Titanium vaporizes at a temperature of approximately 3287°C (5949°F). This transformation from liquid to gas, known as the boiling point, occurs under standard atmospheric pressure. It represents an incredibly high thermal threshold, a key characteristic that defines both the material's greatest strengths and its most significant manufacturing challenges.

Understanding titanium's boiling point is less about a single number and more about appreciating its entire thermal profile. This extreme temperature resistance is the very reason it is chosen for critical applications, but it also dictates the complex and energy-intensive methods required to work with it.

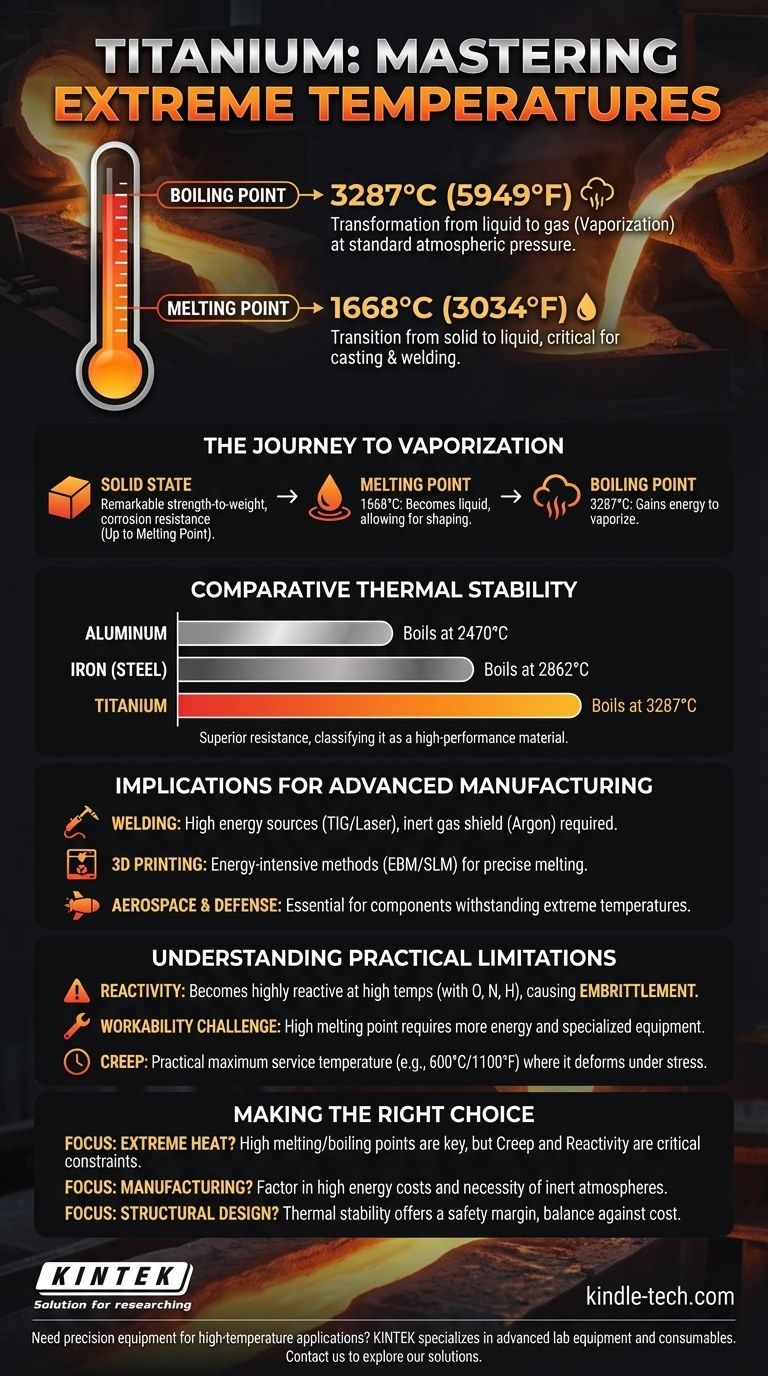

The Journey to Vaporization

A material's transition from solid to gas is a process with distinct stages. For titanium, each stage occurs at temperatures that far exceed those of common structural metals, highlighting its exceptional thermal stability.

The Solid State

At room temperature and up to its melting point, titanium is known for its remarkable strength-to-weight ratio and corrosion resistance. This is the state in which it is used for most structural applications.

The Melting Point: Transition to Liquid

Before titanium can boil, it must first melt. The melting point of titanium is 1668°C (3034°F). At this temperature, it transitions from a solid to a liquid state, a critical parameter for processes like casting and welding.

The Boiling Point: From Liquid to Gas

Once in a liquid state, the temperature must continue to rise significantly to reach the boiling point. At 3287°C (5949°F), the liquid titanium gains enough energy to transform into a gaseous vapor.

Why This Extreme Temperature Matters

The exceptionally high melting and boiling points of titanium are not just academic data points; they are fundamental to its most critical real-world uses.

A Benchmark for Thermal Stability

To put titanium's properties in perspective, consider how it compares to other common metals:

- Aluminum boils at 2470°C.

- Iron (the primary component of steel) boils at 2862°C.

- Titanium boils at 3287°C.

This superior resistance to heat is a primary reason it's classified as a high-performance material.

Implications for Advanced Manufacturing

This thermal resilience makes titanium difficult to process.

- Welding requires very high energy sources (like TIG or laser) and must be done in an inert gas shield (like argon) to prevent contamination.

- 3D Printing with titanium often involves energy-intensive methods like electron-beam melting (EBM) or selective laser melting (SLM) to precisely melt and fuse the metal powder.

Dominance in Aerospace and Defense

Applications like jet engine components, turbine blades, and spacecraft airframes rely on materials that can withstand extreme temperatures without failing. Titanium's ability to maintain its structural integrity well past the limits of aluminum alloys makes it indispensable in these fields.

Understanding the Practical Limitations

While its thermal resistance is a major advantage, it also introduces significant trade-offs that must be managed in engineering and manufacturing.

Reactivity at High Temperatures

Despite being highly corrosion-resistant at room temperature, titanium becomes very reactive with oxygen, nitrogen, and hydrogen at elevated temperatures. This can cause embrittlement, severely compromising the material's integrity. This is why controlled atmospheres are non-negotiable for high-temperature processing.

The Challenge of Workability

The same properties that make titanium strong and heat-resistant also make it difficult and expensive to machine, form, and join. Its high melting point demands more energy and specialized equipment than conventional metals like steel or aluminum.

Creep: The True Service Temperature Limit

In practice, the maximum temperature a material can be used at is often determined by its creep resistance. Creep is the tendency of a material to slowly deform over time under stress at high temperatures. For most titanium alloys, the practical maximum service temperature is well below the melting point, typically in the range of 600°C (1100°F), beyond which it begins to lose its useful strength.

Making the Right Choice for Your Goal

Understanding the full thermal profile of titanium allows you to select and process it effectively for your specific application.

- If your primary focus is extreme heat resistance: Titanium's high melting and boiling points are a clear advantage, but the practical service limit defined by creep and high-temperature reactivity is the more critical design constraint.

- If your primary focus is manufacturing: You must factor in the high energy costs and the absolute necessity of inert atmospheres to prevent contamination and material failure during welding or printing.

- If your primary focus is structural design: Titanium's thermal stability provides a significant safety margin, but it must be balanced against its higher cost and processing complexity compared to steel for applications not requiring its extreme performance.

Ultimately, leveraging titanium successfully comes from respecting its properties and acknowledging that its greatest strengths are intrinsically linked to its greatest challenges.

Summary Table:

| Thermal Property | Temperature (°C) | Temperature (°F) |

|---|---|---|

| Melting Point | 1668°C | 3034°F |

| Boiling Point | 3287°C | 5949°F |

Need precision equipment for high-temperature applications like titanium processing? KINTEK specializes in advanced lab equipment and consumables designed to meet the demanding needs of aerospace, defense, and materials science laboratories. Our high-temperature furnaces, controlled atmosphere systems, and durable consumables ensure reliable performance under extreme conditions. Contact us today to explore how our solutions can enhance your research and manufacturing processes!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

- 1700℃ Laboratory Quartz Tube Furnace with Alumina Tube Tubular Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 1200℃ Muffle Furnace Oven for Laboratory

People Also Ask

- What is a vacuum furnace used for? Unlock Purity in High-Temperature Processing

- Can I vacuum the inside of my furnace? A Guide to Safe DIY Cleaning vs. Professional Service

- What materials are used in a vacuum furnace? A Guide to Hot Zone Materials and Processed Metals

- Why do you vacuum for heat treatment? Achieve Flawless, High-Performance Metal Components

- What materials are used in a vacuum furnace? Selecting the Right Hot Zone for Your Process