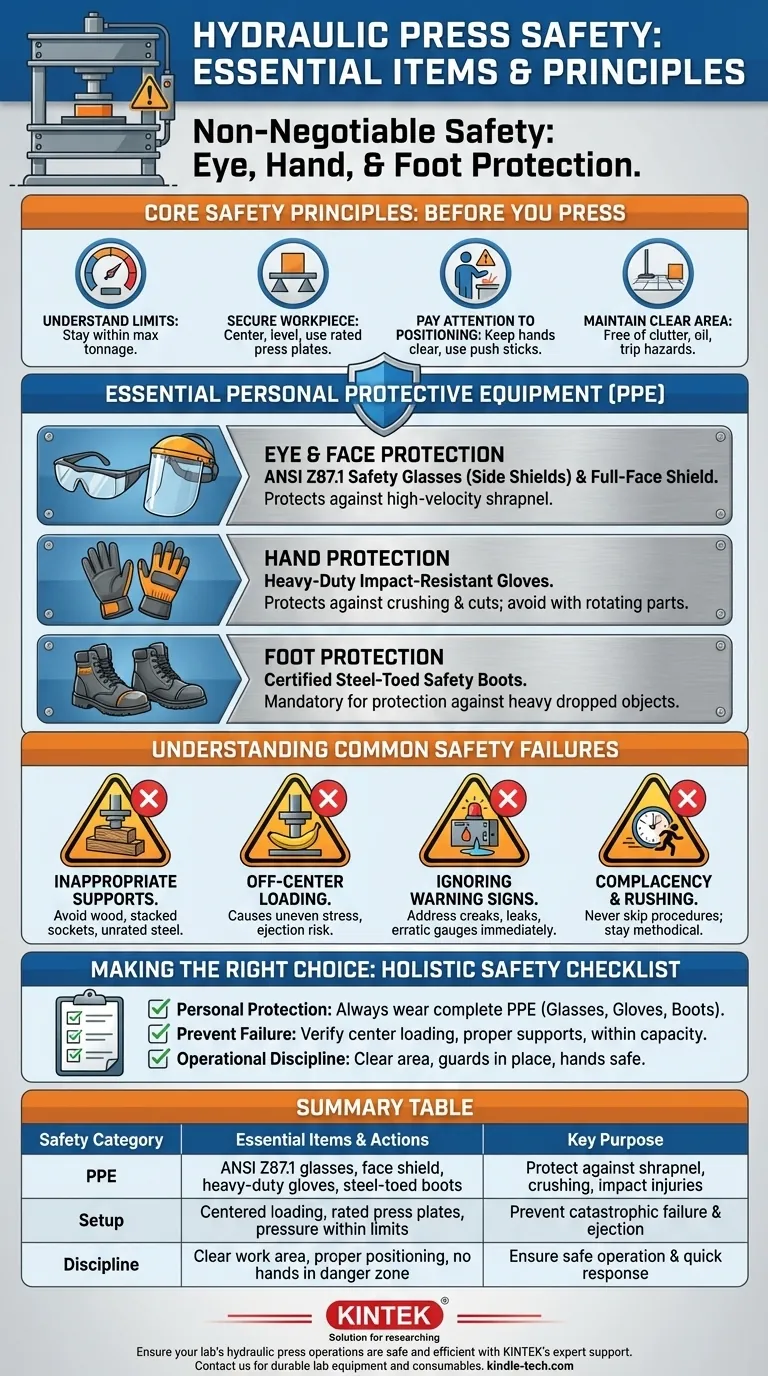

When operating a hydraulic press, your non-negotiable safety items are eye protection, hand protection, and foot protection. The immense force generated by these machines can turn a poorly secured workpiece or a failing component into a high-velocity projectile. Never approach a press without wearing, at a minimum, ANSI Z87.1-rated safety glasses, heavy-duty work gloves, and steel-toed boots.

True hydraulic press safety extends beyond personal equipment. It is a system that combines the right gear with a deep understanding of the machine's force, correct workpiece setup, and a disciplined operational procedure.

Core Safety Principles: Before You Press

Personal Protective Equipment (PPE) is your last line of defense. The first line of defense is a safe and methodical approach to setting up the machine and the workpiece for the task at hand.

Understand the Machine's Limits

Every press has a maximum tonnage rating. Exceeding this limit can cause catastrophic failure of the frame or hydraulic system. Always be aware of the pressure you are applying and stay well within the machine's specified capabilities.

Secure the Workpiece Correctly

A significant number of press-related injuries occur because the workpiece was not stable. It must be centered, level, and supported by appropriate press plates or V-blocks that can handle the load without deforming.

Pay Attention to Positioning

Your body positioning is critical. Never place any part of your body, especially your hands, between the ram and the workpiece. Use push sticks or other tools to make adjustments, and always keep your hands clear of the "danger zone."

Maintain a Clear Work Area

The area around the hydraulic press must be free of clutter, oil spills, and trip hazards. This ensures you have stable footing and can move away quickly if a problem arises.

Essential Personal Protective Equipment (PPE)

While a correct setup is foundational, PPE protects you from unforeseen events. The energy stored in a component under pressure is immense, and you must be prepared for a sudden release.

Eye and Face Protection

This is the most critical piece of PPE. A shattering workpiece can send shrapnel flying in all directions.

- Safety Glasses: At a minimum, wear ANSI Z87.1-rated safety glasses with side shields.

- Face Shield: For any operation where a fracture is possible, a full-face shield worn over safety glasses provides a crucial extra layer of protection.

Hand Protection

Hydraulic presses create powerful pinch points, and the materials being worked on often have sharp edges.

- Heavy-Duty Gloves: Wear impact-resistant work gloves to protect against crushing and cuts when handling the workpiece. Never wear them if there is a risk of entanglement with rotating parts, though this is rare on standard presses.

Foot Protection

The components used with a hydraulic press, such as dies, plates, and the workpieces themselves, are often extremely heavy.

- Steel-Toed Boots: Certified safety boots are mandatory to protect your feet from crushing injuries caused by a dropped object.

Understanding the Common Safety Failures

Trust in your equipment and process is built by understanding how things can go wrong. Avoiding these common pitfalls is as important as wearing the right gear.

Using Inappropriate Supports

Never use makeshift supports like wood blocks, stacked sockets, or random pieces of steel. They are not rated for press loads and can shatter or slip without warning, causing the workpiece to be ejected violently.

Off-Center Loading

Placing the workpiece off-center applies uneven stress to the press frame and the workpiece itself. This can cause the workpiece to "banana" or shoot out from the side of the press. Always ensure the load is applied through the central axis of the ram.

Ignoring Warning Signs

A hydraulic press will often give warning signs before a major failure. Pay attention to creaking or groaning sounds, leaking hydraulic fluid, or a pressure gauge that is behaving erratically. Stop immediately and investigate if you notice anything unusual.

Complacency and Rushing

Familiarity can lead to complacency. Rushing through a "quick and easy" job is often when safety procedures are skipped and accidents happen. Treat every single operation with the same methodical, safety-first approach.

Making the Right Choice for Your Goal

Your approach to safety should be holistic, combining procedure with personal protection. Use this checklist to ensure you are covered.

- If your primary focus is personal protection: Always wear ANSI-rated safety glasses (or a face shield), heavy-duty gloves, and steel-toed boots before you begin work.

- If your primary focus is preventing catastrophic failure: Always verify the workpiece is centered, properly supported on rated press plates, and that the load is well within the machine's capacity.

- If your primary focus is operational discipline: Always clear the work area of clutter, ensure all machine guards are in place, and never place your hands in the path of the press ram.

A methodical and respectful approach is the ultimate safeguard when harnessing the power of a hydraulic press.

Summary Table:

| Safety Category | Essential Items & Actions | Key Purpose |

|---|---|---|

| Personal Protective Equipment (PPE) | ANSI Z87.1 safety glasses, face shield, heavy-duty gloves, steel-toed boots | Protect against shrapnel, crushing, and impact injuries |

| Machine & Workpiece Setup | Centered loading, rated press plates, pressure within machine limits | Prevent catastrophic failure and workpiece ejection |

| Operational Discipline | Clear work area, proper body positioning, no hands in danger zone | Ensure safe operation and quick response to issues |

Ensure your lab's hydraulic press operations are safe and efficient with KINTEK's expert support. We specialize in providing durable lab equipment and consumables tailored to your needs. Our team can help you select the right safety accessories and press components to maintain a secure working environment. Don't compromise on safety—contact us today to discuss how we can support your laboratory's requirements with reliable solutions from KINTEK.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

People Also Ask

- Why are KBr pellets used in FTIR? Achieve Clear, Accurate Solid Sample Analysis

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation