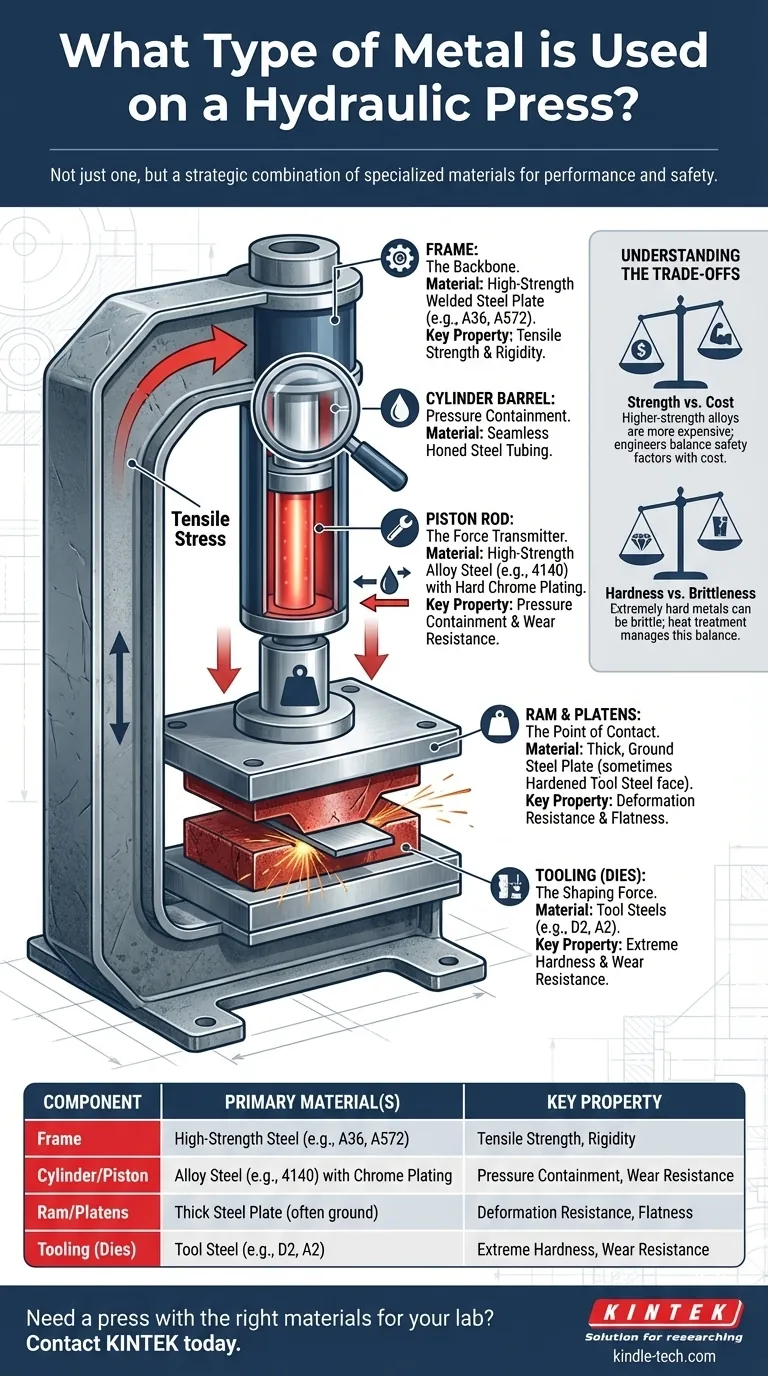

The short answer is that a hydraulic press is not made from a single metal, but from a combination of specialized materials. The primary material is high-strength structural steel for the frame, with harder, wear-resistant steel alloys and sometimes cast iron used for critical components like the cylinder, piston, and tooling.

The selection of metal for a hydraulic press is a deliberate engineering choice driven by function. Each part of the press endures different types of stress, requiring a specific balance of strength, hardness, and wear resistance to operate safely and effectively under immense pressure.

Why a Press Demands Specialized Materials

A hydraulic press operates by converting fluid pressure into immense mechanical force. This process subjects the machine's components to extreme compressive and tensile stresses that would cause ordinary metals to bend, deform, or catastrophically fail.

The material for each component is therefore chosen based on the specific job it must do, ensuring the machine can withstand repeated, high-tonnage cycles without compromising safety or performance.

A Component-by-Component Material Breakdown

Understanding the materials used in a press is best done by looking at its core components, as each has a unique role and set of requirements.

The Frame: The Backbone of the Press

The frame is the main structure that contains and resists the immense force generated by the hydraulic system. It experiences tremendous tensile stress (being pulled apart) during a pressing operation.

For most modern C-frame or H-frame presses, the material of choice is a high-strength, welded steel plate. Steel alloys like ASTM A36 or higher-grade HSLA (High-Strength Low-Alloy) steels like A572 are common because they offer an excellent combination of strength, toughness, and weldability, allowing for strong, rigid construction.

The Hydraulic Cylinder and Piston: The Heart of the Force

The cylinder must contain extremely high-pressure hydraulic fluid without expanding or bursting. The piston rod must transmit this force while sliding smoothly and resisting wear.

The cylinder barrel is typically made from seamless honed steel tubing, which has a smooth internal finish and is rated for high pressures. The piston rod is usually a high-strength steel bar (like 4140 alloy steel) that has been induction-hardened and then coated with hard chrome plating. This plating provides an incredibly hard, low-friction, and corrosion-resistant surface.

The Ram and Platens: The Point of Contact

The ram (or platen) is the moving surface that directly contacts the workpiece or tooling. It must be perfectly flat and resist deformation under the full tonnage of the press.

These components are typically made from thick, high-strength steel plates that have been surface-ground for flatness. In high-precision or high-wear applications, they may be made from or faced with hardened tool steel.

The Tooling (Dies): The Shaping Force

The dies or tooling are the parts that actually shape the workpiece. They must be significantly harder than the material being pressed and must resist chipping, cracking, and abrasive wear over thousands of cycles.

This is the domain of tool steels. Specific alloys like D2 (high-carbon, high-chromium) are chosen for their extreme hardness and wear resistance, while others like A2 are chosen for a good balance of hardness and toughness.

Understanding the Trade-offs

The choice of metal is never made in a vacuum. Engineers must balance competing factors to produce a safe, effective, and economical machine.

Strength vs. Cost

Higher-strength steel alloys are more expensive. A manufacturer must select a material that provides a sufficient safety factor without making the press prohibitively costly. This is why a 20-ton shop press and a 2,000-ton industrial forging press are built to different material standards.

Hardness vs. Brittleness

There is often a trade-off between a material's hardness and its toughness. An extremely hard metal might be brittle, meaning it could shatter under a sharp impact. The heat treatment and specific alloy choice for components like tooling are carefully managed to achieve the required hardness without sacrificing the toughness needed to avoid catastrophic failure.

Cast Iron vs. Steel

While most modern presses use welded steel frames, very large or older presses sometimes use cast iron frames. Cast iron is excellent at damping vibrations and can be cast into complex shapes. However, it has lower tensile strength than steel and is more brittle, making fabricated steel the dominant choice for most new designs today.

Making the Right Choice for Your Application

Understanding these materials helps you evaluate a press based on its intended use.

- If your primary focus is general shop work: A press with a solid, welded steel frame (often A36 steel) and a hard-chrome piston is the reliable industry standard.

- If your primary focus is high-precision industrial forming: Look for presses with thick, ground steel platens and verify that the cylinder and piston materials are rated for continuous, high-cycle use.

- If you are designing or building a press: Prioritize the engineering calculations for the frame and cylinder above all else. Using underrated materials is the most common cause of dangerous failures in homemade equipment.

Ultimately, the sophisticated use of different metals is what allows a hydraulic press to safely contain and precisely deliver astonishing amounts of force.

Summary Table:

| Component | Primary Material(s) | Key Property |

|---|---|---|

| Frame | High-Strength Steel (e.g., A36, A572) | Tensile Strength, Rigidity |

| Cylinder/Piston | Alloy Steel (e.g., 4140) with Chrome Plating | Pressure Containment, Wear Resistance |

| Ram/Platens | Thick Steel Plate (often ground) | Deformation Resistance, Flatness |

| Tooling (Dies) | Tool Steel (e.g., D2, A2) | Extreme Hardness, Wear Resistance |

Need a Hydraulic Press Built with the Right Materials for Your Lab?

The precise selection of metals is critical for the safety, performance, and longevity of your hydraulic press. KINTEK specializes in lab equipment and consumables, offering expert guidance and robust solutions tailored to your specific laboratory needs—from material testing to sample preparation.

Let our experts help you select a press engineered for your application. Contact KINTEK today to discuss your requirements and ensure you get a machine built with the quality and durability you can count on.

Visual Guide

Related Products

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is a sintering process? A Guide to Fusing Powders into High-Performance Parts

- How much psi can a hydraulic press make? From 2,000 PSI to over 50,000 PSI Explained

- Does a hydraulic press have heat? How Heated Platens Unlock Advanced Molding and Curing

- What does a hydraulic heat press do? Achieve Industrial-Scale, Consistent Pressure for High-Volume Production

- What is a hot hydraulic press? Harness Heat and Pressure for Advanced Manufacturing