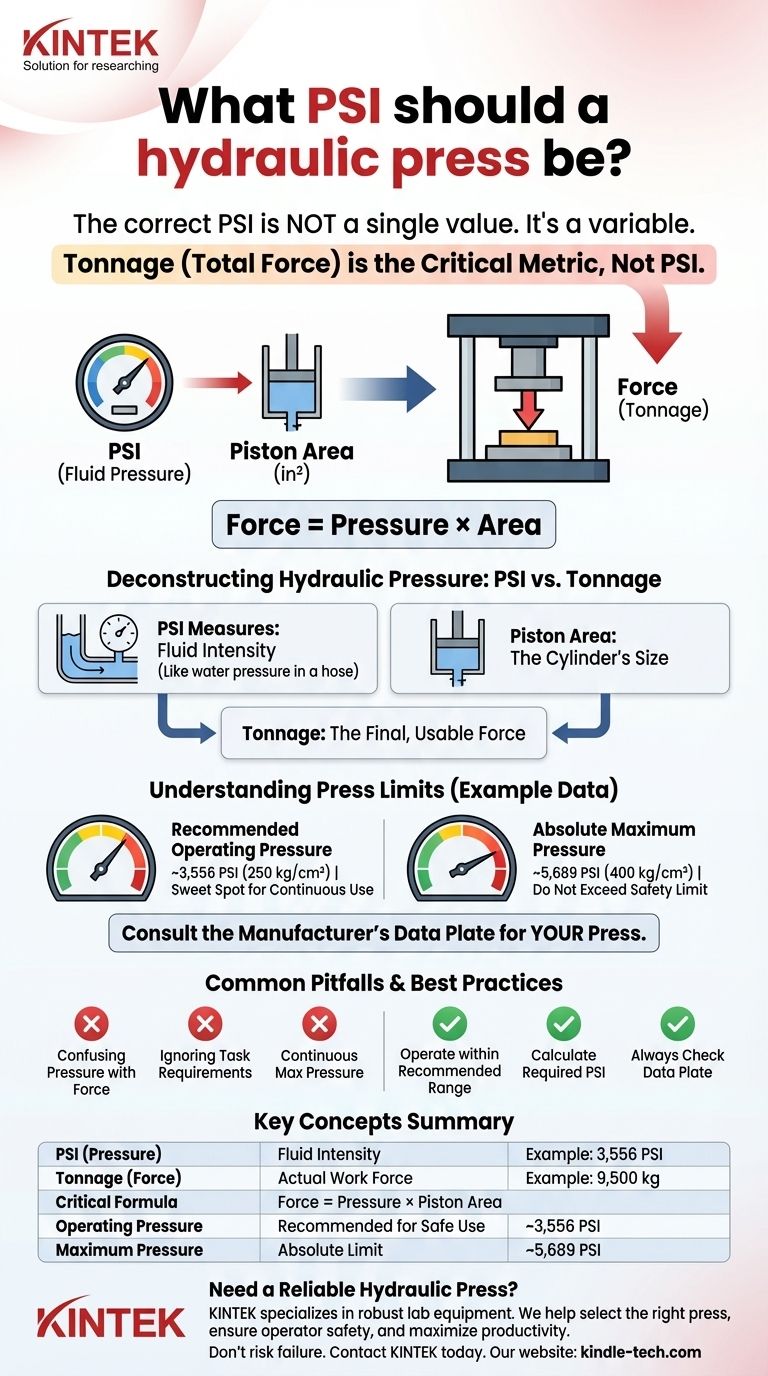

The correct PSI for a hydraulic press is not a single value; it is a variable that depends entirely on the press's design and the force required for the specific task. For the example press cited, the recommended operating pressure is approximately 3,556 PSI (250 kg/cm²), with an absolute maximum of 5,689 PSI (400 kg/cm²). However, focusing only on PSI is a common and critical mistake.

The central takeaway is that tonnage (total force) is the critical metric, not PSI. The PSI of the hydraulic fluid is merely one component of an equation, where Force = Pressure × Area. Understanding this relationship is essential for operating a press safely and effectively.

Deconstructing Hydraulic Pressure: PSI vs. Tonnage

To operate a hydraulic press correctly, you must understand the distinction between the pressure in the system (PSI) and the force it exerts (tonnage).

What PSI Actually Measures

PSI, or pounds per square inch, measures the pressure of the hydraulic fluid being pushed by the pump. It represents the intensity of the fluid.

This pressure reading on the gauge does not tell you the total force the press is applying. It is only one part of the force calculation.

The Role of the Cylinder Piston

The press's hydraulic cylinder contains a piston of a specific size (area). The fluid pressure (PSI) acts upon the entire surface area of this piston.

Think of it like this: the same water pressure from a tap will exert a gentle force through a small squirt gun nozzle but a much greater force through a wide fire hose. The PSI is the water pressure, and the nozzle/hose opening is the piston area.

Why Tonnage is the Critical Metric

Tonnage is the final, usable force exerted by the ram, and it's what actually performs the work, whether it's crushing a car or forming a sheet of metal.

The formula is simple: **Force (Tonnage) = Fluid Pressure (PSI) × Piston Area (in²) **. A press with a large piston can generate immense tonnage with relatively low PSI, while a press with a small piston requires extremely high PSI to achieve the same force.

Understanding the Limits of Your Press

Every hydraulic press has carefully engineered pressure limits that must be respected to ensure safety and equipment longevity. These are typically provided by the manufacturer.

The Recommended Operating Pressure

For the press in the reference data, the recommended limit is 9,500 kg of force, achieved at a pressure of 250 kg/cm² (approximately 3,556 PSI).

Operating at or below this level is the "sweet spot" for continuous use. It ensures the machine runs efficiently without undue stress on its seals, hoses, and pump.

The Absolute Maximum Pressure

The absolute maximum allowed power for the same press is 15,200 kg of force, which corresponds to 400 kg/cm² (approximately 5,689 PSI).

This is a "do not exceed" safety limit. Pushing the press to this pressure risks damaging components or, in the worst case, causing a catastrophic failure of a hydraulic line or cylinder.

Consulting the Manufacturer's Data Plate

The values above are only for one specific machine. Always locate the data plate or manual for the press you are using. This plate is the ultimate source of truth and will specify the rated tonnage and maximum system PSI.

Common Pitfalls to Avoid

Misunderstanding the principles of hydraulic force can lead to damaged equipment, ruined workpieces, and serious safety hazards.

Confusing Fluid Pressure with Work Force

The most common mistake is assuming the PSI on the gauge is the final measure of power. This leads operators to either apply far too little force or, more dangerously, far too much.

Ignoring Material and Task Requirements

Different operations require different forces. Lightly pressing a powder requires a fraction of the force needed to forge a steel billet. Using maximum force for a delicate job will destroy the workpiece.

Operating Continuously at Maximum Pressure

Consistently running a press at its absolute maximum pressure is like redlining a car engine everywhere you go. Even if it doesn't fail immediately, you will drastically shorten the lifespan of the pump, seals, and hydraulic hoses.

How to Determine the Right Pressure for Your Task

Your approach should be dictated by your primary goal, whether it's protecting the equipment or achieving a specific outcome.

- If your primary focus is equipment longevity and safety: Operate within the manufacturer's recommended pressure range, which for the press cited is around 3,556 PSI (250 kg/cm²).

- If your primary focus is achieving a specific force for a task: Calculate the required PSI based on the press's known cylinder area and the target tonnage, ensuring you never exceed the absolute maximum pressure.

- If you are unsure of the press's specifications: Stop and locate the manufacturer's data plate. Never operate a press without knowing its rated force and maximum system pressure.

Ultimately, mastering your hydraulic press means shifting your focus from the gauge's PSI to the actual force you are applying to the work.

Summary Table:

| Key Concept | Description | Example from Article |

|---|---|---|

| PSI (Pressure) | Measures hydraulic fluid intensity. | Gauge reading of 3,556 PSI. |

| Tonnage (Force) | The actual work force applied by the ram. | 9,500 kg of force for a specific task. |

| Critical Formula | Force = Pressure × Piston Area | A larger piston area generates more force at the same PSI. |

| Operating Pressure | Recommended pressure for safe, continuous use. | ~3,556 PSI (250 kg/cm²). |

| Maximum Pressure | Absolute "do not exceed" limit to prevent failure. | ~5,689 PSI (400 kg/cm²). |

Need a Reliable Hydraulic Press for Your Lab or Workshop?

Operating machinery safely and effectively requires the right equipment. KINTEK specializes in providing robust and precise lab equipment, including hydraulic presses designed for consistent performance and user safety.

We can help you:

- Select the right press with the correct tonnage for your specific applications, from material testing to sample preparation.

- Ensure operator safety with equipment that features clear specifications and built-in safety limits.

- Maximize your productivity with reliable machinery that delivers accurate force for repeatable results.

Don't risk equipment failure or inaccurate results. Let our experts help you find the perfect hydraulic press for your needs.

Contact KINTEK today for a consultation and discover how our laboratory solutions can enhance your workflow.

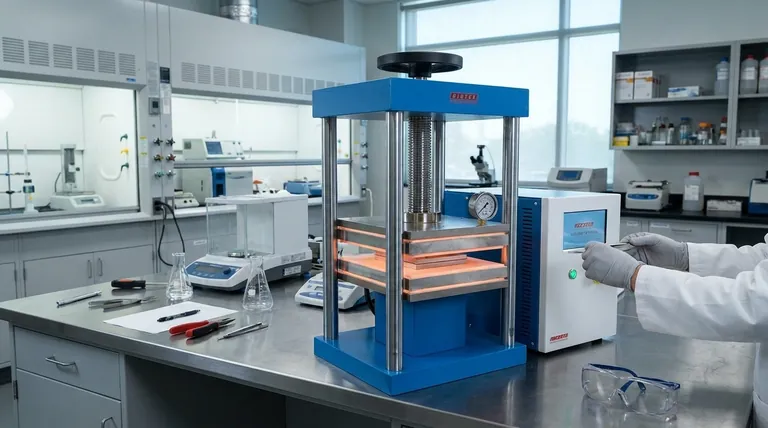

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Laboratory Heat Press Machine

People Also Ask

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples