When a diamond is placed in a hydraulic press, it shatters. Despite its reputation as the hardest natural substance, a diamond is not indestructible. The immense and uniform compressive force generated by the press exploits the diamond's key structural weakness—its brittleness—causing it to catastrophically fail and fracture into small pieces or dust.

The common confusion lies in the difference between a material's hardness (its ability to resist scratching) and its toughness (its ability to resist shattering). A hydraulic press doesn't try to scratch the diamond; it crushes it, and a diamond's atomic structure is simply too rigid to withstand that type of overwhelming force.

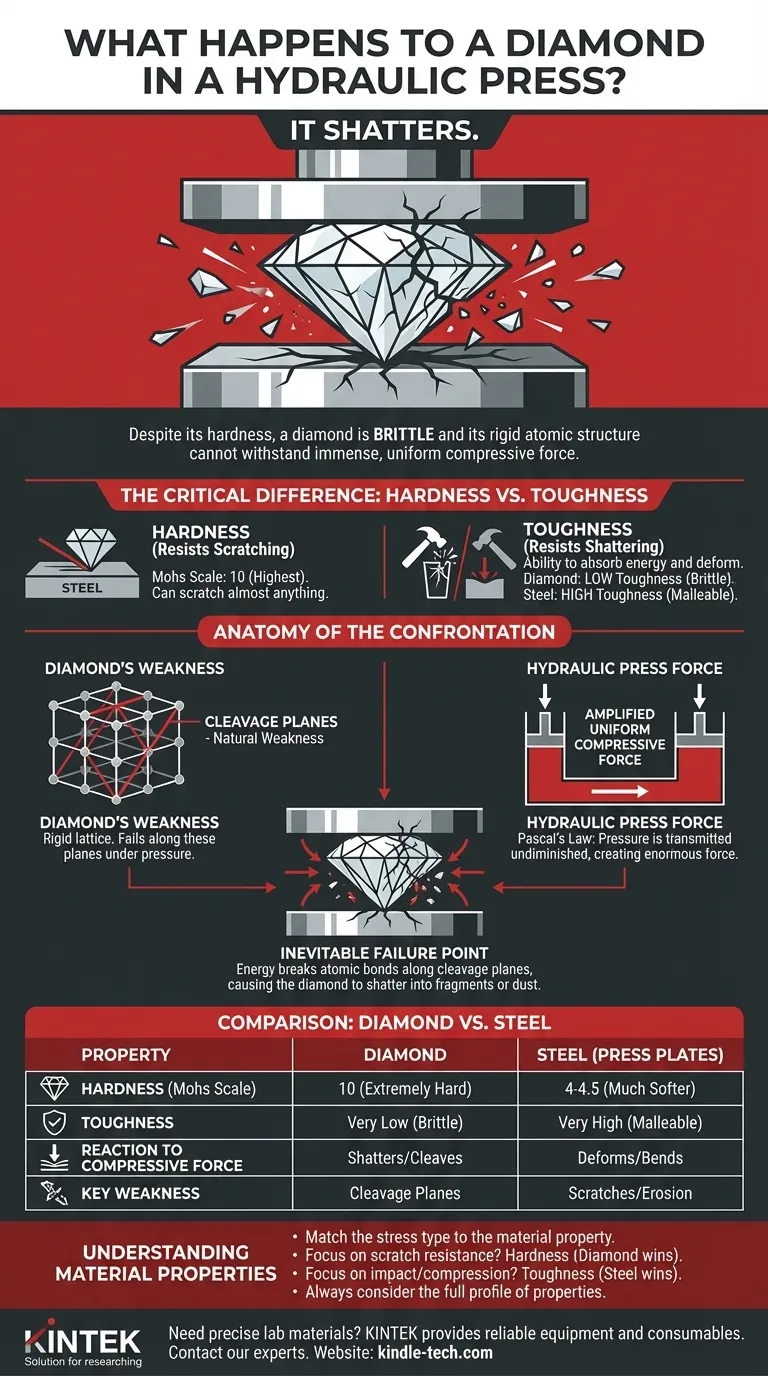

The Critical Difference: Hardness vs. Toughness

To understand why a diamond breaks, we must first clarify the properties that define a material's strength. These terms are often used interchangeably in casual conversation, but in material science, they mean very different things.

What "Hardness" Really Means

Hardness is a measure of a material's resistance to localized surface deformation, such as scratching or indentation. On the Mohs scale of mineral hardness, diamond scores a perfect 10.

This means a diamond can scratch virtually any other material, including the hardened steel plates of a hydraulic press. This property is why diamonds are used in industrial cutting, grinding, and drilling tools.

The Concept of Toughness and Brittleness

Toughness, on the other hand, is a material's ability to absorb energy and deform without fracturing. Materials with high toughness can bend or dent when force is applied, while materials with low toughness are brittle.

A diamond is extremely brittle. Think of it like glass: it's quite hard and can scratch many surfaces, but it shatters easily if struck with a hammer. It cannot bend or deform to absorb pressure; instead, it breaks.

How a Diamond's Structure Causes This

A diamond's strength and weakness both come from its perfect crystal lattice. It is a rigid, tightly bonded structure of carbon atoms.

While these bonds are incredibly strong, they create what are known as cleavage planes—natural, flat planes of structural weakness within the crystal. When overwhelming force is applied, the diamond will split cleanly along these planes rather than deforming.

Anatomy of the Confrontation: Press vs. Diamond

The outcome is determined by the nature of the force applied by the press and the way the diamond's structure responds to that specific type of force.

The Unrelenting Force of the Press

A hydraulic press operates on Pascal's Law, which states that pressure applied to an enclosed fluid is transmitted undiminished to every portion of the fluid.

By applying a small force to a small piston, the press generates a massive, amplified compressive force in a larger piston. This creates an enormous and evenly distributed amount of pressure on any object placed between its plates.

The Diamond's Response to Pressure

When the press begins to apply force, the diamond's rigid structure fiercely resists compression. It has an exceptionally high bulk modulus, meaning it takes an immense amount of pressure to reduce its volume even slightly.

However, the force from the press continues to build, far exceeding what the diamond's internal structure can tolerate.

The Inevitable Failure Point

Once the pressure from the press overcomes the diamond's inherent compressive strength, the energy has to go somewhere. Since the rigid lattice cannot bend, the energy is channeled into breaking the atomic bonds along its cleavage planes.

The result is a catastrophic failure. The diamond doesn't dent the steel; it shatters, often with explosive force, into numerous smaller fragments.

Understanding the Trade-offs of Material Properties

The contest between a diamond and a hydraulic press is a perfect illustration of why no single material is perfect for all applications. Each has strengths and weaknesses that are exposed by different conditions.

The Malleability of Steel

The steel plates of the press are far less hard than the diamond, but they are immensely tough and malleable. They can withstand enormous compressive forces and would deform or bend long before they would shatter. This toughness is what makes steel a foundational material for construction and machinery.

Why a Diamond Can Cut Steel, But Not Withstand Its Pressure

A diamond can cut steel because its superior hardness allows it to focus an incredible amount of force onto a microscopic point, breaking the bonds in the steel's surface.

However, when the press applies force, the stress is distributed over the whole diamond. This changes the contest from one of hardness (scratching) to one of compressive strength and toughness, where the brittle diamond is at a profound disadvantage against the tough steel.

Applying This to Your Understanding of Materials

To accurately predict how materials will interact, you must match the type of stress with the correct material property.

- If your primary focus is scratch resistance: Hardness is the critical property, and in this regard, a diamond is nearly unmatched.

- If your primary focus is impact or compression resistance: Toughness and compressive strength are what matter, and a brittle material like diamond will fail.

- If you want to understand any interaction: Always consider the type of force being applied (sharp, blunt, sustained, impact) against the full profile of a material's properties.

Ultimately, understanding the distinction between a material's hardness and its toughness is the key to predicting how it will behave under stress.

Summary Table:

| Property | Diamond | Steel (Press Plates) |

|---|---|---|

| Hardness (Mohs Scale) | 10 (Extremely Hard) | 4-4.5 (Much Softer) |

| Toughness | Very Low (Brittle) | Very High (Tough/Malleable) |

| Reaction to Compressive Force | Shatters/Cleaves | Deforms/Bends |

| Key Weakness | Cleavage Planes | Scratches/Erosion |

Need precise, durable materials for your laboratory applications?

At KINTEK, we understand that the right material choice is critical for your lab's success. Whether you require equipment that demands exceptional hardness for cutting or incredible toughness to withstand immense pressure, we have the expertise and solutions to meet your specific needs.

Let KINTEK provide the reliable lab equipment and consumables that your research depends on.

Contact our experts today to discuss how we can support your laboratory's unique challenges.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- What are the errors in XRF? Master Sample Preparation for Accurate Results

- What are the samples for XRF analysis? A Guide to Preparing Solids, Powders, and Liquids

- What is the purpose of using a laboratory hydraulic press for dry pressing SiC? Master Pre-Forming for Hot Pressing

- What is the application of a laboratory hydraulic press in PHA testing? Perfecting Biopolymer Material Analysis

- What is the use of potassium bromide KBr? From Historic Medicine to Modern Lab Essential

- What role does a laboratory hydraulic press play in all-solid-state battery fabrication? Enhancing Ion Conductivity

- Why is a laboratory hydraulic press used to briquette the mixture? Enhance Magnesium Extraction Efficiency

- What are the two methods of preparation of IR sample? A Guide to KBr Pellets and Nujol Mulls