overly aggressive quench (cooling too fast) | Catastrophic part failure |

| Soft Spots | Incomplete heating or slow cooling | Low hardness, poor wear resistance |

| Brittleness | Overheating (grain growth) | Low toughness, part fractures easily |

| Surface Decarburization | Reaction with furnace atmosphere | Soft surface layer, reduced fatigue life |

Achieve precise, reliable heat treatment results with KINTEK.

Heat treatment problems like cracking, warping, and inconsistent hardness are directly tied to process control and equipment performance. KINTEK specializes in advanced lab furnaces, temperature control systems, and consumables that provide the uniform heating, accurate soaking, and controlled cooling rates essential for successful metal treatment.

Our solutions help you:

- Eliminate Defects: Precise temperature control and uniform heating minimize distortion and soft spots.

- Prevent Cracking: Optimize quenching processes with reliable equipment.

- Ensure Consistency: Achieve batch-to-batch repeatability for critical components.

Whether you are developing new alloys or processing high-performance parts, KINTEK's expertise in lab equipment ensures your heat treatment processes are robust and reliable.

Contact our experts today to discuss how we can help you mitigate heat treatment risks and enhance your material properties.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What gas does pyrolysis produce? A Fuel Gas Mixture for Energy & Sustainability

- What role does a laboratory vacuum drying oven play in processing nanoparticle powder samples? Protect Sample Integrity

- Why is a vacuum drying oven necessary for cathode composites? Ensure Battery Safety and Interfacial Performance

- What is a vacuum sintering furnace? Unlock Purity and Performance in Advanced Materials

- What is the function of a high temperature furnace? Transform Materials with Precision Heat

- How does a vacuum heat treatment work? Achieve Superior Material Properties in a Pristine Environment

- Why Use Vacuum Furnaces for MAX Phase Cladding? Achieve High Purity & Superior Oxidation Resistance

- What are the factors influencing shrinkage during sintering? Control Dimensional Changes for Precision Parts