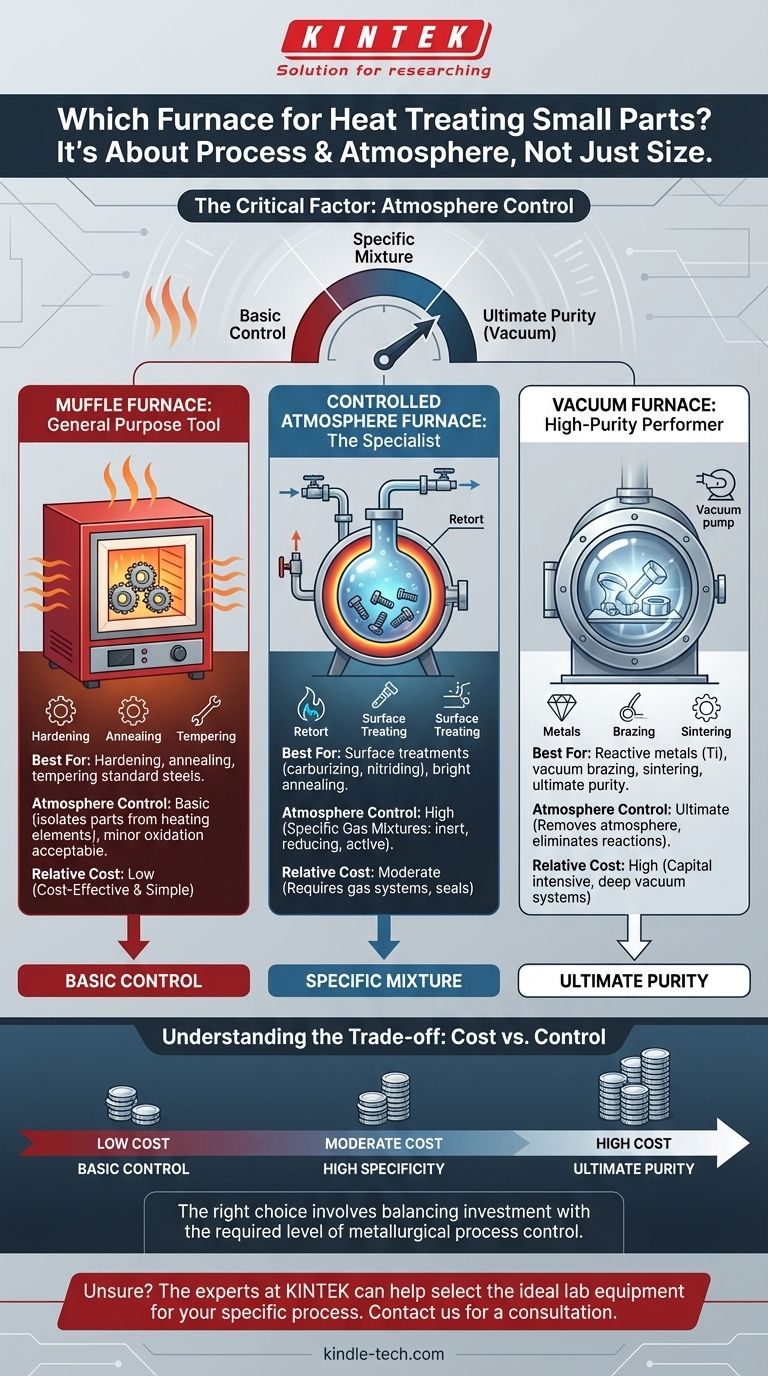

For the heat treatment of small parts, a muffle furnace is the most common and versatile choice for general-purpose applications. However, for processes requiring specific atmospheric conditions or ultimate purity, a vacuum furnace or a controlled atmosphere furnace is the correct tool. The best furnace is determined not by the part's size alone, but by the required metallurgical process.

The critical factor in selecting a furnace for small parts is not the physical dimension of the component, but the level of atmosphere control the heat treatment process demands. Your choice moves from a simple muffle furnace to a complex vacuum furnace as the need to prevent surface reactions like oxidation increases.

Why "Small Parts" Is Only the Starting Point

The term "small parts" is a physical descriptor, but heat treatment is a metallurgical process. The furnace must be chosen based on the desired outcome for the metal, which is almost always linked to how the furnace atmosphere interacts with the part's surface at high temperatures.

Two factors are more important than size: the heat treatment process (e.g., hardening, annealing, tempering) and the material's sensitivity to its environment.

The Critical Role of the Furnace Atmosphere

At high temperatures, metal surfaces are highly reactive. An uncontrolled atmosphere, like plain air, will cause oxidation (scaling) and can alter the surface chemistry of the steel, for example by removing carbon (decarburization), which softens the surface.

The primary function of a specialized furnace is to control this atmosphere, either by replacing it with a specific gas, an inert gas, or by removing it entirely (a vacuum).

Common Furnace Types for Small Parts

Based on the level of control needed, three primary furnace types are used for treating small components.

The Muffle Furnace: The General-Purpose Tool

A muffle furnace contains a sealed inner chamber (the "muffle") that is heated from the outside. The parts are placed inside this muffle, isolating them from direct contact with the heating elements and combustion byproducts.

This design is simple, cost-effective, and excellent for basic processes like tempering, stress-relieving, and hardening common steels where minor surface oxidation is acceptable or can be removed later.

The Controlled Atmosphere Furnace: The Specialist

For processes that require a specific, active gaseous environment, a controlled atmosphere furnace is necessary. These are often retort furnaces, which feature a sealed inner vessel that can be filled with a precise gas mixture.

These are used for surface modification treatments like carburizing (adding carbon), nitriding (adding nitrogen), or for bright annealing/hardening using inert or reducing gases to completely prevent oxidation.

The Vacuum Furnace: The High-Purity Performer

A vacuum furnace provides the ultimate level of atmospheric control by removing it almost entirely. By operating under a deep vacuum, it eliminates virtually all gases that could react with the metal parts.

This is essential for heat treating reactive metals (like titanium or certain superalloys) or for processes like vacuum brazing and sintering. The result is a perfectly clean, bright surface finish with no oxidation or decarburization.

A Note on Handling: Furnace Baskets

For any of these furnaces, small parts are almost always loaded in specialized heat-resistant baskets. These allow for easy loading, ensure uniform heating, and facilitate rapid transfer to a quenching tank if required for hardening.

Understanding the Trade-offs: Cost vs. Control

Your choice of furnace involves a direct trade-off between the initial investment and the level of process control you achieve.

Muffle Furnaces: Low Cost, Basic Control

These are the most affordable and straightforward furnaces. Their main limitation is that achieving a perfectly inert atmosphere is difficult, making them unsuitable for materials that cannot tolerate any surface oxidation.

Controlled Atmosphere Furnaces: Moderate Cost, High Specificity

These systems are more complex and expensive due to the need for gas-tight seals, gas mixing panels, and safety systems. Their value lies in enabling specific surface chemistry changes that are otherwise impossible.

Vacuum Furnaces: High Cost, Ultimate Purity

Vacuum furnaces represent the highest capital investment. The cost is driven by the vacuum chamber, powerful pumping systems, and sophisticated controls. They are non-negotiable for high-performance applications where material purity is the top priority.

Making the Right Choice for Your Goal

To select the correct furnace, first define your technical and commercial requirements.

- If your primary focus is general-purpose hardening, annealing, or tempering of standard steels: A muffle furnace provides the best balance of cost and capability.

- If your primary focus is a specific surface treatment like carburizing or bright hardening: A controlled atmosphere furnace is the necessary tool for the job.

- If your primary focus is processing reactive metals, high-purity brazing, or achieving a perfectly bright finish: A vacuum furnace is the only option that can meet these requirements.

Ultimately, choosing the right furnace begins by defining the desired metallurgical result, not just the size of the part.

Summary Table:

| Furnace Type | Best For | Atmosphere Control | Relative Cost |

|---|---|---|---|

| Muffle Furnace | General hardening, annealing, tempering of standard steels | Basic (isolates parts) | Low |

| Controlled Atmosphere | Carburizing, nitriding, bright annealing | High (specific gas mixtures) | Moderate |

| Vacuum Furnace | Reactive metals (titanium), brazing, ultimate purity | Ultimate (removes atmosphere) | High |

Unsure which furnace is right for your small parts? The experts at KINTEK can help. We specialize in providing the ideal lab equipment for your specific heat treatment processes, whether you need a cost-effective muffle furnace or a high-purity vacuum system. Contact our team today for a personalized consultation to ensure you achieve the perfect metallurgical results.

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- Vertical Laboratory Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Multi-zone Laboratory Tube Furnace

People Also Ask

- What is the calcination process? A Guide to Thermal Purification and Material Transformation

- What temperature is required for calcination? Master Material-Specific Thermal Decomposition

- What is the effect of temperature on calcination? Master Precise Heat Control for Material Properties

- What is the effect of calcination? Unlock Material Transformation for Industrial Processes

- Why refractory materials are used in furnaces? Ensure Safety, Efficiency, and Process Purity